MOOG DM2020 Multi axis Servo Drive

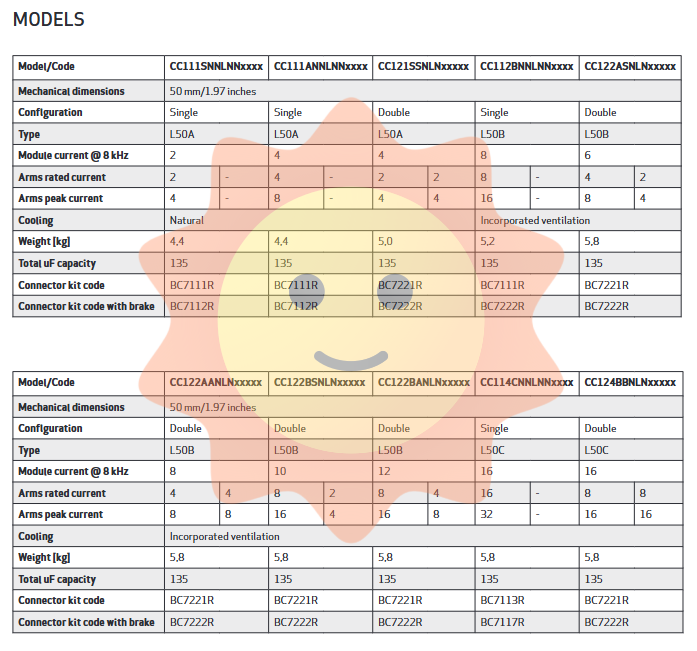

The shaft module is divided into multiple series according to current output, and some typical models are as follows:

Model Series Width Configuration Rated Current (Arms) Peak Current (Arms) Applicable Scenarios

CC126 series 75mm single/double axis 16-32 32-64 small and medium power multi axis

CC128 series 100mm single/double axis 24-64 48-128 medium high power synchronous

CC140 series 200mm single/double axis 48-128 96-256 high-power high dynamic

The power module offers two specifications:

CC201 (50mm): rated at 54A, peak at 130A, suitable for small systems

CC202 (150mm): rated 128A, peak 256A, supports multi module parallel connection

Users can flexibly select based on motor power, number of shafts, dynamic requirements, and cabinet space. Moog also provides application engineering support to assist in system design and component matching.

Application scenarios and industry adaptation

DM2020 is suitable for various industrial scenarios with high requirements for dynamic performance, synchronization accuracy, and energy efficiency:

Industrial robots: multi joint collaboration, high-speed picking and placing, precision assembly

Machine tools and machining centers: multi axis interpolation, spindle positioning, tool replacement

Electronic semiconductor equipment: wafer transfer, surface mount machine, wire bonding

Packaging and material handling: high-speed filling, packing machine, gantry truss

Medical equipment: imaging positioning, surgical robots, rehabilitation devices

Energy conversion system: electric/hybrid power test bench, generator control

In addition, the DM2020 drive is clearly not classified as a "dual-use" product under EC 428/2009, with no export control restrictions, making it easy for global procurement and integration.

Software and User Experience

The accompanying graphical user interface (GUI) provides intuitive parameter settings, real-time monitoring, and diagnostic functions. The system is equipped with high-frequency data recording, automatic identification, and auxiliary calibration tools, which can quickly complete debugging even for complex multi axis systems. Optional memory card (MMC) or USB-C interface for data export and program backup, convenient for on-site maintenance and remote support.

Safety certification and environmental adaptability

The entire DM2020 series complies with CE certification requirements, covering the Low Voltage Directive (2014/35/CE), EMC Directive (2014/30/CE), and Machinery Directive (2006/42/CE). Built in Safety Torque Off (STO) function, supporting SIL CL3 and PL e safety levels, meeting modern mechanical safety standards.

The product environment data is as follows:

Working temperature: 0-40 ° C (maximum 55 ° C derating)

Storage temperature: -25-70 ° C

Humidity range: 15-85% (no condensation)

Installation altitude: ≤ 2000 meters (derating required if exceeding)

Vibration and Shock: Compliant with EN 60721-3-3 Industrial Environmental Classification

Moog full product line collaboration

In addition to the DM2020 multi axis drive, Moog also offers a complete servo motor and drive solution, forming a closed-loop ecosystem:

CD series compact servo motor: torque 0.15-77Nm, high power density

HD series high dynamic servo motor: torque 2-909Nm, extremely high acceleration capability

ExD explosion-proof servo motor: suitable for flammable and explosive environments

CP series compact power motor: short body, high torque design

Distributed drive solutions: such as DR2020 machine mounted and DI2020 motor integrated drives, supporting out of cabinet installation and distributed architecture

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor

- SHINKAWA

- Other Brands