Foxboro G66 Triconex Tricon Termination Enclosure

Foxboro G66 Triconex Tricon Termination Enclosure: Detailed explanation of industrial grade wiring and protection solutions

In the field of process industry automation, especially in emergency shutdown and combustion management applications involving Safety Instrumented Systems (SIS), the physical protection, wiring density, and environmental adaptability of the control system are crucial. As the flagship product of Schneider Electric's Foxboro brand, the G66 EcoStruxure Triconex Tricon Termination Enclosure (model PSS 41H-2G66) is designed specifically for Tricon G60, G62, and G72 systems to accommodate Triconex terminal devices and customer provided terminal blocks for efficient on-site wiring. This article will deeply analyze the design concept, environmental protection mechanism, thermal management architecture, and power redundancy scheme of the wiring cabinet, demonstrating its excellent performance in harsh industrial environments.

Design concept: A dedicated wiring platform for the Tricon system

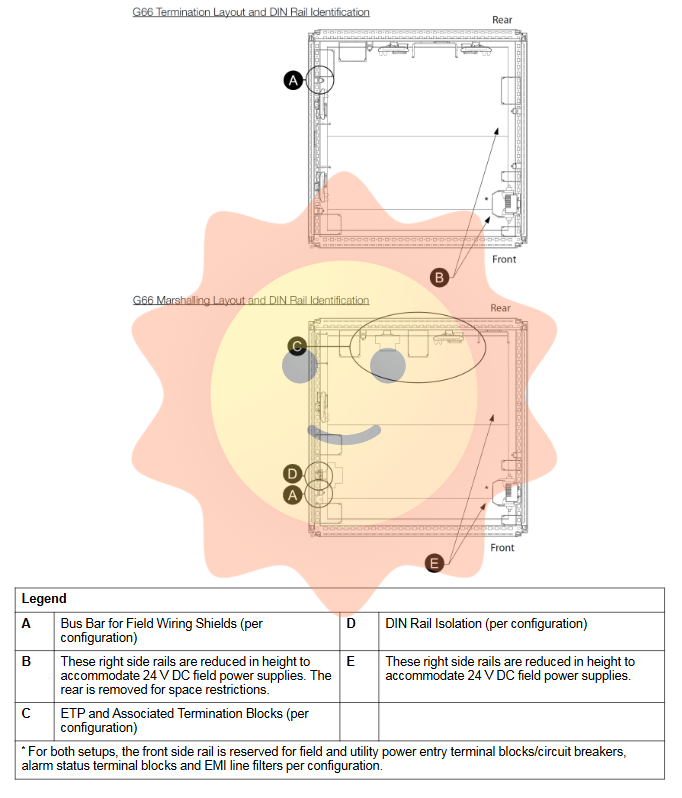

The core value of the G66 wiring cabinet lies in its specialized design for the Tricon control system. This housing can accommodate up to five vertical DIN rails, providing a total of 9.0 meters of linear track space for installing Triconex terminal components or customer provided terminal blocks. In addition, a dedicated power distribution DIN rail is reserved inside the cabinet for installing on-site power or distribution terminal block components, thereby achieving centralized power management.

This cabinet adopts a standalone or wall mounted installation design, which is particularly suitable for areas that only allow front panel access (i.e. "front only access" requirements). This design effectively shields live backend components during wiring or maintenance, greatly improving operational safety and reducing the risk of equipment damage caused by accidental contact. The cabinet base is equipped with lifting handles for easy handling and positioning, further enhancing the flexibility of on-site deployment. By utilizing third-party kits, multiple G66 cabinets can be installed side by side to maximize floor space utilization and simplify cable management for large-scale systems.

Environmental protection: IP55/66 and multi-level defense mechanism

G66 offers two distinct levels of protection for different industrial environmental conditions: normal/mild (IP43/55) and harsh (IP55/66).

IP43/55 ventilated enclosure: suitable for ordinary or mild industrial environments. This type of casing is typically equipped with a top or door mounted fan (120 V or 240 V AC, single or dual fan configuration) to provide auxiliary cooling. The fan promotes air convection and prevents components from overheating, but it increases the level of internal noise. In order to prevent solid pollutants from entering, this design utilizes the module casing and the protective layer built into the module as the basic defense. The air is exchanged between the interior of the cabinet and the external environment, but it is not strictly filtered, so it is mainly suitable for general areas with controlled air quality.

IP55/66 Sealed Shell: Designed specifically for harsh environments, providing a higher level of protection. To achieve IP55 or IP66 ratings, sealed cabinets do not rely on active air exchange (i.e. fanless). Heat is conducted to the external environment through the metal side walls and top plate of the cabinet. This means that the interior of the cabinet is an "air chamber", minimizing the risk of pollutants (such as dust and moisture) entering the interior. The sealing design is particularly suitable for places with large pollutants, corrosive gases, or requiring frequent cleaning. However, due to the lack of active airflow, users must strictly control the internal heat load, as heat can only be dissipated through external dissipation.

Advanced Protection Layer: Module Integration and "Fault Safe" Design

The safety of G66 wiring cabinet not only depends on the shell, but also on the multi-level protection architecture of its internal components. This "fail safe" concept ensures that even if the casing is slightly damaged, the core electronic equipment can remain protected.

Metal shell layer: provides the first sturdy barrier against physical impact, consisting of metal doors, top panels, and side panels.

Built in module layer: Each Triconex terminal module installed inside the cabinet comes with its own casing and protective circuit. This is the most critical internal protective layer. Even if the cabinet door is opened, the protection capability of the module is still intact, as the pollutants mainly come into contact with the module housing itself.

Thermal design and pollutant control: For sealed cabinets, heat is transferred from the internal surface to the external surface of the cabinet, and then dissipated into the factory environment. This design effectively reduces the risk of internal pollutants being drawn into the cabinet due to air exchange. Ventilation cabinets actively exhaust air through fans, which may increase noise, but their high heat dissipation capacity is more suitable for high heat load applications.

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor

- SHINKAWA