Kollmorgen H series brushless servo motor and Silverline driver

Kollmorgen H series brushless servo motor and Silverline driver

Introduction

In the field of modern industrial automation and motion control, the performance, reliability, and cost-effectiveness of servo systems are key factors determining equipment competitiveness. As a leading global supplier of motion control systems, Kollmorgen's Silverline product line has always been renowned for its high cost-effectiveness, high performance, and ease of integration. This article is based on the official product manual "Silverline Motor Catalog" of Kollmorgen, providing a comprehensive and in-depth technical analysis of its H-series brushless servo motor and matching Silverline series drive. The aim is to provide a detailed reference guide for engineers, system integrators, and procurement decision-makers.

Product Overview: H Series Brushless Servo Motor

The H series is a low-cost, high-performance brushless servo motor designed by Kollmorgen to replace traditional stepper motors and improve system performance. The core design concept is to achieve superior dynamic response, accuracy, and efficiency through servo technology without sacrificing reliability.

1.1 Core Features and Advantages

Mechanical compatibility: The motor frame size (2.3 "to 3.43" square) is fully compatible with the installation holes of NEMA 23 and NEMA 34 standard stepper motors, allowing existing devices using stepper motors to seamlessly upgrade to servo systems without changing the mechanical structure.

Wide torque range: Continuous stall torque covers 58.8 oz in to 786 oz in (0.4 N-m to 5.5 N-m), with higher peak torque, meeting diverse application needs from light load positioning to heavy load driving.

High performance rotor: Using high-energy rare earth permanent magnet materials, low rotor inertia is achieved, resulting in extremely high acceleration and deceleration, shortened setting time, and improved equipment cycle time.

Flexible feedback options: Hall effect sensors are standard for commutation, while encoders are available as optional configurations to meet the needs of closed-loop position or speed control.

Protection level: With an IP-40 sealing level, it provides basic dust protection and is suitable for common industrial environments.

1.2 Product Family and Model Naming

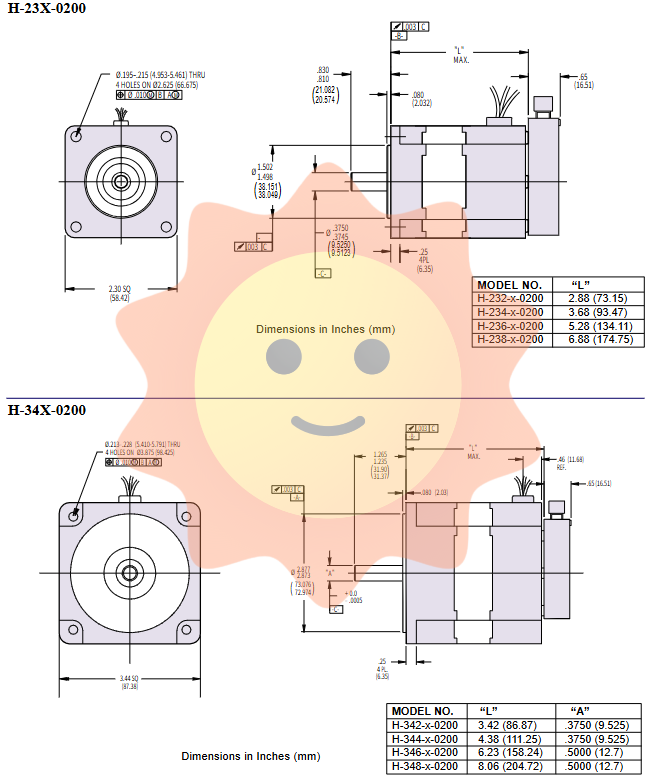

The H series motors are mainly divided into two sub series, corresponding to different frame sizes:

H-23X series: Corresponding to NEMA 23 size, the motor body is more compact.

H-34X series: Corresponding to NEMA 34 size, providing higher torque and power.

The naming convention for models is usually shown as "H-344-H-0200", where:

H: Series code.

3: Machine base size (3 represents a 3.4-inch frame, i.e. NEMA 34).

44: Code for the length of motor laminations, representing different iron core lengths and torque levels.

H: Winding code, representing specific electrical parameters such as voltage constant and torque constant.

0200: Feedback type code (e.g. 0200 represents standard Hall, 0600/0802 represents with different types of encoders).

