Woodward MicroNet ™ Simplex Digital Control MicroNet ™ Plus Digital Control

Woodward MicroNet ™ Simplex Digital Control MicroNet ™ Plus Digital Control

Introduction to Core Modules

Actuator module

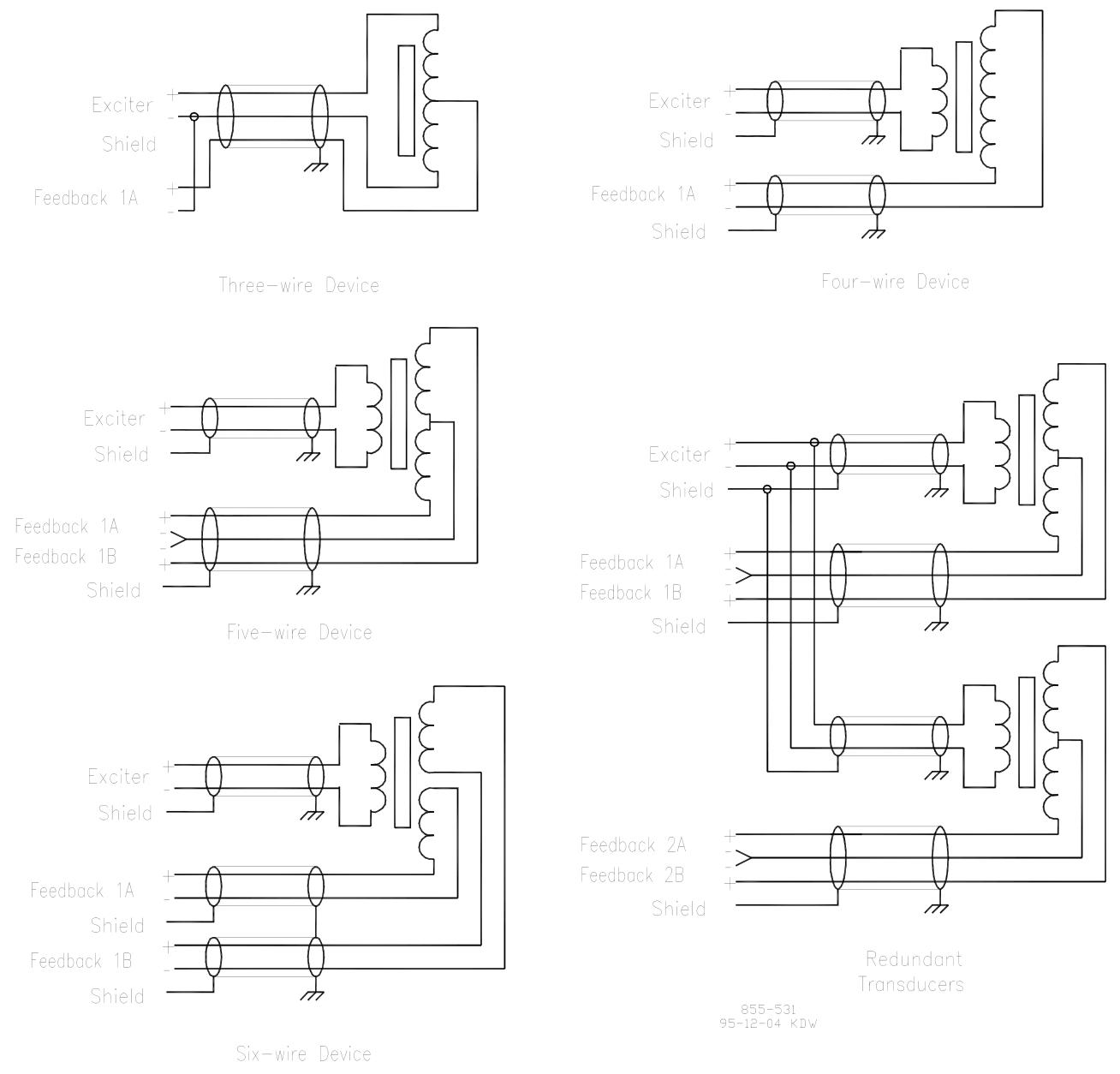

Dual channel actuator controller: supports proportional or integral hydraulic/pneumatic actuators, with up to two position feedback devices per channel and multiple current range versions for precise position control. It has complete fault detection functions, such as driver current error, open circuit, short circuit and other fault alarms.

Four channel actuator module: receives digital information from the CPU, generates four proportional actuator drive signals, outputs current range of 0-25mA or 0-200mA, has high accuracy and stability, and can monitor actuator impedance and other faults.

Simplex real-time SIO module: includes three RS-485 ports for communication with EM or GS/LQ digital actuator drivers, with fast update rates, supports remote monitoring and configuration of driver parameters, and has communication fault detection capabilities.

