MOOG T161 Series Rack Mount Digital Brushless Motor Controller

MOOG T161 Series Rack Mount Digital Brushless Motor Controller

In the fields of high-end industrial automation, precision testing equipment, aerospace simulators, and high dynamic robots, the performance of motion control systems directly determines the accuracy, response speed, and reliability of the equipment. As the core power unit, servo drives play a crucial role in converting control instructions into precise mechanical motion. The T161 series servo drive launched by Moog company, with its innovative modular design, sine wave drive technology, and powerful integrated protection function, has become the preferred solution for dealing with complex and demanding motion control challenges. This article will delve into the technical core, design philosophy, and application value of the T161 series in building high-performance multi axis systems.

Core Architecture: Modular and Scalable Engineering Intelligence

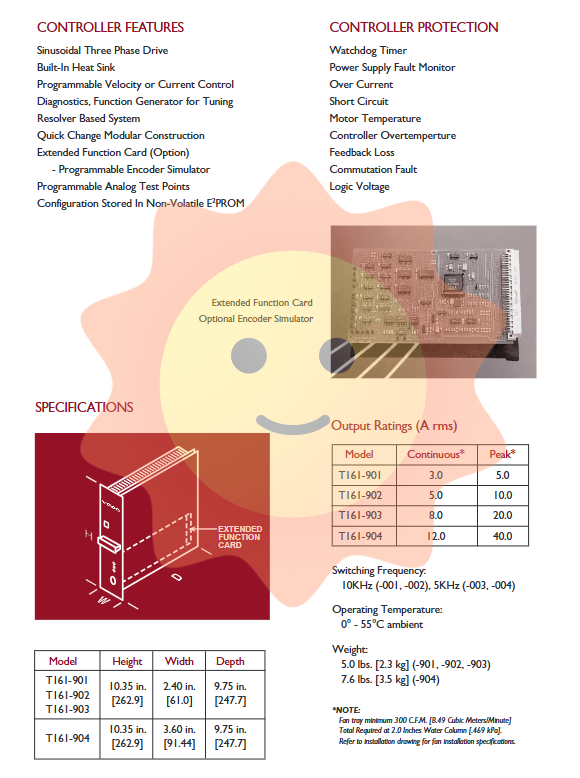

The most striking design feature of the T161 series is its "quick replacement modular construction". This design concept modularizes the main functional units of the driver, making maintenance, upgrades, or module replacement based on power requirements exceptionally easy. This series offers four power models from T161-901 to T161-904, with continuous output currents ranging from 3.0A RMS to 12.0A RMS and peak currents ranging from 5.0A RMS to 40.0A RMS, covering a wide range of needs from small actuators to medium-sized high dynamic loads. All models share the same core architecture and interfaces, ensuring the scalability of system design and the universality of spare parts.

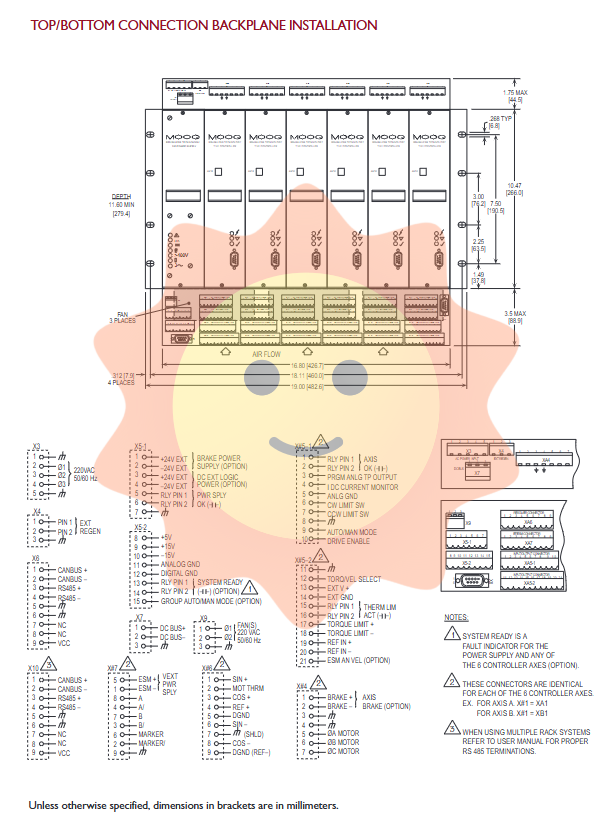

This modular thinking is further reflected in its system integration capability. The T161 series supports 1, 2, 3, 4, or 6-axis PCB backplane integration solutions. By integrating multiple driver modules onto a common backplane, a highly compact and wired multi axis collaborative control system can be constructed. This integration method not only saves valuable space inside the control cabinet and reduces complex external interconnections, but more importantly, it optimizes the delay and synchronization performance of inter axis communication, providing an ideal hardware platform for complex applications that require high-precision interpolation or multi axis synchronization, such as five axis machining and electronic manufacturing equipment.

