Eaton MTLx544-S Series (MTL4544/S, MTL5544/S) Relay Power Supply

Eaton MTLx544-S Series (MTL4544/S, MTL5544/S) Relay Power Supply

Product core positioning

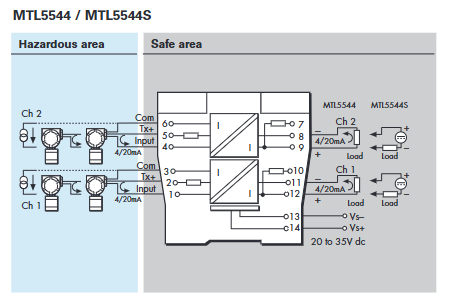

The MTLx544-S series (including MTL4544/S and MTL5544/S) is an industrial grade two channel relay power supply launched by the MTL brand under Eaton. Its core is used for 4/20mA signal transmission and power supply between hazardous and safe areas. It provides full floating DC power supply for 2-wire/3-wire 4/20mA transmitters or HART smart transmitters in hazardous areas (such as Zone 0, Div. 1), while relaying signals to loads in safe areas. It also supports bidirectional transmission of HART digital communication signals on the 4/20mA current loop (only MTLx544, MTLx544S is in current sink mode), suitable for process industry scenarios with explosive environments such as petrochemicals, natural gas, pharmaceuticals, etc.

Key technical specifications

1. Channel and signal characteristics

Number of channels: 2 independent channels, supporting simultaneous power supply and signal relay for 2 transmitters

Signal range - hazardous area input: 0~24mA (including over range)

-Safe zone output (MTLx544): 4~20mA (standard), 0~24mA (full range)

-Safe Area Current Sink (MTLx544S): Supports external current source input, maximum load impedance of 600 Ω

Transmission accuracy - better than 15 μ A at 20 ℃ (low error, ensuring signal fidelity)

-Temperature drift:<0.8 μ A/℃ (high signal stability in a wide temperature environment)

Response time of 10% of the final value within 50 μ s (fast response, suitable for dynamic measurement scenarios)

2. Power supply and load capacity

Dangerous area transmitter power supply - output voltage: 16.5V at 20mA (meets the power supply requirements of most 2-wire transmitters)

-Power characteristics: Fully floating DC power supply, avoiding interference from grounding loops

Safe Area Power Input - Voltage Range: 20~35V DC

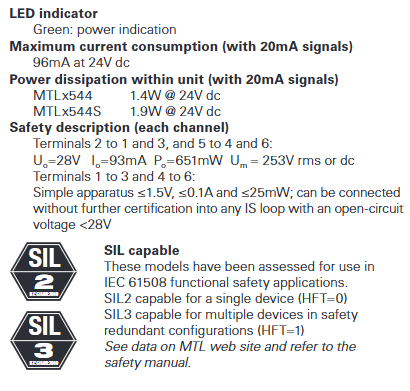

-Maximum current consumption (at 20mA signal): 96mA at 24V DC

-Power dissipation: MTLx544 is 1.4W@24V DC, MTLx544S is 1.9W@24V dc

Safe Area Load Capacity - MTLx544 (Drive Load): Maximum Load Impedance of 360 Ω at 24mA and 450 Ω at 20mA

-MTLx544S (current sink): maximum voltage source 24V dc, output impedance>1M Ω (low leakage, reducing signal interference)

Signal ripple safe area circuit ripple<50 μ V peak to peak value (low noise, ensuring signal purity)

3. Adaptation to hazardous areas and safety compliance

Hazardous Area Certification - Applicable Areas: Zone 0 (IIC, T4~T6), Div. 1 (Group A) (requires corresponding certified transmitters)

-Security parameters (per channel):

-Terminal 2-1/3, 5-4/6: U=28V, I ₀=93mA, P ₀=651mW, U ₘ=253V rms (AC/DC)

-Terminals 1-3, 4-6: Simple devices (≤ 1.5V, ≤ 0.1A, ≤ 25mW) that can be connected to intrinsically safe (IS) circuits with open circuit voltage<28V

Functional Safety (SIL) - Single Device: SIL 2 Capability (HFT=0, Hardware Fault Tolerance 0)

-Redundant configuration: SIL 3 capability (HFT=1, hardware fault-tolerant 1)

-Standard: Compliant with IEC 61508 functional safety standard, specific application configuration needs to be confirmed with reference to the safety manual

4. Communication and Instruction

Communication Support - MTLx544: Supports HART digital communication (only terminal 1-2, 4-5 channels), enabling bidirectional digital signal transmission on a 4/20mA current loop (compatible with intelligent transmitter debugging and data reading)

-MTLx544S: Does not support HART communication (only current sink function)

LED indicator green LED: power status indicator (lights up when the power is normal for on-site troubleshooting)

Core functions and differences

1. Common functions

Fully floating power supply: provides isolated DC power supply for transmitters in hazardous areas, avoiding signal interference caused by grounding loops and improving measurement accuracy;

Signal relay and protection: safely transmit 4/20mA signals from hazardous areas to safe area loads, while ensuring the intrinsic safety characteristics of hazardous area circuits through safety parameter limitations such as voltage, current, and power;

Wide temperature stability: Low temperature drift (<0.8 μ A/℃), suitable for industrial environments -40 ℃~+70 ℃ typical working temperature (not specified in the document, refer to similar MTL products), ensuring the reliability of the signal under temperature fluctuations.

2. Model difference (MTLx544 vs MTLx544S)

Features MTLx544 (including MTL4544, MTL5544) MTLx544S (including MTL4544S, MTL5544S)

Safe Area Working Mode Current Source Mode: Actively Drive Safe Area Load (Output 4/20mA Signal) Current Sink Mode: Receive External Current Source Signal as Passive Load (such as 4-Wire Transmitter Output)

HART communication support (terminals 1-2, 4-5 channels) not supported

Load impedance limit: 360 Ω at 24mA, 450 Ω at 20mA, maximum 600 Ω

Typical applications include 2-wire/3-wire 4/20mA/HART transmitters (requiring power supply and signal transmission), 4-wire transmitters (with built-in power supply, only requiring signal reception), or external current source signal acquisition

Typical application scenarios

Petrochemical site: Supply power to pressure and temperature transmitters in Zone 0, relay signals to DCS/PLC systems in safe areas, and read transmitter diagnostic data through HART;

Natural gas processing plant: Flow transmitter signal transmission in Div. 1 area, utilizing SIL redundant configuration (multiple devices in parallel) to meet SIL 3 safety loop requirements;

Pharmaceutical industry: Power supply and signal isolation of liquid level transmitters in explosion-proof workshops to avoid power interference affecting the control accuracy of drug production processes.

Installation and Precautions

Wiring specifications: Wiring in hazardous areas must comply with the requirements of intrinsic safety circuits (such as using shielded twisted pair cables and single ended grounding of the shielding layer), and the corresponding terminals must strictly follow the manual (such as MTL4544 terminals 1-3 for channel 1 hazardous areas and 7-10 for safe area loads);

Power adaptation: The input power supply in the safe area should be stable at 20-35V DC to avoid voltage fluctuations that may cause device restarts or signal abnormalities;

HART communication: Only MTLx544 supports HART. It is necessary to ensure that the communication cable impedance matches (MTL recommended cable is recommended) to avoid digital signal attenuation;

Redundant configuration: If SIL 3 capability is required, multiple devices should be redundantly connected (HFT=1) and a functional safety assessment should be completed by referring to the MTL safety manual.

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor

- SHINKAWA

- Other Brands