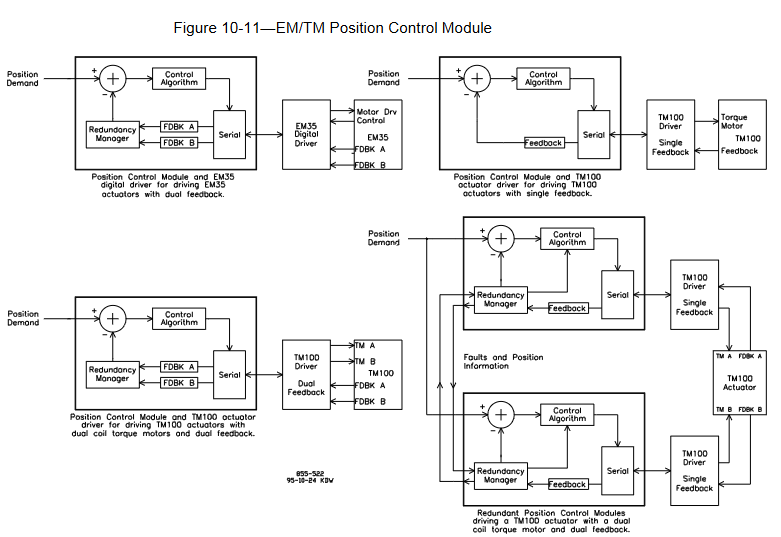

EM/TM position controller: receives reference input from the CPU and feedback input from the remote drive, controls the remote drive through a serial link, and is mainly used in systems with high precision requirements, such as dry low emission (DLE) systems.

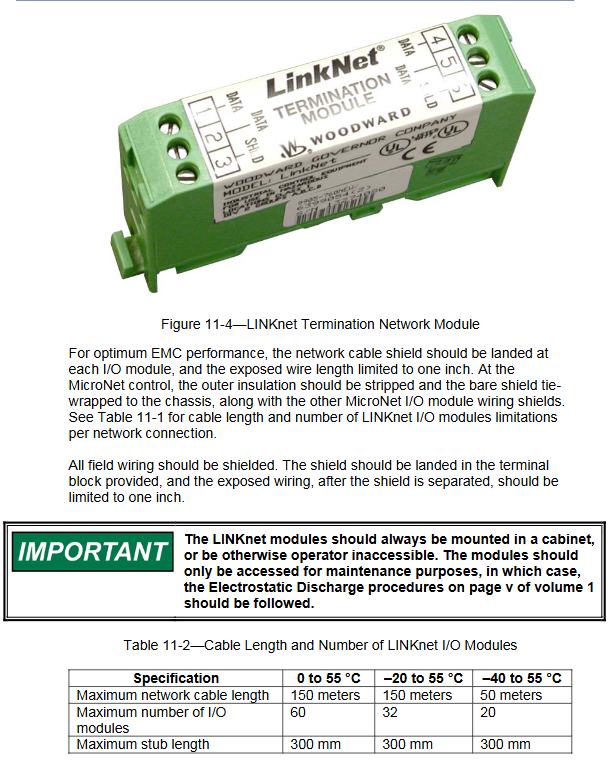

LINKnet I/O Network

Four channel LINKnet controller module: As the network master station, it provides four independent network trunks, each trunk can connect up to 60 I/O modules, responsible for controlling data flow between CPU modules and I/O nodes, and monitoring node health status.

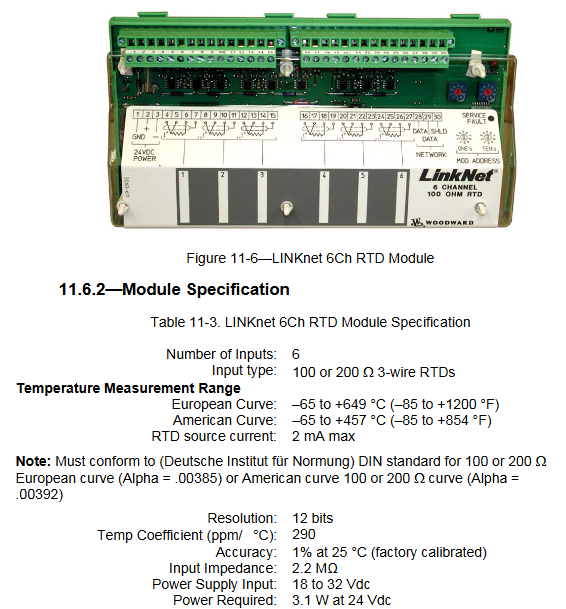

Various types of LINKnet I/O modules, including 6-channel RTD modules, 6-channel thermocouple (T/C) modules, 6-channel current input modules, 16 channel discrete input modules, 6-channel analog output modules, 8-channel discrete output modules, etc., are used for the acquisition and output of different types of signals, and all have corresponding fault detection and isolation functions.

Specialized functional module

Pressure sensor interface module: communicates with external pressure sensors, has two isolated RS-422 communication ports, can connect up to eight pressure sensors, and shares pressure data with the main CPU module through dual port RAM on the VME bus.

