Emerson DeltaV ™ Electronic Marshalling for Migrations

Emerson DeltaV ™ Electronic Marshalling for Migrations

Core positioning and core advantages

The electronic grouping for DeltaV migration is built on CHARM I/O cards (CIOC) and designed specifically for the migration of traditional control systems to DeltaV systems. With "high flexibility, low transformation cost, and full redundancy and reliability" as the core, it achieves in-situ replacement and efficient integration of I/O modules. The core advantages can be summarized as six key features:

Flexible deployment of I/O: CIOC supports 1:1 direct replacement within the same space as traditional I/O, without the need for new cabinets, customized cables, or additional grouping; I/O can be installed in any adaptive position of the existing cabinet as needed, adapting to the layout requirements of different migration scenarios.

Single channel refined configuration: The CHARM I/O architecture supports independent adaptation of field device requirements for each channel. Any instrument signal can be connected to any terminal block, and electronic grouping can be completed by installing the corresponding CHARM module and assigning it to up to 4 controllers; No need to split traditional panel signals into multiple DeltaV I/O cards, solving the problem of adapting traditional I/O terminals.

In situ replacement of traditional I/O: The migration panel can be installed above, below, or even in front of the traditional terminal panel, and the migration can be completed by simply moving the wires a few inches; As a standard CHARM motherboard, the migration panel communicates with CIOC through cable interfaces and is suitable for vertical or horizontal installation (supported in some scenarios), without the need to stretch I/O cables, ensuring smooth system switching.

Fully redundant communication architecture: Full link redundancy from the CHARM channel to the DeltaV controller, including dual I/O cards on the carrier, redundant communication modules (primary/backup network connections), dual 24V DC input power supplies, and redundant power and communication buses provided by the carrier to the CHARM backplane, ensuring high system reliability.

Complete DeltaV solution: After migration, the system is built entirely on DeltaV standard hardware, without mixed custom software and hardware. It can be supported by existing DeltaV operation and maintenance personnel using unified spare parts, reducing maintenance complexity and costs in the later stage.

Plug and play I/O: At the hardware level, components are quickly assembled through DIN rail locks and interlocking carrier connectors; At the software level, after inserting CHARM, the system automatically recognizes the node and generates I/O definitions in the configuration database. The CHARM self key control system avoids accidental insertion; Support drag and drop operations to assign any number of channels to the controller, simplifying the configuration process.

Core components and functional details of the product

(1) Core hardware components

CHARM I/O carrier DIN rail installation, supports redundant CHARM I/O card pairs, provides redundant communication modules and dual 24V DC power interfaces, connects to CHARM motherboard and transmits redundant power/communication bus

CHARM I/O cards (CIOC/CIOC2) achieve communication between CHARM and Ethernet I/O networks (connecting M/S/PK series controllers). CIOC has obtained Achilles communication certification level 1; CIOC2 has stronger computing power and has obtained certification level 2, which can directly replace CIOC

CHARM base plate DIN rail installation, including interleaved power and bus connectors supporting 12 CHARMs and terminal blocks, providing on-site injection power interface, compatible with migration panel installation

CHARM terminal block can be disassembled, connected to on-site wiring and fixed. CHARM supports 2/3/4 wire system equipment wiring, and some models include fused injection power function

The CHARM module (Characterization Module) provides basic analog-to-digital conversion, redundant bus connection, and fault isolation for each field signal. It has circuit protection functions (current limiting/melting) and surge protection (in accordance with EMC industry standards), and faults are limited to a single module

Other auxiliary components include cable extenders (flexible adjustment of carrier installation position), backplane terminators (redundant I/O bus terminals), and 19 inch migration panels (compatible with traditional 19 inch cabinets, supporting 2 CIOC or 2 backplane installations) to ensure hardware installation flexibility and bus signal stability

(2) Key functional characteristics

Power supply: On site power is supplied to each CHARM (maximum 100mA per module) through a redundant 24V DC bus; The high current discrete channel can be powered by injecting the bus through the locally integrated power supply on the motherboard.

Maintenance convenience: CHARM can partially pop up to the locked position, disconnect the on-site wiring from the system, and facilitate on-site maintenance or cutting off equipment power; Activate the lock buckle to eject to the positioning position, and close the lock buckle to isolate the on-site wiring.

