ABB NE802; NE802 Network switch 3BSE080237R1

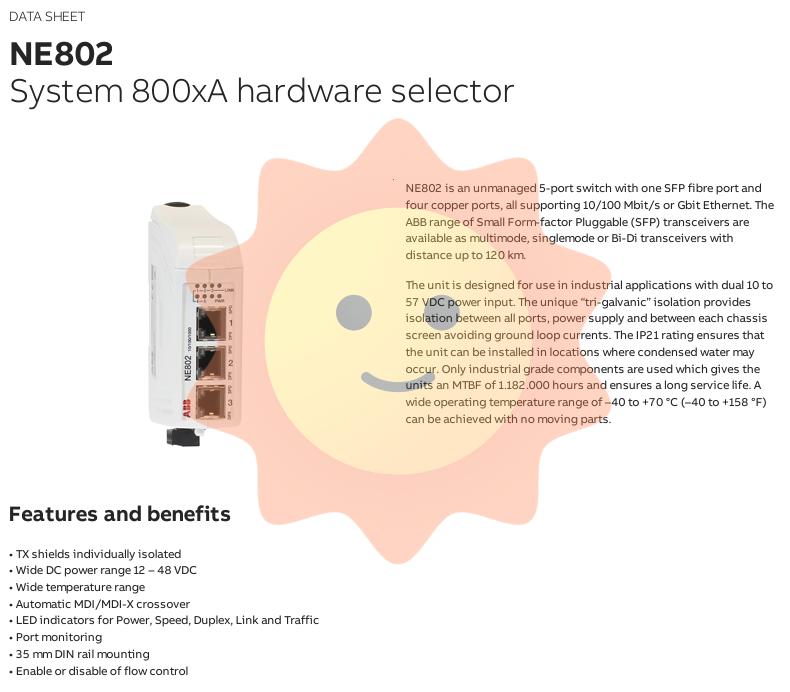

The unit is designed for use in industrial applications with dual 10 to 57 VDC power input. The unique “tri-galvanic” isolation provides isolation between al ports, power supply and between each chassis screen avoiding ground loop currents. The IP21 rating ensures that the unit can be instaled in locations where condensed water may occur. Only industrial grade components are used which gives the units an MTBF of 1.182.000 hours and ensures a long service life. wide operating temperature range of –40 to +70 °C (–40 to +158 °F) can be achieved with no moving parts.

ABB NE802; NE802 Network switch 3BSE080237R1

The unit is designed for use in industrial applications with dual 10 to 57 VDC power input. The unique “tri-galvanic” isolation provides isolation between al ports, power supply and between each chassis screen avoiding ground loop currents. The IP21 rating ensures that the unit can be instaled in locations where condensed water may occur. Only industrial grade components are used which gives the units an MTBF of 1.182.000 hours and ensures a long service life. wide operating temperature range of –40 to +70 °C (–40 to +158 °F) can be achieved with no moving parts.

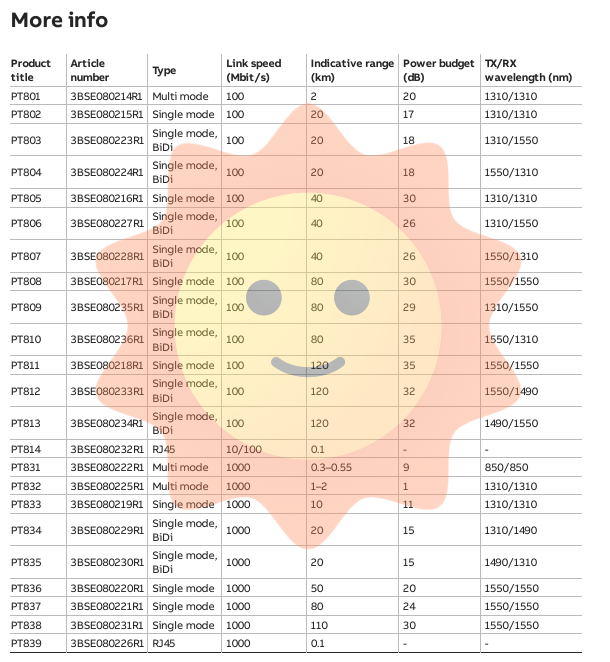

More info

Product、title、Article、number Type Link speed(Mbit/s)、Indicative range(km)、Power budget(dB)、TX/RX、wavelength (nm)

