Foxboro Evo ™ FBM217 Discrete Input Module

The FBM217 module and terminal assembly (TA) meet the requirements of harsh industrial environments, with specific parameters as follows:

Environmental Category Module (FBM217) Terminal Assembly (TA) - PVC Material Terminal Assembly (TA) - PA Material

Working temperature -20~+70 ℃ (-4~+158 ° F) -20~+50 ℃ (-4~+122 ° F) -20~+70 ℃ (-4~+158 ° F)

Storage temperature -40~+70 ℃ (-40~+158 ° F) -40~+70 ℃ (-40~+158 ° F) -40~+70 ℃ (-40~+158 ° F)

Relative humidity 5%~95% (no condensation) 5%~95% (no condensation) 5%~95% (no condensation)

Altitude work: -300~+3000m (-1000~+10000ft); Storage: -300~+12000m (-1000~+40000ft) same module same module

The pollution level complies with ISA S71.04 G3 level (harsh environment) and has passed EIA 364-65 Class III exposure testing for the same module

Vibration tolerance 0.75m/s ² (5-500Hz) same module same module

(2) Physical and installation parameters

Module size and weight:

Dimensions: Height 102mm (4in, excluding mounting ears)/114mm (4.5in, including mounting ears), Width 45mm (1.75in), Depth 104mm (4.11in);

Weight: Approximately 284g (10oz), lightweight design facilitates dense installation.

Installation method:

Module: Installed on a DIN rail base plate (supporting 4 or 8 slots), the base plate can be installed horizontally/vertically on a DIN rail, or adapted to a 19 inch rack through an installation kit; Redundant modules need to be installed in odd even positions adjacent to the base plate (such as slots 1-2 and 3-4).

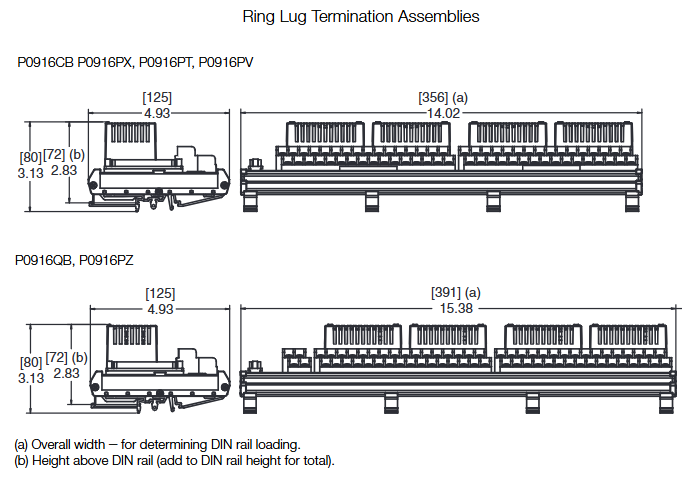

Terminal Assembly (TA): DIN rail mounting, compatible with 32mm (1.26in) and 35mm (1.38in) standard rails, supports compression terminals (24-12 AWG wires) or ring terminal blocks (22-12 AWG wires).

Cable specifications:

Base board to main TA: Use Type 4 cable (37 pin D-sub interface), with a maximum length of 30m (98ft), optional polyurethane (P/PVC), low smoke halogen-free (LSZH) materials, suitable for temperature resistance and environmental protection requirements in different environments;

Main TA to Extended TA: Use Type 6 cable (25 pins on the main TA end and 37 pins on the extended TA end), with a length of 0.75m (2.5ft), only available in LSZH material.

Terminal Assembly (TA) and Compatibility

Terminal assembly (TA) is a key interface between FBM217 and on-site equipment, providing signal conditioning, isolation, and power distribution functions. Different TAs are adapted to different signal scenarios, and the core parameters are as follows:

(1) Classification and adaptation of main terminal assembly (TA)

FBM type input signal type TA model (PVC/PA material) terminal type cable type certification level

FBM217 30V DC Voltage Monitoring (Group Isolation) P0916CA/P0916CB Compression/Ring Lug Type 4 1, 2, 4

FBM217 24V DC contact detection (group isolation) P0916PW/P0916PX (PVC); P0916XZ (PA) Compression/Ring Lug Type 4 1, 2, 4

FBM217 120V AC/125V DC voltage monitoring (channel isolation) P0916PS/P0916PT (PVC); P0916YA (PA) Compression Type 4 1, 4

FBM217 120V AC/125V DC contact detection (group isolation) P0916PY/P0916PZ (PVC); P0916YB (PA) Compression/Ring Lug Type 4 1, 4

FBM217 240V AC Voltage Monitoring (Channel Isolation) P0916PU/P0916PV Compression/Ring Lug Type 4 1

FBM217 240V AC Contact Detection (Group Isolation) P0916QA/P0916QB Compression/Ring Lug Type 4 1

