How to install GE IC695CRU320 redundant control unit?

Product Name: Redundant Control Unit, belonging to GE Fanuc RX3i series programmable logic controllers (PLCs). Its core function is to provide dual machine redundant backup for PLC systems, ensuring seamless switching of backup controllers in case of main controller failure and avoiding system shutdown.

Document source: Product specifications and application manual published by NEX Instrument, focusing on hardware parameters, redundant logic, installation configuration, and compatibility instructions.

How to install GE IC695CRU320 redundant control unit?

Product basic information

Product model: IC695CRU320

Product Name: Redundant Control Unit, belonging to GE Fanuc RX3i series programmable logic controllers (PLCs). Its core function is to provide dual machine redundant backup for PLC systems, ensuring seamless switching of backup controllers in case of main controller failure and avoiding system shutdown.

Document source: Product specifications and application manual published by NEX Instrument, focusing on hardware parameters, redundant logic, installation configuration, and compatibility instructions.

Core functions and redundancy principles

(1) Core functions

Dual machine redundant backup

Support two RX3i controllers (such as IC695CPU315/330, etc.) to form a primary and backup architecture, and achieve hardware level redundant control through IC695CPU320.

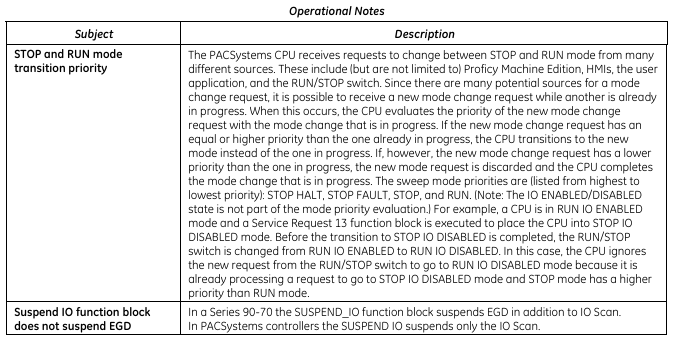

When the main controller is running normally, the backup controller synchronizes the program, data, and I/O status of the main controller in real time; When the main controller fails (such as power outage or hardware failure), the backup controller switches to the main control mode without disturbance, with a switching time of ≤ 100ms, to ensure continuous production process.

Status monitoring and diagnosis

Built in redundant status indicator lights (such as primary and backup status, synchronization status, fault alarm), visually display the operating status of the redundant system.

Support reading redundant system diagnostic information through RX3i programming software (such as Proficy Machine Edition), including switching reasons, synchronization anomalies, hardware failures, etc., for easy fault location and troubleshooting.

Flexible redundant configuration

Support the "Hot Standby" mode, where both the primary and backup controllers are powered on and running, and the backup devices are in a "ready" state instead of standby mode, improving switching speed.

Can be used with RX3i series I/O modules and communication modules, compatible with redundant I/O architectures (such as IC695RIO remote I/O modules), achieving full system redundancy coverage.

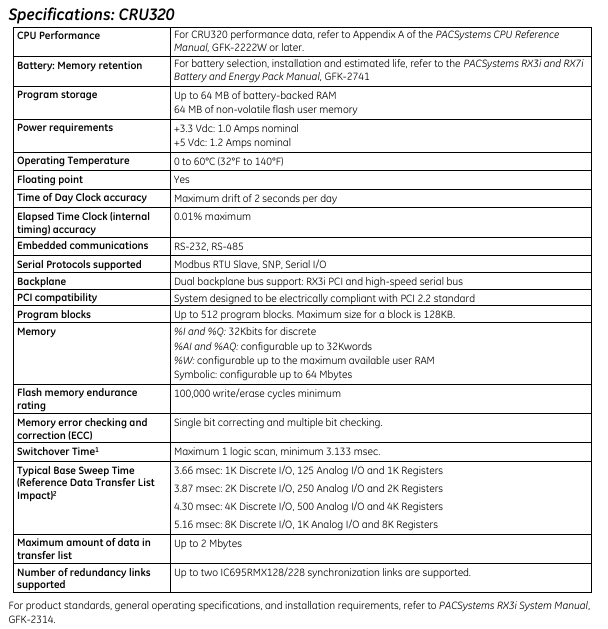

Technical specifications

(1) Hardware parameters

Specification category specific parameters

Power supply requirement input voltage:+5V DC (powered by the RX3i rack backplane, no external independent power supply required); Power consumption: ≤ 5W

Physical dimension width: 40mm (1.57 inches); Height: 100mm (3.94 inches); Depth: 160mm (6.30 inches), compatible with RX3i standard rack (such as IC695CHS012/024)

Working temperature: 0 ° C~60 ° C (operating state); -40 ° C~85 ° C (storage state)

Humidity range 5%~95% RH (non condensing, compliant with IEC 61131-2 environmental standards)

Protection level IP20 (panel installation, to be used in conjunction with control cabinet to prevent dust and liquid intrusion)

(2) Redundancy performance indicators

Performance category indicator requirements

Switching time between primary and backup: ≤ 100ms (from main controller fault detection to backup controller taking over control)

Real time data synchronization in synchronization mode (including program memory, data memory, I/O image area), with a synchronization rate of ≥ 100Mbps

Fault detection range: main controller power failure, CPU hardware failure, memory error, communication link interruption (synchronous link between main and backup)

Redundant links with built-in 2-channel high-speed synchronization interfaces (for data exchange between primary and backup controllers), supporting fiber optic or shielded twisted pair connections

Hardware composition and interfaces

(1) Hardware composition

IC695CRU320 is an independent module structure, with core components including:

Redundant control chip: responsible for determining the primary and backup status, synchronizing logic control, and triggering switching;

Synchronous communication interface: 2 RJ45 or optical ports (depending on configuration), used for data synchronization between the primary and backup controllers;

Status indicator panel: 4 LED indicator lights, meaning as follows:

RUN (green): The redundant unit is running normally;

MASTER (red): The currently connected controller is in main control mode;

STANDBY (yellow): The currently connected controller is in standby mode;

Fault (red): Redundant system failure (such as synchronization failure, module hardware error).

