Kollmorgen Servo System Product Guide

Kollmorgen servo system: leading integrated motion control with high precision and dynamic performance

In the fields of industrial automation and precision machinery, the performance of motion control systems directly determines the output quality, efficiency, and reliability of equipment. Kollmorgen, as a motion control expert under the Danaher Group, has built a complete, efficient, and highly integrated servo system product ecosystem with decades of technological accumulation and innovation. This article aims to provide an in-depth analysis of Colemorgen's core product line, including its iconic AKD series servo drives, AKM series servo motors, innovative direct drive technology, and diverse linear positioning and transmission solutions, demonstrating how it integrates technology to "clear design, procurement, and time barriers" for OEM manufacturers.

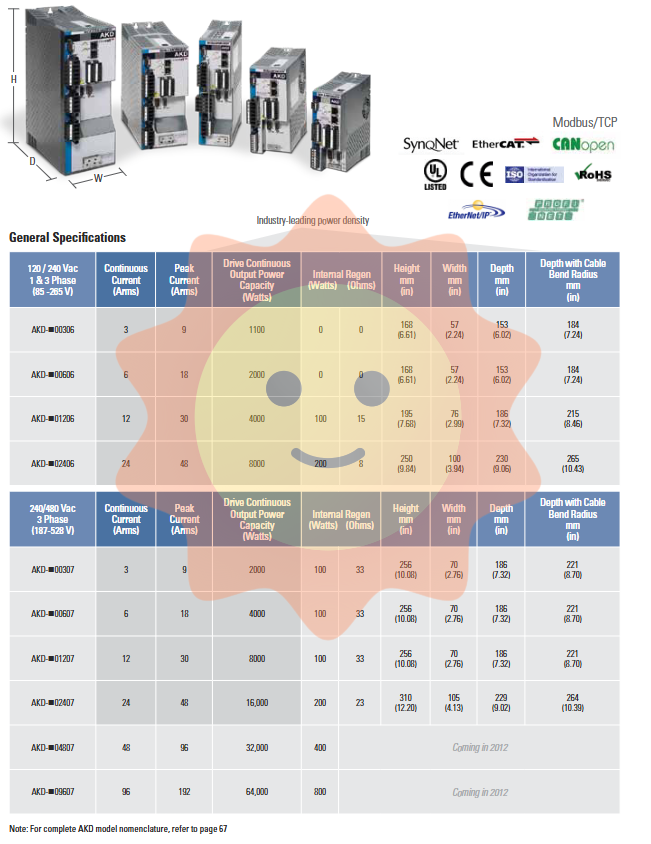

Core power: AKD series servo drive - high-performance control center based on Ethernet

The Kolmorgen AKD series servo drives represent the advanced level of servo drive technology today. It is not just a power amplifier, but also an intelligent control node that integrates advanced control algorithms, rich communication options, and programmable functions.

1. Excellent performance and technical features:

The core advantage of AKD drivers lies in their "second level optimization" performance. The performance servo tuner (PST) with pending patent has industry-leading automatic tuning capability, which can automatically adjust all gain parameters including the observer and respond in real-time to dynamic load changes. It can handle inertia mismatches of up to 1000:1 and accurately compensate for rigid and flexible transmission mechanisms, ensuring the system maintains optimal performance under a wide range of operating conditions.

The driver adopts a powerful dual processor system and runs leading servo algorithms, achieving extremely high bandwidth and extremely fast digital current loop response. It supports feedback devices with up to 27 bit resolution, providing unparalleled position accuracy and repeatability. Whether it is a single/multi turn absolute value encoder (such as EnDat2.2, BiSS, HIPERFACE) ®), Whether it is a rotary transformer or an incremental encoder, AKD can be seamlessly compatible and achieve plug and play with Colmorgen motors through electronic motor nameplate function, greatly reducing debugging time.

2. Flexible architecture and scalability:

The AKD series provides a wide range of power coverage from 3A to 48A (peak current) with its compact packaging, and has extremely high power density. Its true flexibility is reflected in its scalable programmability and communication integration. From basic analog torque/speed control ("B" selection), to simple point-to-point indexing ("P" selection), to 1.5-axis drivers that support BASIC programming ("T" selection), to multi axis main control drivers with complete soft PLC functionality (such as AKD PDMM), AKD provides a smooth upgrade path.

At the communication level, AKD natively integrates multiple mainstream industrial Ethernet and fieldbus, including EtherCAT ®, SynqNet ®, Modbus/TCP, EtherNet/IP, PROFINET, And CANopen ®, No additional hardware tabs are required, simplifying system integration and reducing costs.