System scalability: CIOC can connect up to 4 controllers via Ethernet, and adding controllers or reallocating I/O does not require any physical wiring changes; Support online addition of CHARM (any empty space on the motherboard) and CIOC to adapt to changes in I/O requirements during the migration process.

Installation flexibility: CIOC needs to be installed on vertical DIN rails (which can be located on the front and rear sides, upper and lower parts of the cabinet), and cannot be installed horizontally; The height of the CHARM base plate migration component is 3 EIA units (5.25 inches), and the installation location can be flexibly selected (reusing existing cable trays/cable trays, adjacent installation, or reserved spacing).

Hardware specifications and compatibility

(1) Core hardware environment and size specifications

1. CHARM I/O Migration Panel

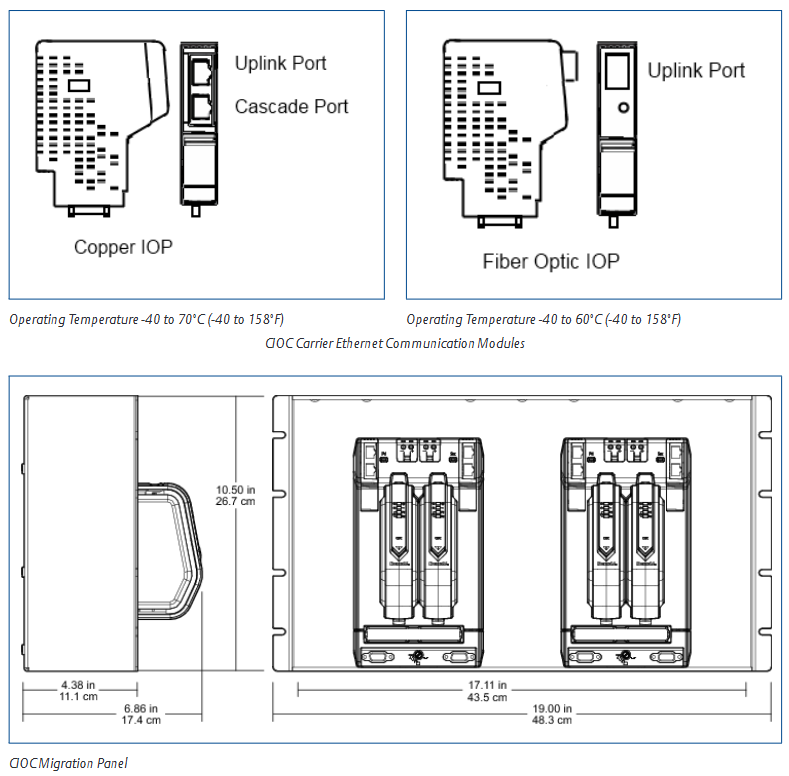

Environmental specifications working temperature: -40~70 ° C (copper Ethernet port), -40~60 ° C (fiber Ethernet port); Storage temperature: -40~85 ° C; relative humidity: 5%~95% (no condensation); Protection level: IP20; Pollutant level: ISA-S71.04-1985 G3 level (with conformal coating); Impact resistance: 10g half sine wave (continuous for 11ms); Vibration: 5-13.2Hz (1mm peak to peak), 13.2-150Hz (0.7g)

Dimensions: Height 10.5 inches (26.7cm), Depth 6.68 inches (17.4cm), Width 19 inches (48.3cm); Installation method: 19 inch EIA rail (6 rack units high)

2. CHARM Bottom Plate Migration Panel

The environmental specifications are consistent with the CHARM I/O migration panel (with a fixed operating temperature of -40~70 ° C)

Dimensions: Height 5.25 inches (13.3cm), Depth 4.8 inches (12.2cm), Width 19 inches (48.3cm); Installation method: 19 inch EIA rail (3 rack units high)