PT801 3BSE080214R1 Multi mode 100 2 20 1310/1310

PT802 3BSE080215R1 Single mode 100 20 17 1310/1310

PT803 3BSE080223R1 Single mode,

BiDi 100 20 18 1310/1550

PT804 3BSE080224R1 Single mode,

BiDi 100 20 18 1550/1310

PT805 3BSE080216R1 Single mode 100 40 30 1310/1310

PT806 3BSE080227R1 Single mode,

BiDi 100 40 26 1310/1550

PT807 3BSE080228R1 Single mode,

BiDi 100 40 26 1550/1310

PT808 3BSE080217R1 Single mode 100 80 30 1550/1550

PT809 3BSE080235R1 Single mode,

BiDi 100 80 29 1310/1550

PT810 3BSE080236R1 Single mode,

BiDi 100 80 35 1550/1310

PT811 3BSE080218R1 Single mode 100 120 35 1550/1550

PT812 3BSE080233R1 Single mode,

BiDi 100 120 32 1550/1490

PT813 3BSE080234R1 Single mode,

BiDi 100 120 32 1490/1550

PT814 3BSE080232R1 RJ45 10/100 0.1--

PT831 3BSE080222R1 Multi mode 1000 0.3–0.55 9 850/850

PT832 3BSE080225R1 Multi mode 1000 1–2 1 1310/1310

PT833 3BSE080219R1 Single mode 1000 10 11 1310/1310

PT834 3BSE080229R1 Single mode,

BiDi 1000 20 15 1310/1490

PT835 3BSE080230R1 Single mode,

BiDi 1000 20 15 1490/1310

PT836 3BSE080220R1 Single mode 1000 50 20 1550/1550

PT837 3BSE080221R1 Single mode 1000 80 24 1550/1550

PT838 3BSE080231R1 Single mode 1000 110 30 1550/1550

PT839 3BSE080226R1 RJ45 1000 0.1--

Rated Current:100 mA @ 12 VDC

Environmental and certification

Precautions

Safety specifications are generally applicable to control system handling. Instructions and warnings related to a specific subject or operation of the product.

The following norms must be strictly observed:

must strictly comply with the technical specifications and typical applications of the product system

Personnel training: Only trained personnel shall install, operate, maintain or repair the product system. must

Provide guidance and explanation of the situation in danger areas to these personnel.

Unauthorized changes: Changes or structural changes to the product system may not be made.

Maintenance responsibility: Must ensure that the product system is used only under appropriate conditions and in full fitness for use.

Working environment: The user must meet the specified environmental conditions:

Safety regulation

The following safety provisions of EN 50110-1 shall be fully complied with when handling product systems (maintenance) :

1 Disconnect completely.

2 Secure to prevent reconnection.

3 Verify that the installation is complete.

4 Ground and short-circuit the device.

Warning: Only qualified maintenance personnel can remove and insert the module. In order to ensure the personal safety of the operator, before each pulling out or inserting, you must

Disconnect the power supply and ensure that there is no voltage on all terminals at the back, and the product is effectively grounded with the ground screw at the back.

Installation precautions

First, the importance of industrial equipment installation

In modern industrial production, various equipment and machines are widely used in various fields, such as manufacturing, energy industry, chemical industry and so on. The installation of industrial equipment is directly related to production efficiency and product quality. Proper installation and commissioning of good equipment can ensure the stable operation of the production line, improve production efficiency and product quality, reduce maintenance costs, and ensure the safety of employees.

Second, the steps of industrial equipment installation

1. Preparation: Before the installation of industrial equipment, it is necessary to carry out adequate preparation work. This includes the tools and equipment required for installation, cleaning and preparation of the installation site, and making installation plans and schedules.

2. Determine the installation position: Determine the installation position of the equipment according to the requirements of the equipment and the layout of the production line. When determining the location, the weight and size of the equipment need to be considered, as well as the coordination of the equipment with the surrounding environment.

3. Install the device: Assemble and install the device according to the installation instructions. Ensure that the device is securely and accurately connected, while protecting the appearance and internal components of the device.

4. Connect power supplies and pipelines: For devices that require power supplies and power supplies, properly connect power supplies and pipelines. The connection of power supply and pipeline should comply with safety standards to avoid hazards such as electric shock and leakage.

5. Commissioning the device: After the installation is complete, you need to commission the device to ensure that the device can run properly. It includes checking the functions and performance of the equipment, adjusting the parameters and Settings of the equipment, and carrying out the necessary tests and inspections.

6. Training operators: After the installation of the equipment, it is necessary to train the operators to understand the operation methods and precautions of the equipment, and improve the operation skills and safety awareness of the employees.

Third, industrial equipment installation precautions

1. Safety first: When installing industrial equipment, safety is the most important consideration. You must operate in strict accordance with safety regulations and wear necessary protective equipment to ensure the safety of the workplace.

2. Strictly follow the equipment instructions: Industrial equipment usually comes with detailed installation instructions, you must carefully read and understand the contents of the instructions, and install the operation in accordance with the requirements of the instructions.

3. Pay attention to the assembly sequence: When installing the device, follow the correct assembly sequence to ensure that all components of the device are assembled correctly to avoid equipment failures or safety accidents caused by incorrect assembly sequence.

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor

- SHINKAWA

- Other Brands