Drive technology: Performance advantages of sine wave three-phase drive

The T161 series adopts advanced sine wave three-phase drive technology. Compared to traditional square wave or trapezoidal wave drives, sine wave drives control permanent magnet synchronous servo motors by generating smooth and continuously changing current waveforms, which have significant technical advantages:

Lower torque ripple: Sine wave current can generate almost constant electromagnetic torque, greatly reducing the vibration and noise of the motor during low-speed operation, achieving "smooth and silky" ultra-low speed operation, which is crucial for high-precision positioning and scanning applications.

Higher operating efficiency: reduces harmonic losses, resulting in higher overall operating efficiency and less heat generation for the motor and driver.

Wider speed regulation range: While maintaining good control characteristics, it can achieve a wider speed regulation range to meet various working conditions from extremely low speed to high speed.

Combined with a feedback system based on a rotary transformer (Resolver), the T161 series achieves accurate and reliable detection of the position of the motor rotor. As an analog, brushless sensor, the rotary transformer is highly favored in industrial environments that require long-term stable operation due to its excellent anti pollution, anti electromagnetic interference ability, and high reliability. The driver integrates a high-precision RDC (Rotary Digital Converter) circuit internally, which converts the analog signal of the rotary converter into high-resolution digital position and velocity information in real time, forming the cornerstone of closed-loop control.

Control and Configuration: Flexible and Easy to Use User Interface

The T161 series offers two main control modes: programmable speed control and programmable current (torque) control. Users can flexibly choose control modes according to application requirements. For example, in winding systems that require constant tension, torque mode can be used; In conveying systems that require precise speed tracking, speed mode can be used.

The configuration and debugging process fully considers the convenience of the project. Users can operate through two main channels:

Handheld terminal: With a dedicated handheld programmer, technicians can quickly set parameters, perform basic debugging and diagnosis on the device site without connecting to the upper computer, making it particularly suitable for installation and maintenance stages.

PC software "WinDrive" or "MOOGTERM": Connected to a PC through RS-232 or other communication interfaces, using graphical user interface software, it can perform more comprehensive and in-depth parameter configuration, dynamic performance debugging, real-time data monitoring, and fault diagnosis. The integrated diagnostic function and function generator in the software provide powerful tools for engineers to optimize servo loop gain and test system frequency response, simplifying complex tuning processes.

All configuration parameters are stored in non-volatile E ² PROM to ensure that settings are not lost after power failure. In addition, optional expansion function cards provide more advanced features, such as programmable encoder simulators (for testing upper control systems) and programmable analog test points (for connecting oscilloscopes to observe internal key signals), greatly enhancing the system's development, testing, and diagnostic capabilities.

Comprehensive protection mechanism: building a strong and reliable defense line

For industrial equipment, reliability is often more important than peak performance. The T161 series is equipped with a rich and responsive protection circuit, forming a comprehensive reliability defense line:

Power and logic monitoring: including power fault monitoring and logic voltage monitoring, to ensure that the control circuit operates at a stable voltage.

Power level protection: Equipped with overcurrent and short circuit protection, it can quickly turn off power devices to prevent hardware damage caused by motor stalling, phase to phase short circuits, and other faults.

Temperature protection: Simultaneously monitor the motor temperature (through the built-in thermistor of the motor) and controller overheating to achieve bidirectional temperature protection, avoiding performance degradation or device aging caused by heat accumulation.

Signal integrity protection: including feedback loss and commutation signal fault detection. Once abnormal rotary signal or internal commutation logic error is detected, the driver will immediately take safety measures to prevent motor runaway or abnormal vibration.

Watchdog timer: monitors the running status of the internal microprocessor to prevent program runaway and system loss of control, and is the highest level of software reliability guarantee.

These protective functions do not exist in isolation, but work together to intervene in the early stages of faults, maximizing the safety of drives, motors, and controlled mechanical equipment.

Mechanical and Environmental Specifications: Designed for Industrial Environments

The T161 series adopts a compact package with a built-in heat sink, and its size varies depending on the power model. For example, the width of T161-901/902 is 2.40 inches (61.0 millimeters), while the width of T161-903/904 is 3.60 inches (91.44 millimeters), the depth is uniformly 9.75 inches (247.7 millimeters), and the height is 10.35 inches (262.9 millimeters). This standardized size facilitates planning and installation inside the control cabinet.

To ensure stable operation, the working environment temperature range is from 0 ° C to 55 ° C. The document specifically emphasizes the heat dissipation requirements: when multiple drives are installed in a plug-in box or tray, the total air volume must be no less than 300 CFM (8.49 cubic meters/minute), and the static pressure must be no less than 2.0 inches of water column (approximately 469 pascals). This requires system integrators to fully consider the heat dissipation requirements when designing control cabinet air ducts, in order to avoid derating operation or triggering protection due to overheating.

In terms of electrical input, the T161 series supports direct 220VAC line power supply (single-phase or three-phase), simplifying power supply system design without the need for additional isolation transformers, reducing costs and system complexity.

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor

- SHINKAWA

- Other Brands