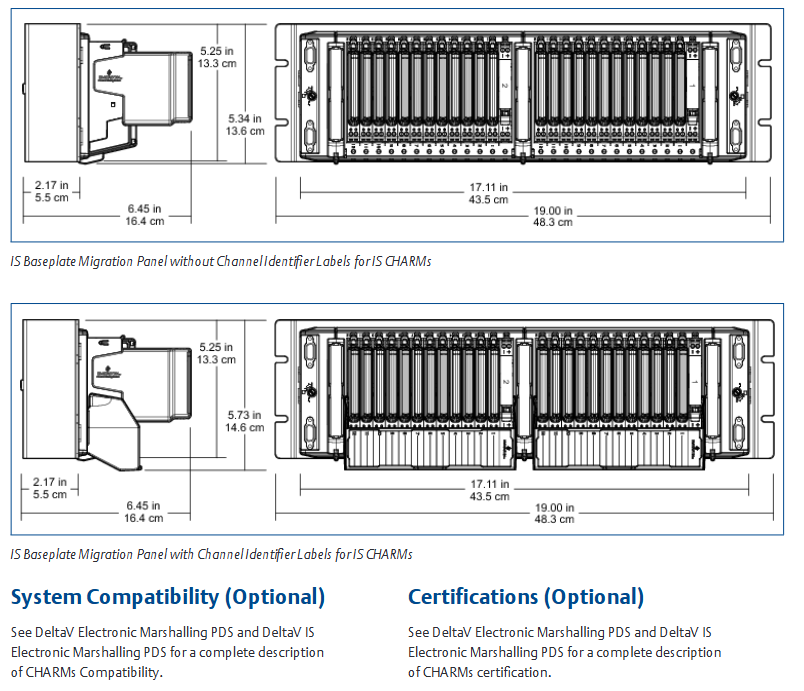

3. IS CHARM Bottom Plate Migration Panel

The environmental specifications are consistent with the above-mentioned bottom migration panel

Size without channel identification label: Height 5.34 inches (13.6cm), Depth 6.45 inches (16.4cm); Channel identification label: height 5.73 inches (14.6cm), depth 6.45 inches (16.4cm); The width is 19 inches (48.3cm), and the installation method is the same as before (3 rack units high)

Special note: The size of IS CHARM is different from non IS models. When installed on a 19 inch panel, it protrudes 45mm from non IS models

(2) System compatibility

Software version requirements: DeltaV electronic grouping hardware must be paired with DeltaV v11.3.1 or higher versions.

Controller adaptation: Supports M-series, S-series, and PK series controllers.

Component compatibility: All CHARM types, IS/non IS I/O terminal blocks, and key control columns are compatible with the migration panel; CIOC2 can directly replace CIOC, and the fiber optic Ethernet I/O ports cannot be cascaded.

Ordering Information and Preconditions

(1) Core Hardware Ordering List (Some Key Models)

CHARM I/O card redundant migration CIOC2 (copper Ethernet), including redundant CIOC2, carrier with screw terminals, copper I/O ports, etc. SE6505T03

CHARM I/O card redundant migration CIOC2 (fiber optic Ethernet), including redundant CIOC2, carrier with screw terminals, fiber optic I/O ports, etc. SE6505T04

Migration panel 19 inch migration panel, supporting 2 redundant migration CIOC SE6503T01

CHARM Base Plate Component Standard Migration Base Plate Component (2 Base Plates, 24 Standard Terminal Blocks, etc.) SE4601T03

CHARM motherboard component with 3-wire DI fuse injection power supply migration motherboard component SE4601T10

CHARM Base Plate Component with Relay Output Migration Base Plate Component SE4601T06

IS CHARM Base Plate IS CHARM Migration Base Plate Component (2 IS Base Plates, 24 IS Standard Terminal Blocks, etc.) SE4608T02

Address plug CHARM Address plug (1-8) SE4602

Address plug CHARM Address plug (1-4) SE4613

Auxiliary component CHARM baseplate top extender (with plug) SE4603T05

Auxiliary component CHARM base plate bottom extender (with socket) SE4603T06

Auxiliary component CHARM base cable (2 pieces, 0.5m) SE4605T02

Auxiliary component DIN rail block (5 pieces/box) VE4054DRS

IS special accessory IS CHARM 24V DC power fuse component SE4610T01 (to be ordered in combination with SE6501T03/SE6501T04 for 2 units)

(2) Pre requirements

Hardware installation must follow DIN rail specifications, and vertical DIN rails must be equipped with a stopper (model VE4054DRS) to fix the position of the base plate.

When using the IS CHARM motherboard, an additional order for SE4610T01 fuse components is required (2 for each CIOC configuration compatible with the IS motherboard).

Fiber optic Ethernet I/O ports cannot be cascaded, and attention should be paid to network topology design.

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor

- SHINKAWA

- Other Brands