Woodward ProTech GII overspeed protection device (triple module redundancy)

According to the system design, ProTech GII has two output types: two dual redundant trip relay outputs using a 2-out-of-3 voting architecture, or three independent non voting trip relay outputs. Its independent alarm relay, 4-20 mA speed reading, and Modbus ® Communication function makes it easy to integrate into any turbine safety system.

Woodward ProTech GII overspeed protection device (triple module redundancy)

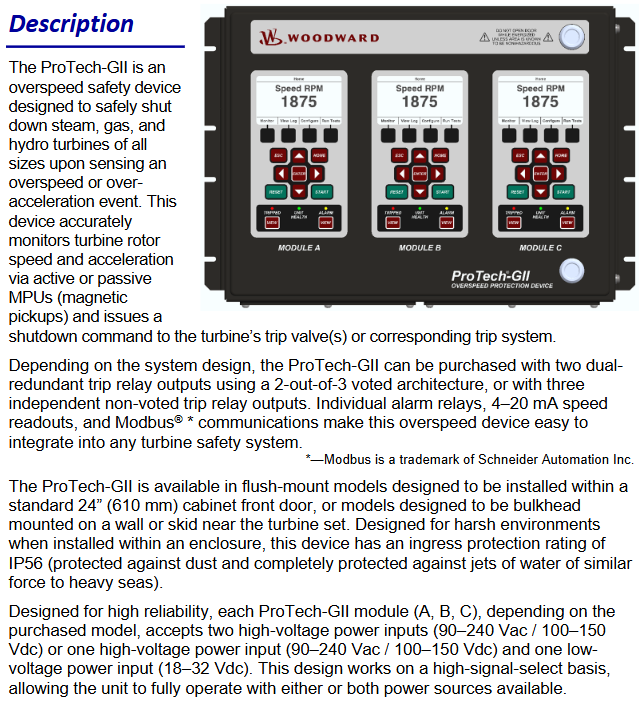

Product description

ProTech GII is an overspeed safety device designed to safely shut down steam, gas, and water turbines of all sizes when overspeed or over acceleration events are detected. It accurately monitors the turbine rotor speed and acceleration through active or passive magneto electric sensors (MPUs), and sends shutdown commands to the turbine's trip valve or corresponding trip system.