Dual overspeed module: monitors two independent frequency (shaft speed) inputs, detects overspeed and input faults, mainly used for General Electric LM (land and marine) gas turbines, usually used in conjunction with dual soleoid monitoring modules.

Dual soleoid monitoring module: monitors and controls two independent soleoid current inputs, detects low or high current faults, directly interfaces with the gas turbine fuel cut-off valve soleoid, and requires an external soleoid driver component.

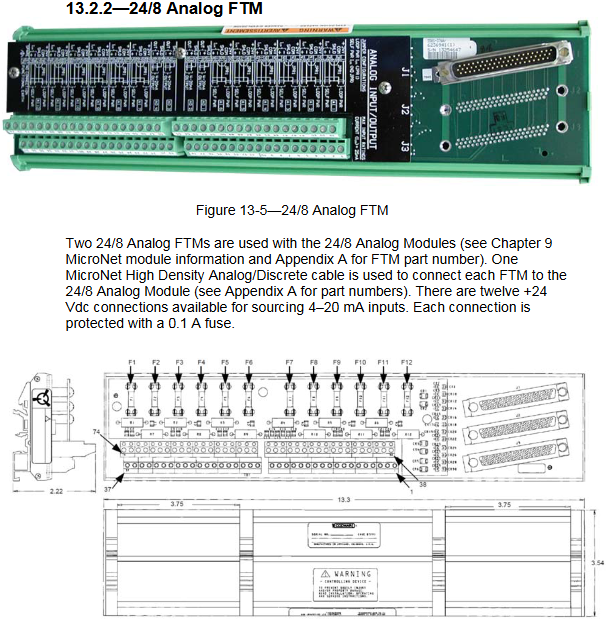

Field Terminal Modules (FTMs): Used to connect field wiring to the front-end of MicroNet controlled I/O modules, providing cage clamp terminal connection points to achieve shielded termination and EMI protection. There are multiple types, such as analog I/O FTMs, discrete I/O FTMs, etc., suitable for different I/O modules and signal types.

Installation and replacement process

Pre installation information: including storage conditions (temperature -20 to+70 ° C, maximum relative humidity of 90% non condensing), unpacking inspection (for damage), equipment location selection (dry, temperature 0-55 ° C, humidity not exceeding 90% non condensing, good ventilation, etc.).

Installation steps: including VME I/O module installation, MicroNet Simplex power module installation, 16/32 channel relay box installation, FTMs installation, etc. Detailed installation methods and precautions for each component are explained, such as avoiding forced installation and correctly connecting cables.

Replacement steps: involving the replacement of VME I/O modules, on-site terminal modules (FTM), relay boxes, socket installed relays, I/O cables, chassis fans, etc., emphasizing safety precautions such as power-off operation in explosive environments and preventing electrostatic discharge.

Service Options

Product service options: including troubleshooting guides in the manual, contacting system manufacturers or packagers, contacting Woodward full-service distributors, contacting Woodward technical support, etc.

Woodward factory service options: including replacement/exchange (24-hour service), uniform rate repair, uniform rate remanufacturing, etc., can be selected according to needs.

Equipment return for repair: It is necessary to contact the full-service distributor in advance to obtain return authorization and transportation instructions. Appropriate materials should be used for packaging, and relevant regulations such as anti-static should be followed.

Replacement parts: When ordering, please provide the part number and unit serial number on the shell nameplate.

Engineering services: including technical support, product training, on-site services, etc., which can be obtained through phone, email, or website contact.

Appendix Information

Module Compliance Information Matrix: lists the model, status, description, extended description, and various certification standards that each module complies with, such as CSA, UL, ATEX, CE (LVD), CE (EMC), ABS, DNV, LRS, etc.

Environmental specifications: including operating temperature, storage temperature, humidity, vibration, impact, altitude, air quality, installation overvoltage level, protection level, sound level, weight, dielectric strength, etc.

MicroNet hardware and software compatibility: describes the compatibility of different encoders (Coders) and CPU modules on different control platforms, as well as the compatibility of various modules.

Declaration of conformity: Declare that the product complies with relevant directives and standards, such as the Electromagnetic Compatibility (EMC) directive, the Directive on Potential Explosive Environments, etc.

Abbreviations: Explained the meanings of various abbreviations used in the manual to facilitate understanding of the content.

Important Warning and Precautions

The importance of electrostatic discharge protection was emphasized, and corresponding preventive measures should be taken when operating electronic control equipment.

Identify countermeasures for dangerous situations such as overspeed, overtemperature, and overpressure, such as equipping independent shutdown devices.

Remind to pay attention to safety when installing and replacing modules, and avoid operating under live conditions, especially in hazardous locations.

Emphasis was placed on the importance of proper grounding, shielding termination, cable routing, etc. for system performance and safety.

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor

- SHINKAWA

- Other Brands