Detailed technical specifications and performance parameters

The manual provides an extremely detailed parameter table, which is the core basis for motor selection. The key parameter analysis is as follows:

2.1 Electrical and Torque Performance (Taking H-34X Partial Models as Examples)

Model: Continuous stall torque (Tc), peak torque (Tp), continuous power, rated maximum speed, continuous current (Ic), peak current (Ip), torque constant (Kt), back electromotive force constant (Kb)

H-342-H 179 oz-in (1.26 N-m) 375 oz-in (2.65 N-m) 0.63 HP (470 W) 6000 RPM 12.0 A DC 28.0 A DC 14.9 oz-in/A DC 12.5 V-O-PK/KRPM

H-344-H 297 oz-in (2.10 N-m) 745 oz-in (5.26 N-m) 0.94 HP (701 W) 4050 RPM 11.7 A DC 32.6 A DC 25.4 oz-in/A DC 21.3 V-O-PK/KRPM

H-348-H 745 oz-in (5.26 N-m) 2012 oz-in (14.21 N-m) 1.10 HP (821 W) 1850 RPM 11.5 A DC 34.5 A DC 64.7 oz-in/A DC 54.3 V-O-PK/KRPM

Parameter interpretation:

Continuous and peak torque: Continuous torque determines the long-term stable operation ability of the motor, while peak torque determines the short-term overload and acceleration ability. When selecting, it is necessary to ensure that the maximum load torque applied is lower than the continuous torque, and the dynamic peak load is lower than the motor peak torque.

Torque constant (Kt): The torque generated per unit current is an important indicator for evaluating the efficiency of a motor. The higher the Kt value, the smaller the current required to generate the same torque, and the lower the copper loss of the winding.

Back electromotive force constant (Kb): The proportional relationship between the back electromotive force generated during motor rotation and the rotational speed. During high-speed operation, the back electromotive force will offset some of the power supply voltage, so Kb and the power supply voltage jointly determine the maximum theoretical speed of the motor.

2.2 Mechanical and Thermal Properties

The rotor inertia (Jm): H-342-H is 0.00679 oz-in-s ². Low inertia is the foundation for achieving rapid response. The matching of load inertia and motor rotor inertia (usually recommended ratio within 10:1) is crucial for system stability.

Thermal parameters: including thermal time constant and thermal resistance. For example, the thermal resistance of H-344-H is 1.6 ° C/W. The smaller this value, the stronger the motor's heat dissipation ability and the higher the sustainable output torque.

Theoretical acceleration: calculated by dividing the peak torque by the rotor inertia, reflecting the maximum dynamic capability of the motor body. The theoretical acceleration of H-342-H reaches 255300 rad/s ².

2.3 Important Selection Annotations

The manual emphasizes the parameter conversion when matching with the driver:

When using a sine wave driver, the Kt of the six step commutation (trapezoidal wave) needs to be multiplied by 1.2828 to obtain the torque constant based on RMS current; Divide Kb by 1.414 to obtain the back electromotive force constant based on RMS voltage.

The maximum speed is limited by the lowest value among electrical limits, mechanical structure, feedback devices, and bearings. The motor must be used in conjunction with a driver with overspeed protection function.

The performance curve is usually drawn based on an ambient temperature of 40 ° C, and in practical applications, heat dissipation conditions need to be considered.

Mechanical interface and installation dimensions

The manual provides detailed dimension drawings, covering models with different feedback options (0200, 0600, 0802, etc.).

Installation flange: Fully compatible with NEMA standards, easy to install.

Shaft extension specifications: The H-23X series typically offers a 0.250 "shaft diameter; in the H-34X series, the H-342/H-344 has a 0.375" shaft diameter, and the H-346/H-348 has a 0.500 "shaft diameter.

Axle load: The allowable axle load curve calculated based on a 20000 hour L10 life is provided on page 11 of the manual. The distance between the application point of radial load and the installation surface is clearly specified (0.75 "for H-23X and 1.0" for H-34X), and the selection must ensure that the actual load is within the curve range.

Detailed explanation of supporting drivers

One of the advantages of Silverline servo system is its highly matched and economically efficient matching driver family.

4.1 SO/RO/OL series amplifiers

This is a type of compact driver that focuses on providing high-performance current loops.

Product positioning: Economical and efficient, suitable for cost sensitive applications.

Model differentiation:

SO series: Low voltage DC input (20-40 VDC), suitable for battery powered or low-voltage applications.

RO series: High voltage DC input (135-190 VDC).

ROL series: AC input (90-130 VAC), built-in rectifier, the most convenient to use.

Working mode (selected through jumper):

Current loop mode: With a bandwidth>2500 Hz and extremely fast response, it is the preferred choice for achieving precise position control in conjunction with upper level motion controllers.

Open loop mode: used in situations where speed accuracy is not required.

Encoder speed loop mode (ROL only): Convert the motor encoder feedback into an analog speed signal for closed-loop speed regulation.

Speed loop mode of speedometer (ROL only): external analog speedometer for speed control.

Key features: Four quadrant regeneration operation, comprehensive protection function (overcurrent, overvoltage, overheating, short circuit), built-in heat sink, six step commutation, optically isolated I/O.