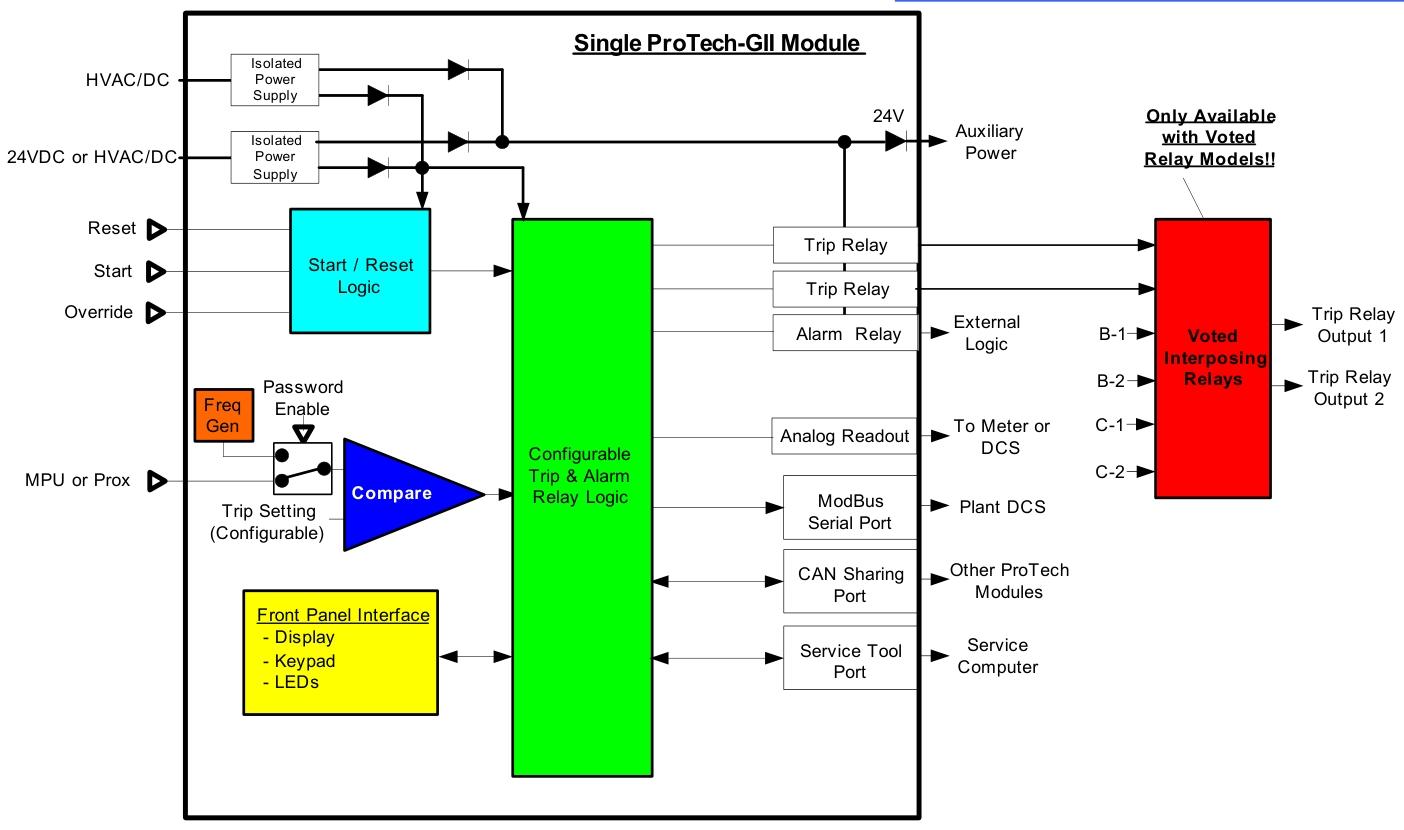

According to the system design, ProTech GII has two output types: two dual redundant trip relay outputs using a 2-out-of-3 voting architecture, or three independent non voting trip relay outputs. Its independent alarm relay, 4-20 mA speed reading, and Modbus ® Communication function makes it easy to integrate into any turbine safety system.

The device comes in embedded models (designed for installation inside a standard 24 inch (610 mm) cabinet front door) and wall mounted models (designed for installation on walls or bases near turbines). When installed inside the casing, it is suitable for harsh environments and has a protection level of IP56 (dustproof, completely preventing water jets similar to giant waves).

To improve reliability, each ProTech GII module (A, B, C) can accept two high voltage power inputs (90-240 Vac/100-150 Vdc) or one high voltage power input (90-240 Vac/100-150 Vdc) and one low voltage power input (18-32 Vdc) depending on the purchased model. This design is based on the principle of high signal selection, allowing the device to operate normally when either or both power sources are available.

Application scenarios

ProTech GII is used to safely shut down steam, gas, and water turbines when turbine overspeed or over acceleration events are detected. Its 12 millisecond response time and speed range of 0.5 to 80000 rpm make it suitable for various types and sizes of turbines.

It can be used in conjunction with turbine control or trip systems, and interfaces with related control systems or factory DCS (distributed control system) through redundant hard wired input and output signals or triple redundant serial Modbus communication ports. An Ethernet gateway can also be selected to easily access the factory Ethernet network.

As a safety device certified by IEC61508 SIL-3 (Safety Integrity Level 3), it can be easily applied to safety systems based on IEC61508 or IEC61511.

Main functions and features

Online testing: Each ProTech GII module can be manually tested through the module front panel, Modbus communication port, or automatically tested through its automatic testing program functionality. Allow users to configure overspeed testing, which is automatically executed on a regular basis, testing each module (A, B, C) one by one, recording each test result, or stopping testing when an error is detected.

Online maintenance: The triple module design allows users to easily replace one of the modules (A, B, C) while the turbine is running normally online. The plug and play structure of the device's backplane and its module to module learning function improve the convenience of replacement.

Trip, alarm, and overspeed logs: The log function records all trip, alarm, trip valve response times, and overspeed events. The trip log function uses a rolling buffer to record the last 50 detected trip or alarm events and the last 20 overspeed events along with their respective times in memory. Each log file can be viewed from the front panel of the device or downloaded to the computer through the ProTech GII service tool program. Each module uses non-volatile memory to ensure that all recorded events can be saved even in the event of a power outage.

Real time clock: Each ProTech GII module uses a real-time clock to ensure accurate time recording. Special time averaging function is used between modules to ensure clock synchronization.

Acceleration detection: configurable to protect the turbine from high acceleration events. Use the derivative of the velocity signal to detect turbine acceleration and issue relevant trip commands.

MPU detection: The speed sensor input of each module uses a special MPU disconnection detection circuit to verify whether the MPU is correctly connected before the turbine runs, and uses special speed loss detection logic to verify the MPU function during the turbine runs.

Automatic overspeed testing program: It can be configured to periodically perform overspeed testing on each module, and then record and report the test results. Simulate overspeed conditions through an internal frequency generator to complete the test sequence for each module.

Anti sulfur pollution: Using special conformal coating materials, it has excellent long-term protection against H2S and SO2 gases in the 3C2 environment specified in the international standard IEC 721-3-3 1994.

Configuration information

Collocation method

ProTech GII can be configured (programmed) through its front panel keyboard or software service tools running on on-site computers or laptops. For ease of use, all configuration settings, alarm/trip, and overspeed logs can be viewed through the high-resolution 4.2-inch (107 mm) color display screen of each module.

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor

- SHINKAWA

- Other Brands