Emerson DeltaV M Series MD Plus Controller

Emerson DeltaV M Series MD Plus Controller

Basic Overview

The DeltaV M series MD Plus controller is an industrial control core equipment launched by Emerson Process Management, mainly responsible for communication and control tasks between field devices and other nodes in the control network. It is compatible with the control strategies and system configurations created by early DeltaV systems. On the basis of having all the functions of the M5 Plus controller, it has increased memory capacity to meet the needs of large-scale batch processing and other memory intensive applications. At the same time, it needs to be installed quickly in conjunction with the DeltaV I/O subsystem. The specific execution method of its control language can refer to the product data sheet in the Configuration Software Suite.

Core advantages

(1) Enhance productivity

High performance operation: The computing speed is over 400% faster than the M5 Plus controller, and the user configurable memory is more than three times that of the MD controller; The Ethernet port supports full duplex mode, with a maximum throughput of 100MB/s, which can effectively reduce CPU utilization and improve control strategy processing capability.

Convenient automatic function

Automatic addressing: After connecting to the DeltaV control network, a unique address can be automatically assigned upon power on, without the need for DIP switches or additional configurations, achieving plug and play functionality.

Automatic positioning: The LED lights on the controller panel can flash through operation to visually indicate its physical location, making it easy to locate.

Automatic I/O detection: It can identify all I/O interface channels on the I/O subsystem. After the I/O interface is inserted, it can immediately obtain the basic characteristics of the field devices managed by the interface, reducing useless configuration work.

(2) Strong usability

Comprehensive control capability: not only managing all control activities of I/O interface channels, but also responsible for all communication functions of the communication network, while managing timestamps, alarms, and trend objects. The control strategy execution speed can reach up to once every 100 milliseconds.

Data protection mechanism: When installing data into the controller, relevant installation information will be automatically saved; When users modify the controller configuration online, the system will also store these changes and fully record all data and online modification traces in the controller.

Cold start function: Restarting after power failure does not require manual intervention or assistance from other devices in the network. Simply set the controller restart status to the current working condition to avoid the tedious operation of restarting from the workstation; In addition, it can also be paired with an uninterruptible power supply (UPS) to prevent short-term power outages from interfering with the process.

(3) High flexibility, adaptable to diverse needs

Support advanced operations: compatible with DeltaV Batch options, and can also run advanced control functions such as neural network control and model predictive control.

Data transmission capability: capable of transmitting intelligent HART information from field devices to any workstation node in the control network, supporting applications such as Asset Management Solutions, and achieving remote management of HART information in HART or Foundation fieldbus devices.

System Scalability: As the system size expands, the number of Device Signal Tags (DST) allocated to the controller can be increased by upgrading software licenses, from an initial 50 to 750 (the overall performance and application scale of the controller are affected by the complexity of the control strategy and the scanning rate of the control module); Redundant controllers can also be added online as backups for MD Plus controllers, and the backup controller can automatically switch online without disturbance during the transition process (refer to the "I/O Redundancy" product data sheet for details).

Compatible with legacy system migration: Provides DeltaV platform support for PROVOX and RS3 controller migration, adapting to corresponding migration I/O interfaces. Among them, when migrating the PROVOX system, the original I/O can be retained through the migration I/O interface, supporting up to 750 actual I/O signals. The serial dataset is migrated to the DeltaV serial card, and because the DeltaV system supports direct module reference, there is no need to use virtual I/O anymore; RS3 system migration can also be fully supported through MD Plus controllers and corresponding migration I/O interfaces.

Installation and environmental requirements

(1) Installation related

Installation method: Adopting a modular plug and play structure, system expansion can be achieved on the basis of a single controller. It is installed in the right slot of the 2-wide Power/Controller Carrier and supports installation in Class 1, Div 2 or ATEX Zone II hazardous environments (specific installation details need to refer to "Zone 2 installation instructions (12P2046)" and "Class 1 Division 2 installation instructions (12P1293)").

Supporting requirements: A dedicated installation carrier must be selected for each controller (refer to the "I/O Carrier" product data sheet for details), and each controller must be equipped with an independent system power supply (refer to the "Power Supplies" product data sheet for details).

(2) Environmental parameters

Specific requirements for environmental indicators

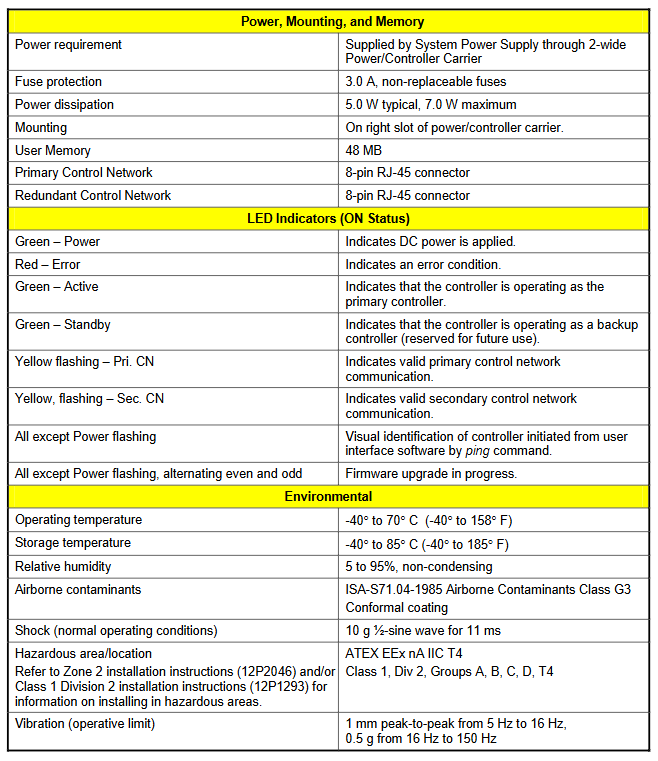

Working temperature -40 ° C~70 ° C (-40 ° F~158 ° F)

Storage temperature -40 ° C~85 ° C (-40 ° F~185 ° F)

Relative humidity 5%~95% (no condensation)

The air pollutants meet the ISA-S71.04-1985 G3 level air pollutant standard and have a conformal coating

Shock (normal working state) 10g half sine wave, lasting for 11 milliseconds

Hazardous area/location level ATEX EEx nA IIC T4, Class 1, Div 2, Groups A, B, C, D, T4 level

When the vibration (working limit) is between 5Hz and 16Hz, the peak to peak value is 1mm; 0.5g at 16Hz~150Hz

Technical specifications

Specific content of technical parameters

The power requirement is supplied by the system power supply through a 2-wide Power/Controller Carrier

Fuse protection 3.0A non replaceable fuse

Typical power consumption is 5.0W, maximum value is 7.0W

User memory 48MB

Main control network interface 8-pin RJ-45 connector

Redundant control network interface 8-pin RJ-45 connector

LED indicator light (meaning lit) - green (power): indicates that the DC power supply has been connected

-Red (Error): Indicates the existence of an error status

-Green (Active): indicates that the controller is running as the main controller

-Green (Standby): indicates that the controller is running as a backup controller (reserved function, not yet enabled)

-Yellow flashing (Pri. CN): indicates normal communication in the main control network

-Yellow flashing (Sec. CN): indicates that the backup control network communication is normal

-All flashing except for the power light: triggered by the ping command of the user interface software, used for visual recognition of the controller

-Except for the power light, even and odd digits flash alternately: indicating that a firmware upgrade is in progress

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor

- SHINKAWA

- Other Brands