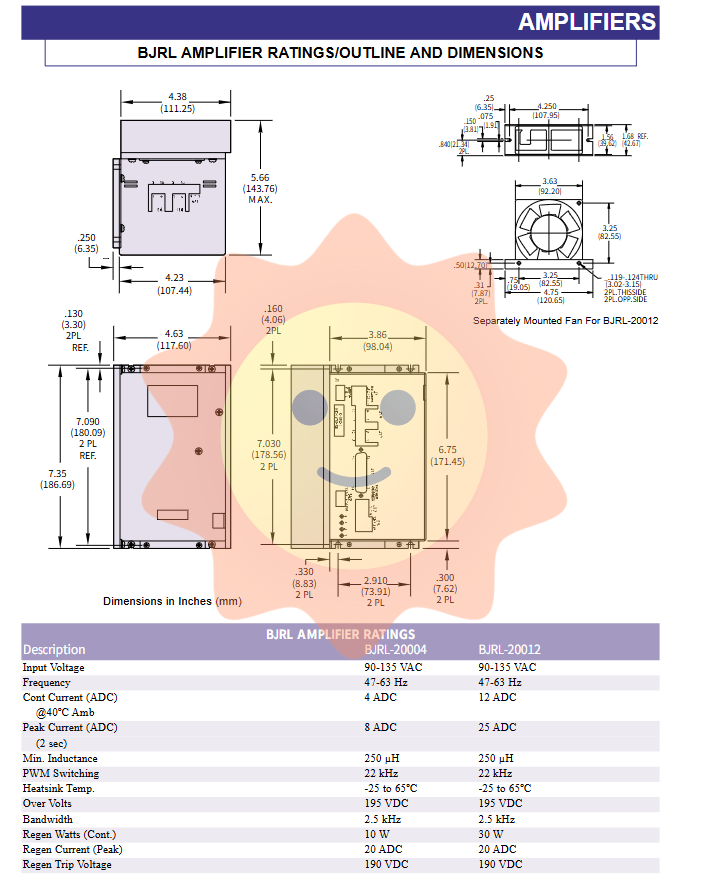

4.2 BJR/BJRL Series Amplifier/Positioner

This is a highly integrated "all-in-one" solution that combines an amplifier with a motion controller.

Core features:

Built in motion control: Using the BASIC like BDS5 programming language, complex functions such as point-to-point positioning, electronic gears, and electronic camshafts can be completed without the need to purchase additional motion control cards.

Rich I/O: Provides 14 digital inputs, 6 digital outputs, 3 analog inputs, and 1 analog output, making it easy to directly connect sensors and actuators.

Communication interface: Standard RS-232 and RS-485, supporting multi station networks.

Model differentiation: BJR is DC input, BJRL is AC input.

Applicable scenarios: Very suitable for single axis or simple multi axis independent automation equipment, such as feeders, indexing tables, small assembly machines, etc., which can significantly reduce system complexity and total cost.

4.3 SPS power module

Specially designed for SO amplifiers, it can convert single-phase AC power (115/230 VAC optional) to DC bus voltage and can power up to 4 SO amplifiers, with optional regenerative resistors.

System Matching and Selection Guide

The "Compatibility Matrix" on page 12 of the manual is the core tool for selection. It specifies the recommended driver model for each motor to ensure performance and safety margin.

For example:

The H-342-H motor can be paired with RO (L) -20004, BJR-20004, or BJR-20012 drivers.

When making a choice, it is necessary to consider comprehensively:

Voltage matching: The required bus voltage is determined by the back electromotive force and speed requirements of the motor, and the input voltage of the driver must meet them.

Current matching: The continuous current and peak current of the motor must be less than the continuous output current and peak (overload) output current of the driver.

Control requirements: When an external motion controller (such as PLC, motion control card) is needed, select the SO/RO/OL series; When an integrated solution is needed, choose the BJR/BJRL series.

Feedback matching: Motors with encoders need to be used in conjunction with drivers that support encoder feedback, such as the speed loop mode of ROL or the position loop mode of BJR.

Application scenarios and competitive advantages

Stepper motor replacement: Upgrades can be made to existing equipment that uses stepper motors, without the need to modify the machinery, to achieve high response, high precision, strong overload capacity, and low-speed stability of servo systems, especially suitable for situations where there is a risk of step loss or where higher dynamic performance is required.

Cost sensitive OEM equipment: The Silverline series offers servo system performance at a cost close to that of a stepper system, providing highly competitive core moving parts options for equipment manufacturers in packaging, printing, textile, semiconductor handling, small CNC machine tools, and other fields.

Multi axis distributed control: The BJR/BJRL locator can be networked through RS-485 to build a low-cost, distributed multi axis control system, reducing the burden on the central controller.

Installation and usage precautions

Wiring: Strictly follow the sensor wiring diagram (page 9) in the manual to connect the Hall sensor or encoder, ensuring correct phase sequence, otherwise it may cause abnormal motor operation or damage.

Heat dissipation: Ensure that the drive is installed in a well ventilated environment and leave sufficient heat dissipation space. The motor needs to reduce torque appropriately when used in high temperature environments.

Protection: The system must be equipped with appropriate circuit breakers or fuses. Ensure good grounding when using communication input drivers.

Debugging: When using BJR/BJRL, its self-tuning function can be used to optimize servo gain. For SO/RO/OL, it is necessary to set the current loop and position loop parameters reasonably in the upper controller.

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor

- SHINKAWA

- Other Brands