MOOG T161 Series Rack Mount Digital Brushless Motor Controller

All configuration parameters are stored in non-volatile E ² PROM to ensure that settings are not lost after power failure. In addition, optional expansion function cards provide more advanced features, such as programmable encoder simulators (for testing upper control systems) and programmable analog test points (for connecting oscilloscopes to observe internal key signals), greatly enhancing the system's development, testing, and diagnostic capabilities.

Comprehensive protection mechanism: building a strong and reliable defense line

For industrial equipment, reliability is often more important than peak performance. The T161 series is equipped with a rich and responsive protection circuit, forming a comprehensive reliability defense line:

Power and logic monitoring: including power fault monitoring and logic voltage monitoring, to ensure that the control circuit operates at a stable voltage.

Power level protection: Equipped with overcurrent and short circuit protection, it can quickly turn off power devices to prevent hardware damage caused by motor stalling, phase to phase short circuits, and other faults.

Temperature protection: Simultaneously monitor the motor temperature (through the built-in thermistor of the motor) and controller overheating to achieve bidirectional temperature protection, avoiding performance degradation or device aging caused by heat accumulation.

Signal integrity protection: including feedback loss and commutation signal fault detection. Once abnormal rotary signal or internal commutation logic error is detected, the driver will immediately take safety measures to prevent motor runaway or abnormal vibration.

Watchdog timer: monitors the running status of the internal microprocessor to prevent program runaway and system loss of control, and is the highest level of software reliability guarantee.

These protective functions do not exist in isolation, but work together to intervene in the early stages of faults, maximizing the safety of drives, motors, and controlled mechanical equipment.

Mechanical and Environmental Specifications: Designed for Industrial Environments

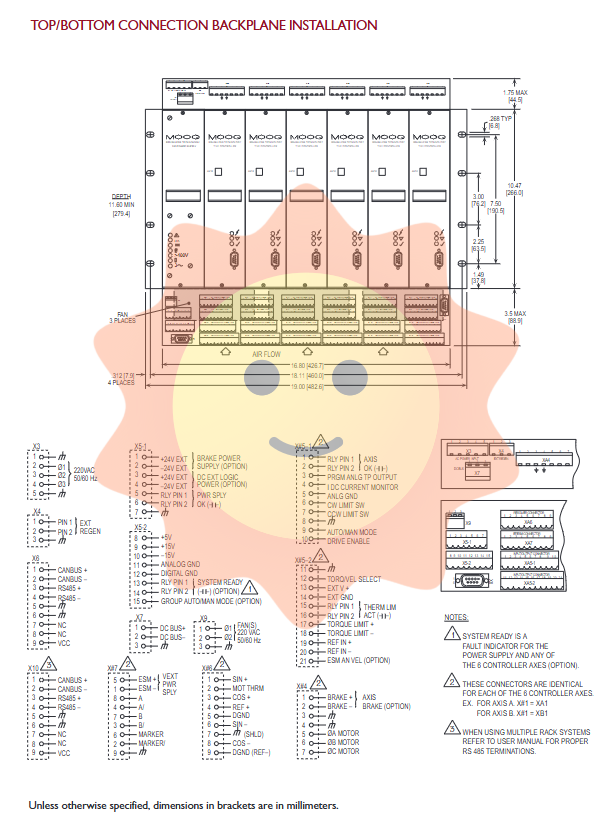

The T161 series adopts a compact package with a built-in heat sink, and its size varies depending on the power model. For example, the width of T161-901/902 is 2.40 inches (61.0 millimeters), while the width of T161-903/904 is 3.60 inches (91.44 millimeters), the depth is uniformly 9.75 inches (247.7 millimeters), and the height is 10.35 inches (262.9 millimeters). This standardized size facilitates planning and installation inside the control cabinet.

To ensure stable operation, the working environment temperature range is from 0 ° C to 55 ° C. The document specifically emphasizes the heat dissipation requirements: when multiple drives are installed in a plug-in box or tray, the total air volume must be no less than 300 CFM (8.49 cubic meters/minute), and the static pressure must be no less than 2.0 inches of water column (approximately 469 pascals). This requires system integrators to fully consider the heat dissipation requirements when designing control cabinet air ducts, in order to avoid derating operation or triggering protection due to overheating.

In terms of electrical input, the T161 series supports direct 220VAC line power supply (single-phase or three-phase), simplifying power supply system design without the need for additional isolation transformers, reducing costs and system complexity.

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor

- SHINKAWA

- Other Brands