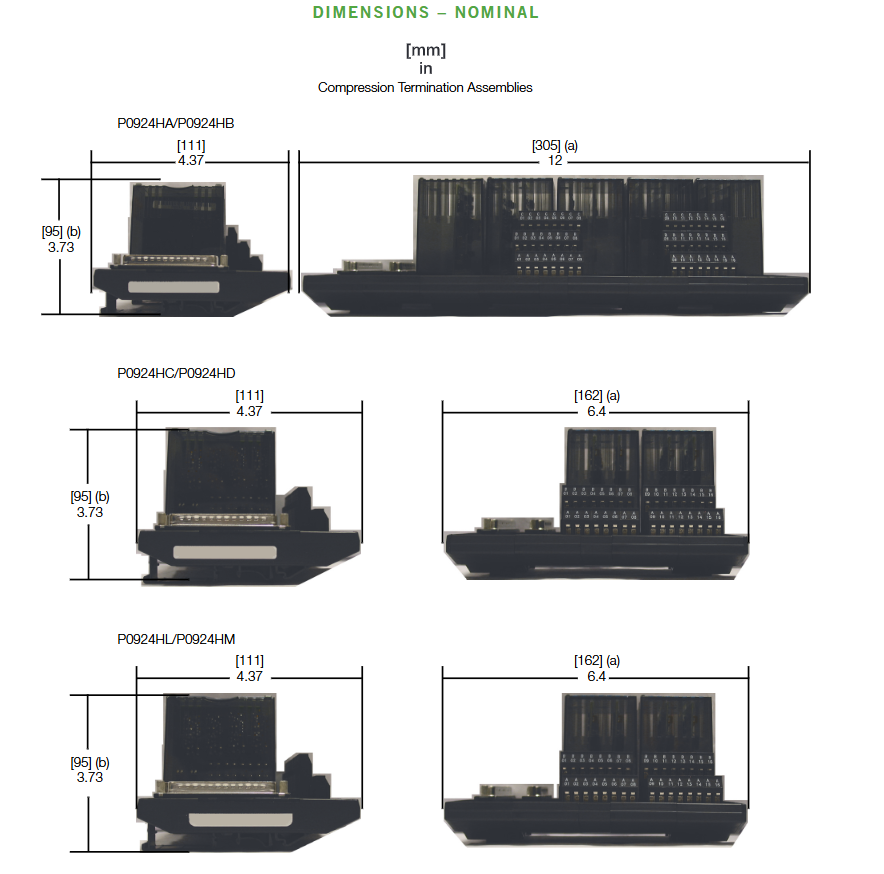

FBM217 replaces FBM07A (15-130V DC voltage monitoring) P0924HA compression type 4 1, 2, 4

FBM217 replaces FBM08 (120V AC/125V DC voltage monitoring) P0924HC compression type 4 1, 4

(2) Expansion Terminal Assembly (TA) adaptation

Expanding TA is used to increase the number of channels and needs to be cascaded with the main TA to adapt to the upgrade of the 100 series extended FBM module. The core models are as follows:

Compatible with 100 series extended FBM input signal specifications, extended TA model (PA material), cable type certification level

FBM12A/B (16 contacts/voltage) with main TA P0924HA P0924HB Type 6 1, 2, 4

FBM13 (16 channel voltage monitoring) with main TA P0924HC P0924HD Type 6 1, 4

FBM21 (16 channel voltage monitoring) with main TA P0924HL P0924HM Type 6 1

FBM25B (16 way contact detection) with main TA P0924HP P0924HS Type 6 1, 2, 4

(3) Certification Level Definition (Table 1)

TA certification strictly follows international safety standards, and different levels correspond to different application scenarios:

Type 1: UL/UL-C certification, suitable for Class I A-D Group 2 hazardous environments (temperature code T4); CENELEC (DEMKO) certification for Zone 2 potentially explosive environments (EEx nA IIC T4).

Type 2: In addition to Type 1, it also meets the requirements of "non flammable on-site circuits" and is compatible with Class 2 limited energy circuits (60V DC/30V AC, ≤ 100VA).

Type 4: All on-site circuits meet Class 2 limited energy requirements and require external equipment to comply with Class 2 restrictions.

Compliance Certification and System Integration

(1) Regulatory Compliance Certification

The FBM217 module and TA have passed multiple international certifications to ensure compliant use in different regions and industries

Electromagnetic compatibility (EMC): Complies with the European EMC Directive 2004/108/EC, meets EN 50081-2 (emission), EN 50082-2 (immunity), EN 61326 (industrial grade) standards, is compatible with CISPR 11 Class A limits, and is resistant to interference such as ESD, radiated fields, and electrical fast transients.

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor

- SHINKAWA

- Other Brands