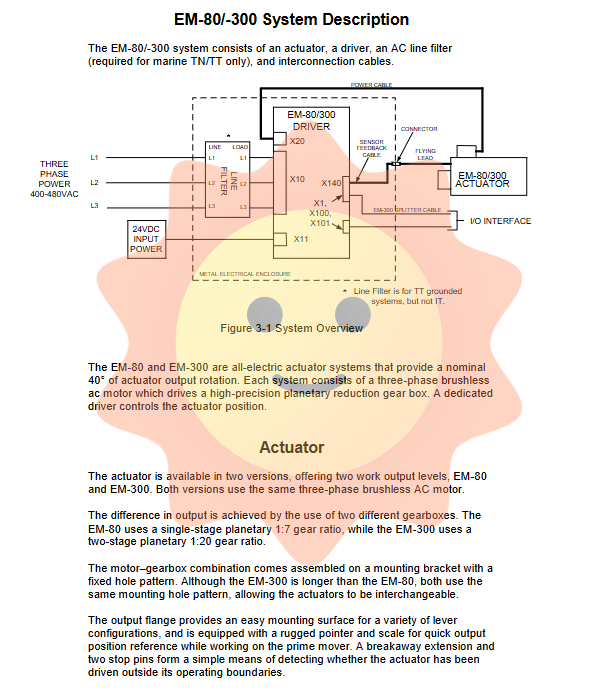

Woodward EM-80/EM-300 actuator system

EM-80 Specifications:

Nominal Torque (Continuous): 91 N·m (67 lb-ft) at up to 40°C ambient.

Maximum Torque (Transient): 190 N·m (140 lb-ft) for a maximum of 1 second.

Slew Time (10-90%): Approximately 78 ms with no load.

EM-300 Specifications:

Nominal Torque (Continuous): 260 N·m (192 lb-ft) at up to 40°C ambient.

Maximum Torque (Transient): 429 N·m (316 lb-ft) for a maximum of 1 second.

Slew Time (10-90%): Approximately 192 ms with no load.

Temperature Derating

A critical aspect of these actuators is their thermal management. While the units are rated for an ambient operating temperature range of 0 to +85°C, their continuous torque output is derated above 40°C.

EM-80: At 40°C, the unit produces 91 N·m. As the temperature rises to the maximum 85°C, the continuous torque capability drops to approximately 55 N·m.

EM-300: At 40°C, the unit produces 260 N·m. At 85°C, the capability drops to approximately 158 N·m.

Transient torque (peak torque) remains available across the entire temperature range, but operators must ensure that applications requiring high sustained torque do not exceed the derated limits, as this will lead to motor overheating, loss of torque, or driver shutdown.

Mechanical Interface and Installation

The physical installation of the EM-80/EM-300 requires careful attention to alignment and mounting surface integrity.

Weight: The EM-80 weighs approximately 35 kg (77 lb), while the EM-300 is slightly heavier at 38 kg (84 lb). Both are equipped with eyebolts for lifting.

Mounting Pattern: Both units use a similar mounting hole pattern. The distance from the front flange to the first row of holes is identical (68.0 mm), ensuring that an EM-80 can be replaced with an EM-300 without rearranging the linkage.

Flatness: The mounting surface must have a flatness of less than 0.2 mm (0.008”). Exceeding this tolerance can induce high stresses in the actuator and mounting bracket when fasteners are torqued.

Orientation: The actuator can be mounted at any angle of rotation about the motor shaft axis, provided the output flange is not more than 45 degrees above or below the opposite end of the actuator.

Stops and Safety

The EM-80 and EM-300 do not have internal mechanical stops. The stroke is electronically limited to 40 degrees. However, the system includes “soft stops” at 47.5 degrees. Inside this zone, the actuator can recover from a power failure and return to the correct working zone. If external forces drive the actuator beyond 47.5 degrees, the system may not be able to re-locate the proper working zone. While the actuator has a protective strip and stop pins to prevent accidental rotation, these stops cannot withstand the actuator’s peak torque.

For safety, it is recommended that external stops be designed into the fuel rack linkage to limit travel between the 40-degree operating range and the 47.5-degree safe range. These stops must be engineered to absorb the kinetic energy of the actuator mass and linkage (up to 15.1 Joules for EM-300).

Driver Installation and Electrical Connections

Proper installation of the driver is as critical as the actuator mounting. The driver must be installed in a metal electrical enclosure grounded (bonded) to earth.

Cabinet Requirements

The driver generates heat and requires adequate cooling.

Ventilation: Airflow must be from bottom to top.

Clearance: A minimum of 100 mm must be maintained above and below the unit, and 5 mm to the left and right.

Ambient Temperature: The driver is rated for 0 to 55°C. If the temperature at 50 mm below the device exceeds 45°C, the device power must be derated by 3% per °C.

Power Supplies

The system utilizes two distinct power inputs:

3-Phase Power (X10 Connector): 400–480 Vac, 50–60 Hz. This provides the muscle for the motor. It should be protected by fuses (e.g., class gG or slow-blow) or circuit breakers.

24 VDC Logic Power (X11 Connector): Required for the internal logic, I/O, and relays. This supply must be capable of 55 W and must be electrically isolated from the chassis for marine certification compliance.

Motor Connections (X20 Connector)

The driver connects to the actuator motor via the X20 connector.

Terminals U, V, W: Connect to the actuator motor phases.

PE: Protective Earth for the motor shield.

Cable Length: While 50 m is acceptable without additional equipment, up to 100 m is permissible provided a line reactor is used to manage cable parasitic capacitance.

Resolver Connections (X140 Connector)

The resolver feedback uses a dedicated DB-15 connector. The cable includes flying leads for the EM-300 potentiometer (POT_V, POT+, POT-). For EM-80 applications, these unused leads must be insulated and secured. The resolver provides excitation and sin/cos feedback signals.

Pins: 1 (Sin+), 3 (Cos+), 6 (Exc+), 9 (Sin-), 11 (Cos-).

Temperature: Pins 7 and 14 carry the motor temperature sensor signal.

Control and I/O Interfaces (X100 & X101)

The driver interfaces with the external control system through several key signals:

Position Command (X100, Analog Input 1): Accepts a 4–20 mA input corresponding to 0–40 degrees. A 2 kΩ external shunt resistor is required across pins 1 and 3.

Actual Position Readout (X100, Analog Output 2): Provides a 1–5 V signal corresponding to the actuator’s actual position.

Ready for Use Output (X101): A discrete output (usually contact) indicating the system is fault-free and ready.

Common Alarm Output (X101): A discrete output that changes state on fault.

Pulse Enable (X1): An isolated digital input that must be “high” to enable the power stage.

E-Stop (X101): Configurable input (High or Low active) that drives the actuator to minimum position.

Reset (X101): A digital input to acknowledge and clear alarms.

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor

- SHINKAWA