HIMA HIMax Safety Control System

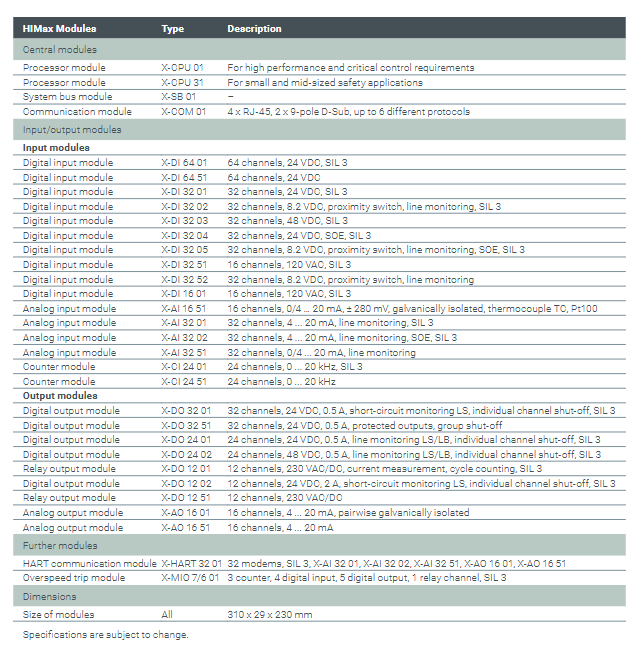

X-DI 32 51/16 01:32 channel 8.2VDC (standard type), 16 channel 120VAC (SIL 3), compatible with different types of field sensors.

Analog Input Module

Focusing on industrial standard analog signals, supporting isolation and monitoring functions:

X-AI 16 51:16 channel, supports 0/4-20mA, ± 280mV signals, galvanic isolation, compatible with thermocouples (TC) and Pt100 temperature sensors;

X-AI 32 01/02/51: 32 channels 4-20mA, Type 01 with line monitoring (SIL 3), Type 02 with line monitoring+SOE (SIL 3), Type 51 is standard.

Counter module

X-CI 24 01/51:24 channel, maximum counting frequency 20kHz, 01 type supports SIL 3, 51 type is standard, suitable for speed and pulse counting scenarios (such as encoder signal acquisition).

Digital/Relay Output Module

Emphasize safety control and fault monitoring:

X-DO 32 01/51:32 channel 24VDC/0.5A, 01 type with short circuit monitoring+single channel shutdown (SIL 3), 51 type with output protection+group shutdown;

X-DO 24 01/02:24 channels, supporting 24VDC/0.5A (line monitoring+single channel shutdown, SIL 3) and 48VDC/0.5A (line monitoring+single channel shutdown, SIL 3) respectively, SIL 3);

X-DO 12 01/51:12 channel 230VAC/DC, 01 type with current measurement+cycle counting (SIL 3), 51 type is standard type;

X-DO 12 02:12 channel 24VDC/2A, equipped with short circuit monitoring and single channel shutdown (SIL 3), suitable for high-power loads.

analog output module

X-AO 16 01/51:16 channel 4-20mA, 01 type supports paired galvanic isolation, 51 type is standard, used to control actuators such as valves and frequency converters.

Special function module

X-HART 32 01:32 HART modems, supporting cooperation with X-AI/X-AO series modules to achieve HART protocol communication (SIL 3);

X-MIO 7/6 01: Overspeed trip module, including 3 counter channels, 4 digital inputs, 5 digital outputs, and 1 relay channel (SIL 3), suitable for turbine and motor overspeed protection.

Software and Programming Support

(1) Programming Tools and Languages

Adopting the HIMA unified engineering tool SILworX, it supports multiple programming methods that comply with the IEC 61131-3 standard:

Function Block Diagram (FBD): intuitive drag and drop programming, suitable for logic control;

Sequential Function Diagram (SFC): used for sequential control scenarios (such as step flow);

Structured Text (ST): a high-level programming language suitable for complex algorithms;

C code (optional): Meets customized control requirements and requires HIMA certification.

(2) Communication Protocol and Integration Capability

The X-COM 01 communication module supports running 6 protocols simultaneously, covering security and standard communication requirements:

Safe communication: SafeEthernet (HIMA safety protocol, used for redundant communication between systems), PROFIsafe (industrial safety protocol);

Standard communication: OPC DA/A&E, Modbus TCP (master/slave), PROFINET, PROFIBUS DP (master/slave), Modbus RS485 (master/slave), TCP/UDP transceiver, SNTP (time synchronization);

Customized communication: ComUserTask (CUT), supports user programming of custom protocols (RS422/RS485 interface), HART over IP (supported by V7 version), compatible with third-party smart devices.

Compliance certification and typical applications

(1) Global Compliance Certification

The system has passed multiple international safety and industrial standard certifications, covering major global market demands:

Safety standards: IEC 61508(SIL 3)、IEC 61511(SIL 3)、EN ISO 13849-1(PL e)、EN 62061(SIL 3)、EN 50126/50129(SIL 4);

Industry standards: EN 298 (Burner Control), EN 54-2 (Fire Alarm), NFPA 72/85/86 (North American Fire and Boiler Standards), ANSI/ISA-84.00.01 (Process Safety);

Explosion proof and Environmental Protection: ATEX Zone 2(T4)、IEC Ex Zone 2(T4)、UL 508、CSA-C22.2 No.142、FM Class I Div 2、Achilles Level I( Network security);

Special fields: DNV (Maritime), Lloyd's Register (Classification Society), Russia EAC (Russian Market), ABS (Marine Equipment Certification).

(2) Typical application scenarios

Process industry: Emergency Shutdown System (ESD), Fire and Gas Monitoring System (F&G), High Voltage Protection System (HIPPS), Pipeline Management and Control (PMC);

Energy and Power: Turbomachinery Control (TMC), Boiler Protection and Burner Control System (BCS);

Transportation and infrastructure: railway level crossing control, rail vehicle safety control;

General industry: equipment interlocking, safety door control, robot protection.

Summary

The HIMax system is centered around "safety and reliability," "flexible scalability," and "full lifecycle availability." Through modular hardware, redundant architecture, multi protocol support, and comprehensive certification, it has become an ideal safety control platform for critical production processes. It not only meets strict safety standards, but also reduces downtime losses through uninterrupted operation and maintenance, online testing, and other designs, adapting to the full scenario requirements of complex systems from small and medium-sized to large. It is widely used in industries such as petrochemicals, energy, and transportation that require high safety and availability.

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor

- SHINKAWA

- Other Brands