Siemens MOBY I RFID System Configuration and Application Guide

Siemens MOBY I RFID System: A High Performance Non Contact Identification Solution for Industrial Automation

Introduction

In modern industrial production and logistics processes, reliable, fast, and non-contact identification and data tracking of objects have become key to improving efficiency and flexibility. The Siemens MOBY I wireless radio frequency identification (RFID) system is a high-performance solution designed for such high-end application scenarios. This system integrates features such as large capacity data storage, long-distance read and write capabilities, and high-speed data transmission, specifically designed to optimize material flow and production processes. This article will delve into the technical architecture, core components, configuration points, and installation guidelines of the MOBY I system, providing a complete set of application references for engineers and technicians.

System Overview and Technical Features

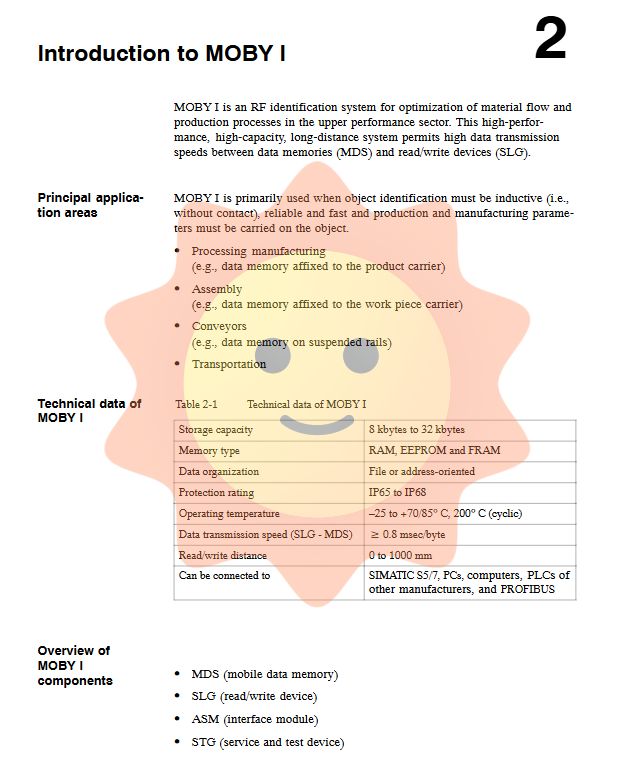

MOBY I is an identification system operating in the radio frequency (RF) band, with its core advantages being high capacity, long distance, and high transmission speed. The system has a storage capacity ranging from 8KB to 32KB, supporting multiple types of memory such as RAM, EEPROM, and FRAM. Data organization can be file oriented or address oriented. The read and write distance can reach up to 1000 millimeters (in conjunction with SLG 44 and MDS 507), with a data transmission rate of up to 19200 baud and a processing time of as short as 0.8 milliseconds per byte.

The system has a wide operating temperature range, and standard components can operate stably in environments ranging from -25 ° C to+70/85 ° C. The specially designed high-temperature resistant model MDS 439E can even withstand cyclic operating temperatures up to 200 ° C. All components have a protection level of IP65 to IP68, with excellent dust and water resistance, and can adapt to harsh industrial environments.

MOBY I has excellent compatibility and can seamlessly connect to Siemens SIMATIC S5/S7 series programmable logic controllers (PLCs), personal computers, other manufacturers' PLCs, and PROFIBUS fieldbus networks, making it easy to integrate into existing automation architectures.

Detailed explanation of core components

The MOBY I system consists of four core components: Mobile Data Storage (MDS), Read Write Device (SLG), Interface Module (ASM), and Service Test Device (STG).

Mobile Data Storage (MDS)

As a data carrier attached to carriers such as pallets and workpiece carriers, MDS is responsible for carrying and storing production data in the process. The system offers multiple models to meet different needs:

Compact: such as MDS 401 (Φ 30 mm) and MDS 402, using 8KB FRAM, suitable for short distance applications with limited space.

Universal type: such as MDS 403, 404, and 514, providing flexible installation methods and stable read-write performance.

Large capacity model: MDS 506 and 507 are equipped with 32KB memory (FRAM and RAM respectively), among which MDS 507 has a built-in dialogue battery and supports ultra long distance (up to 800mm) read and write with SLG 44.

High temperature resistant type: The MDS 439E adopts a polyphenylene sulfide (PPS) shell and 8KB EEPROM, designed specifically for high-temperature environments such as painting workshops and drying ovens, and can withstand cyclic high temperatures up to 220 ° C.

Read write device (SLG)

SLG is a fixed device that generates an induction field and exchanges data with MDS. Its models are distinguished based on read/write distance and field size:

Short distance: SLG 40/40-S, suitable for precise alignment of close range assembly lines.

Mid range: SLG 41 series (including SLG 41C/41CC) and SLG 42, providing balanced performance and size.

Long distance: SLG 43 has a large transmission window, suitable for large-sized MDS (such as MDS 506) and dynamic operations.

Ultra long distance: The SLG 44 is designed specifically to complement the MDS 507, achieving a hundred meter operating distance and suitable for high-speed or low precision positioning scenarios.

Interface Module (ASM)

ASM is a bridge that connects upper level control systems (such as PLC) with MOBY field components. Rich series, suitable for various control architectures:

SIMATIC S5 Integration: ASM 400/401 can be directly inserted into PLC racks such as S5-115U/135U/155U, and programmed using FB 250 (address access) or FB 230 (file processor) respectively.

Compact PLC: ASM 410 is suitable for small PLCs such as S5-90U/95U/100U and ET 100U, and can be directly controlled through process imaging.

PROFIBUS connection: ASM 450/452/454 supports the PROFIBUS DP/DPV1 protocol for easy distributed installation and integration. ASM 452 and 454 support non periodic communication with high data throughput.

SIMATIC S7 Integration: ASM 470/475 is designed specifically for S7-300/400 and ET 200M. ASM 470 uses FC 47, while ASM 475 serves as a parameterizable module that supports direct address access through FC 45 or file processor functionality through FC 56.

Serial interface: ASM 424 provides RS-232/422 interface and follows the 3964R protocol, making it easy to connect to PCs or third-party controllers.

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor

- SHINKAWA