Horner Automation MAN0344-03 Industrial Controller/Human Machine Interface (HMI)

Safety Warning: Contains core safety regulations for industrial equipment operation, such as electrical safety (grounding requirements, voltage range, anti electric shock warning), installation safety (layout inside the control cabinet, heat dissipation space, anti vibration measures), operational safety (prohibiting live module plugging and unplugging, emergency shutdown process in case of fault), and labeled with compliant safety standards (such as UL, CE, CSA).

Horner Automation MAN0344-03 Industrial Controller/Human Machine Interface (HMI)

Product Overview and Safety Specifications

Product Introduction: Clarify the specific product models that the manual is compatible with (such as XL4, HE4, etc. Horner controllers), introduce the core functions of the product (such as logic control, HMI display, multi protocol communication, I/O expansion), application scenarios (single machine control, small distributed systems), and hardware appearance (panel layout, interface position, indicator light definition).

Safety Warning: Contains core safety regulations for industrial equipment operation, such as electrical safety (grounding requirements, voltage range, anti electric shock warning), installation safety (layout inside the control cabinet, heat dissipation space, anti vibration measures), operational safety (prohibiting live module plugging and unplugging, emergency shutdown process in case of fault), and labeled with compliant safety standards (such as UL, CE, CSA).

Hardware Installation and Wiring Guide

Installation process: Detailed description of the physical installation steps of the product, including DIN rail installation (compatible with industrial control cabinet standards), fixing method (screw specifications, torque requirements), installation environment requirements (working temperature -10 ℃~+60 ℃, humidity 5%~95% RH, no condensation, protection level IP20/IP65 depending on product model).

Wiring specifications:

Power wiring: Clearly define the DC/AC power supply range (such as 24V DC ± 10%, 100-240V AC), distinguish between positive and negative poles, and recommend the power line diameter (such as 1.5mm ²);

I/O wiring: Terminal definitions for digital input/output (DI/DO) and analog input/output (AI/AO), wiring sequence (such as DI signal positive and negative poles, AO load resistance range), and wiring examples for common sensors/actuators (such as proximity switches and frequency converters);