(2) Key interfaces

Interface Type Quantity Function Description

One rack backplane interface is inserted into the RX3i standard rack (such as IC695CHS012) and connected to the rack backplane bus to obtain power and exchange data

Two synchronous communication interfaces are connected to the main and backup controllers to achieve real-time data synchronization (supporting maximum transmission distance: 100m twisted pair cable, 2km fiber optic cable)

One reserved RS232 or Ethernet interface (some versions) for diagnostic equipment to read redundant logs

Installation and configuration requirements

(1) Installation conditions

Rack compatibility

Only compatible with RX3i series standard racks, such as IC695CHS012 (12 slots) and IC695CHS024 (24 slots), which need to be installed in the "redundant control unit dedicated slot" of the rack (usually slots 1-2 on the left side of the rack, refer to the rack manual for details).

Controller compatibility

The primary and backup controllers must be RX3i CPU modules of the same model, supporting models including IC695CPU315, IC695CPU330, IC695CPU340, and the CPU firmware version must be consistent (recommended V3.0 and above).

Environmental Requirements

The installation environment should be kept away from strong electromagnetic interference (such as frequency converters, high-power motors), and avoid sudden temperature changes or dusty/humid environments;

Reserve a heat dissipation space of ≥ 50mm around the module to ensure good heat dissipation (without forced air cooling, the ambient temperature does not exceed 55 ° C).

(2) Configuration steps

Hardware Installation

Insert IC695CRU320 into the dedicated slot of RX3i rack and tighten the panel screws;

Connect the synchronization interface between IC695CRU320 and the main and backup controllers using a synchronous cable (twisted pair or fiber optic);

Connect the power supply, I/O module, and communication module separately for the primary and backup controllers (ensuring consistent configuration of primary and backup I/O).

Software configuration (via Proficy Machine Edition)

Create a new RX3i redundancy project, select the "dual machine redundancy" architecture, specify the primary and backup CPU models and IC695CRU320 as redundant control units;

Configure synchronization parameters (such as synchronization rate, timeout) to enable the "automatic switching" function;

Download the program to the main controller, and the software will automatically trigger the synchronization of primary and backup data. After the synchronization is completed, the redundant system will enter the "normal operation" state.

Compatibility and selection suggestions

(1) List of compatible hardware

Example of compatible device types and models

RX3i Controller IC695CPU315 (Compact), IC695CPU330 (Standard), IC695CPU340 (High Performance)

RX3i rack IC695CHS012 (12 slots), IC695CHS024 (24 slots), IC695CHS008 (8 slots, small system)

Redundant I/O modules IC695RIO001 (remote I/O adapter), IC695RIO002 (redundant I/O interface module)

Communication modules IC695ETM001 (Ethernet module), IC695COM001 (RS485 module)

(2) Selection suggestions

Applicable scenarios

Industrial scenarios that require continuous operation, such as chemical production lines, power dispatch systems, water treatment equipment, etc., require a system availability requirement of ≥ 99.99%.

Selection precautions

The primary and backup controllers need to be completely consistent (model, firmware version, memory configuration) to avoid synchronization failure due to hardware differences;

If the system includes remote I/O, redundant I/O modules (such as IC695RIO002) should be used to ensure that the I/O layer also has redundancy capability;

It is recommended to use shielded twisted pair cables (short distance, ≤ 100m) or multimode optical fibers (long distance, ≤ 2km) for synchronous cables to reduce synchronization anomalies caused by interference.

Troubleshooting and Maintenance

(1) Common faults and solutions

Possible causes and solutions for the fault phenomenon

The redundant status light "FAULT" is always on. 1. The synchronization link between the primary and backup controllers is interrupted; 2. The firmware versions of the primary and backup CPUs are inconsistent; 3. CRU module hardware failure: 1. Check the synchronization cable connection and replace the faulty cable; 2. Upgrade the primary and backup CPUs to the same firmware version; 3. Replace the IC695CRU320 module

Primary/backup switching failure: 1. Backup controller data synchronization is not completed; 2. The switch enable is not turned on; 3. Inconsistent I/O configuration: 1. Wait for synchronization to complete (the synchronization light is always on to indicate completion); 2. Enable "automatic switching" in the software; 3. Verify the primary and backup I/O configurations to ensure consistency

The backup controller cannot synchronize. 1. Poor contact of the synchronization interface; 2. Memory error in the main controller; 3. CRU synchronization logic fault 1. Re plug and unplug the synchronization cable, clean the interface; 2. Restart the main controller and check the memory status; 3. Reset CRU module (via software or power off restart)

(2) Daily maintenance suggestions

Regularly (every 3 months) check the redundancy status indicator lights to confirm that the primary and backup are running normally and the synchronization link is normal;

Export redundant system diagnostic logs through Proficy Machine Edition every 6 months to analyze potential risks such as frequent synchronization failures and switching records;

Avoid plugging and unplugging CRU modules or synchronous cables while they are live to prevent hardware damage; When replacing modules, power off first to ensure that the primary and backup controllers are in a "stop" state.

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor

- SHINKAWA

- Other Brands