3. Humanized development and debugging tools:

The Kollmorgen WorkBench graphical user interface (GUI) greatly simplifies the process of setting up, debugging, and diagnosing drivers. Its built-in six channel real-time software oscilloscope, multifunctional Bode plot, and one click parameter sharing function enable engineers to quickly evaluate performance, diagnose problems, and collaborate for communication. This application-oriented design concept significantly reduces the threshold for use and improves development efficiency.

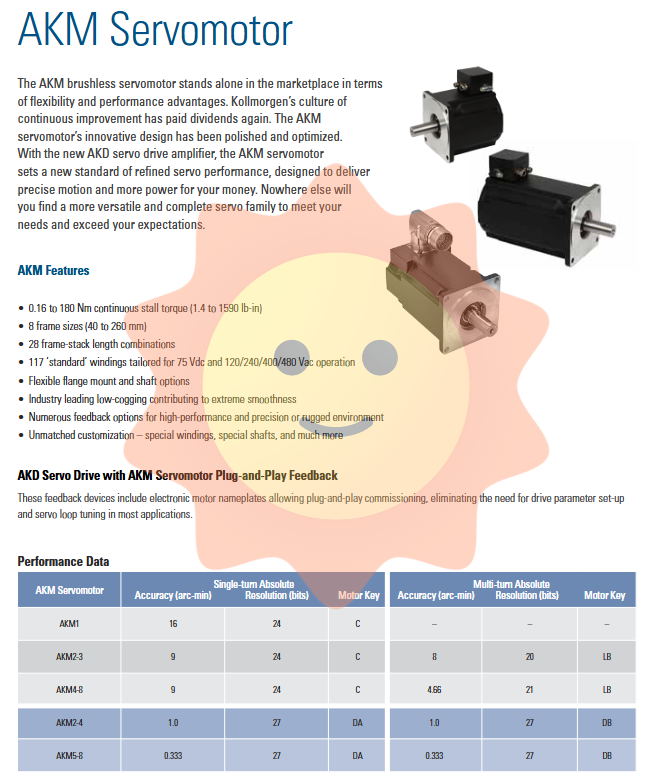

Accurate execution: AKM series servo motors - the source of power that combines breadth and depth

AKM frameless servo motors are the backbone of Kohlmorgen's product portfolio, renowned for their unparalleled flexibility, high power density, and outstanding performance.

1. Extensive configuration and optimized design:

The AKM series covers 8 machine base sizes from NEMA 17 (40mm) to NEMA 42 (180mm), offering up to 28 body stack combinations and nearly 120 standard windings. Its continuous locked rotor torque range extends from 0.16 Nm to 180 Nm, which can meet diverse needs from micro automation equipment to heavy industrial machinery. Through continuous optimization of the magnetic circuit and cooling system, the new generation AKM motor can provide up to 47% shaft power increase with the same base size when paired with AKD drives, while reducing the size of the drive and motor and lowering the overall system cost.

2. Support high-performance and high reliability applications:

AKM motors offer a wide range of feedback options, from high-resolution sine encoders to cost-effective intelligent feedback devices (SFDs), meeting different precision and cost requirements. The newly launched IP67 protection level option enables it to confidently be applied in harsh industrial environments such as humidity and dust. The motor itself has extremely low cogging torque, ensuring smooth low-speed operation, which is crucial for precision machining, printing, and inspection applications.

Subverting tradition: Direct Drive Technology (DDT) - achieving ultimate accuracy and dynamic response

In order to overcome the precision, bandwidth, and maintenance bottlenecks caused by traditional mechanical transmissions (gearboxes, belts, couplings, etc.), Colemorgen provides a comprehensive direct drive solution.

1. Directly drive the rotating motor:

Kohlmorgen's direct drive rotary motors are divided into three categories: Cartridge DDR, Housed DDR, and Frameless DDR, which meet different integration requirements.

Cartridge DDR: Revolutionary combination of the space saving advantages of frameless motors and the easy installation features of framed motors. It uses the machine's own bearings to support the rotor and connects the load through an innovative compression coupling. Its torque density can be 50% higher than traditional servo motors of the same size, and it integrates a high-resolution sine encoder (134217728 counts/rev) with a repeatability accuracy of better than 1 arcsecond and an absolute accuracy of ± 26 arcseconds, far superior to precision planetary gearboxes (usually with 1-2 arcminutes backlash). In applications such as feeders, it replaces the motor+reducer+belt drive system, reducing assembly time from hours to 5 minutes, significantly reducing the number of parts, increasing throughput by up to 100%, and achieving zero maintenance.