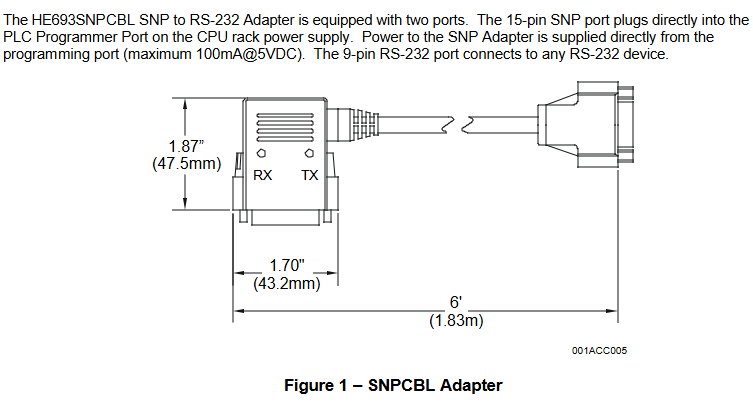

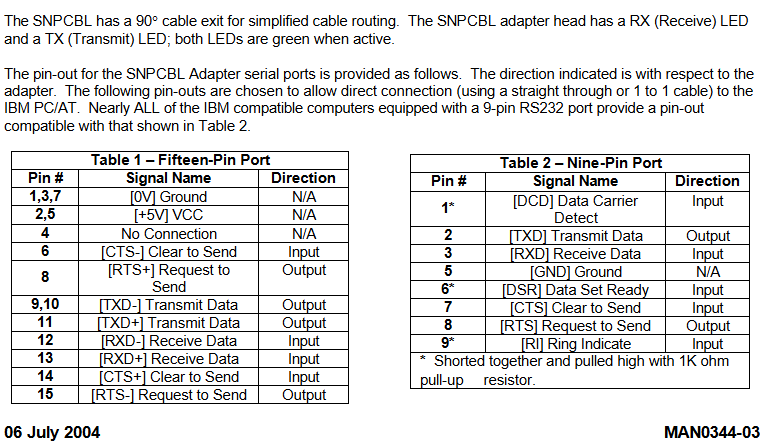

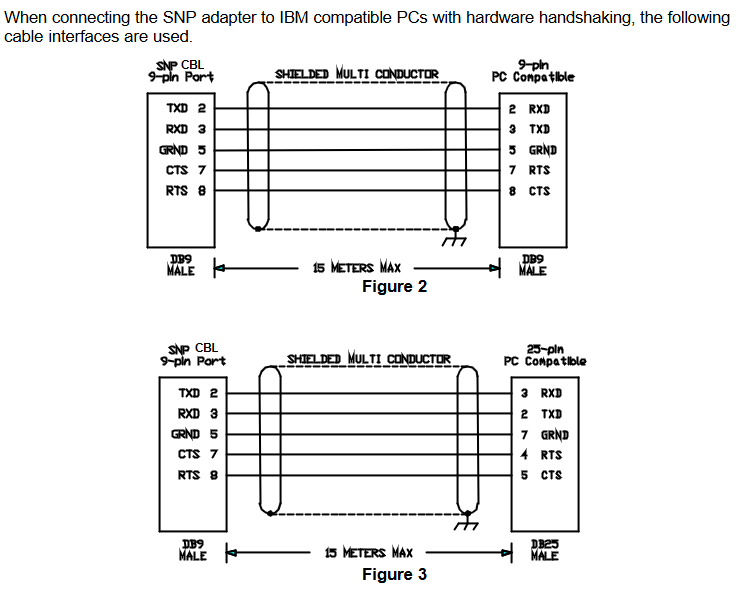

Communication wiring: Pin definitions, cable selection (such as shielded twisted pair), anti-interference wiring measures (such as terminal resistance matching) for communication interfaces such as Ethernet (RJ45), RS485/RS232 serial port, CAN bus, etc.

Software configuration and programming operations

Software Tool Introduction: Specify Horner specific programming and configuration software (such as Cscape) ®), Explain software installation requirements (operating system version, hardware configuration), software interface functional zoning (project management, ladder diagram programming, HMI screen editing, device communication configuration).

Basic configuration process:

Device connection: Establish communication with the computer through USB/Ethernet to complete device identification and firmware version detection;

Parameter settings: configuration steps for system parameters (clock, language, backlight brightness), I/O parameters (analog range calibration, digital filtering frequency), and communication parameters (IP address, baud rate, parity);

Programming: Basic operations of supported programming languages (ladder diagram LD, functional block diagram FBD, structured text ST), writing and downloading process of example programs (such as motor start stop control, temperature acquisition display).

HMI screen design: Guide users to create a visual operating interface, including adding controls (buttons, indicator lights, numerical displays, trend charts), associating variables (binding with controller I/O points or internal registers), and setting permissions (distinguishing operator/administrator permissions to prevent misoperation).

Daily operation and maintenance

Operation guide: Equipment power on start-up process (self checking steps, fault light meaning), daily operation (parameter monitoring, manual/automatic mode switching, alarm confirmation), data recording and querying (historical fault records, production data export).

Maintenance suggestion:

Regular maintenance: cleaning (panel wiping, cooling fan dust removal), wiring inspection (terminal tightening, cable aging detection), firmware upgrade (online software updates to ensure functional compatibility);

Consumables replacement: Steps and precautions for replacing backlight modules and backup batteries (powered by real-time clock).

Troubleshooting and technical support

Fault diagnosis method:

Indicator light troubleshooting: Comparison table of status meanings of panel LED lights (power light, communication light, fault light) (such as red light constantly on=power failure, flashing=communication abnormality);

Software diagnosis: Use Cscape software to read internal fault codes of the device (such as E001=I/O short circuit, E010=communication timeout), and provide the corresponding fault causes and solutions for the codes.

Frequently Asked Questions (FAQ): A step-by-step troubleshooting process for high-frequency issues such as device communication failure, HMI screen not displaying, and analog data acquisition deviation. Example: "Communication failure → Check cable → Confirm IP address → Restart device → Reconnect".

Technical support information: Horner Automation global service hotline, regional agent contact information, official website technical resource library (manual download, firmware update, video tutorial) address, and product warranty information (warranty period, warranty scope).

Usage recommendations

Product adaptation confirmation: Before use, it is necessary to check the cover of the manual or the "Applicable Products" section to confirm whether it matches the actual model of the Horner controller used (such as XL4e, HE8), in order to avoid operational errors caused by model differences.

Safety priority: Strictly follow the requirements of the "Safety Regulations" chapter, especially the warnings related to high-voltage wiring and live operation. If necessary, installation should be completed by personnel with electrician qualifications.

Combining software practice: It is recommended to operate Cscape software while reading the manual during the configuration and programming process. After familiarizing oneself with the process through example programs, write the actual control program to reduce the probability of errors.

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor

- SHINKAWA

- Other Brands