Housed DDR: Comes with bearings and encoders to form a complete rotating component, making it ideal as the core drive for turntables or indexing plates. Its high stiffness, zero backlash, and excellent dynamic performance make it outstanding in medical manufacturing and semiconductor equipment, significantly reducing audible noise and supporting flexible electronic cam and electronic gear functions.

2. Directly drive linear motor:

Directly driving a linear motor eliminates intermediate transmission links such as ball screws and gear racks, and applies power directly to the load. This brings infinite travel possibilities, zero backlash, ultra-high acceleration, extremely smooth speed control, and almost zero maintenance requirements. Colemorgen offers hundreds of customized and semi customized linear motor solutions, with a thrust of up to 15.6 kN and precision of micrometer level, making it an ideal choice for high-speed and high-precision laser processing, electronic assembly, and testing equipment.

Precision Transmission and Positioning: Modular Mechanical Components

For applications that still require mechanical transmission, Colemorgen offers a range of high-performance, modular positioning and transmission components.

1. Precision positioning table (DS4/DS6 series):

The DS series positioning station is an ideal module for building high-precision single axis or multi axis (XY, XYZ) systems. They use high-quality ball screws, linear guides, and unique IDEAL-SEAL magnetic seal technology to effectively protect the internal structure. We offer two precision levels: commercial grade and precision grade, with a bidirectional repeat positioning accuracy of ± 1.3 microns (precision grade). Rich options, such as motor installation direction (direct or parallel), coupling type, limit/origin sensor, and linear grating ruler, allow users to deeply customize.

2. Electric cylinder and rodless actuator:

Electric cylinder (N2/EC series): As a clean and efficient alternative to hydraulic and pneumatic cylinders, electric cylinders provide precise thrust control and position control. The EC series complies with the ISO 6431 standard, with a thrust range from 667 N to 25000 N and a maximum speed of 1.33 m/s. It comes standard with IP54 protection (optional IP65). They are suitable for linear pressing, lifting, and valve control applications that require high thrust.

Rod free actuator (R series): Integrated with linear bearings, it can provide thrust while supporting and guiding loads. The R series offers options for ball screw, lead screw, or synchronous belt transmission, with a travel of up to 2.7 meters and a maximum speed of 3 m/s (with transmission). Its compact cross-sectional design makes it an efficient component for building Cartesian coordinate robots.

3. Micron ™ TRUE Planetary ™ Reducer:

Using unique spiral crown gear technology, compared to traditional spur gear planetary reducers, it has a higher contact ratio, bringing higher torque capacity, better load sharing, lower backlash (up to 4 arcminutes), and almost "whisper" level quiet operation. RediMount ™ The system simplifies the installation and docking with servo motors, ensuring error free assembly. In addition, PowerTrue is used ™ The right angle reducer with face gear technology achieves a single-stage transmission ratio of up to 5:1 and an efficiency of 98%, with a very compact structure.

From Components to Systems: Integrated Control and Customized Solutions

The core competitiveness of Colemorgen lies in its ability to provide solutions rather than just system integration of components.

1. Kollmorgen Automation Suite ™:

This is a unified and scalable automation development kit that covers programming, configuration, and debugging from single axis drives to PAC based 128 axis complex motion control systems. It supports all five IEC 61131-3 programming languages (including ladder diagrams, structured text, etc.) as well as PLCopen motion control function blocks. Its innovative Pipe Network ™ The programming approach allows engineers to describe complex multi axis coordinated movements (such as electronic camshafts and flying shears) in intuitive data flow form, greatly simplifying the development of advanced applications.

2. Customized engineering capability:

Colemorgen has a strong culture of 'common engineering'. Whether it's modifications based on massive standard products (such as special shaft extensions, feedback, connectors, or environmental protection), or fully customized designs from scratch (suitable for extreme environments such as medical implants, aerospace, deep-sea equipment, etc.), its cross functional team can provide support. The company has motor design capabilities ranging from 0.5 Nm to 29000 Nm and experience in developing drivers/controllers from single axis to multi axis, ensuring that products meet strict industry certification requirements such as UL and CE. This "optimization solution" process, combined with rapid prototyping capabilities, helps customers significantly shorten product launch time and reduce project risks.

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor

- SHINKAWA

- Other Brands