How to install ABB S500 series heavy-duty circuit breaker?

How to install ABB S500 series heavy-duty circuit breaker?

Product Overview

The S500 series heavy-duty circuit breaker is a low-voltage electrical protection equipment launched by ABB, designed to cope with the increasing short-circuit current in low-voltage power grids, with high safety, reliability, and breaking capacity. Its core function is to protect circuits, motors, equipment, and systems from the effects of overload and short-circuit currents through thermal and/or electromagnetic trip functions.

The main features of this series of products include:

High rated breaking capacity, up to 30/50 kA

High rated operating voltage (400/690 VAC, 750 VDC)

Capable of energy and current limiting breaking, with extremely short breaking time

Optimized selectivity ensures that only the faulty part is disconnected in the event of a malfunction

Reliable switch and contact position indication

Compact size (compliant with DIN standards)

Rich accessories (such as undervoltage release, shunt release, auxiliary contacts, and signal contacts, etc.)

Widely applicable in various fields, including railways, commercial buildings, offshore platforms, ships, processing industries, and rail trams.

Main product types and applications

1. Circuit protection category

S500-B: Suitable for circuits that generate minimal or no surge current in power supply equipment (such as boilers, electric heaters, stoves).

S500-C: "Standard" miniature circuit breaker, suitable for powering electrical equipment (such as inductive devices, televisions, fluorescent lamps, gas discharge lamps) and sockets that generate surge currents.

S500-D: Suitable for circuits that supply power to electrical equipment that generates extremely high surge currents, such as transformers and capacitor banks, and can also serve as a protective device for upstream circuit breakers.

2. Motor protection category

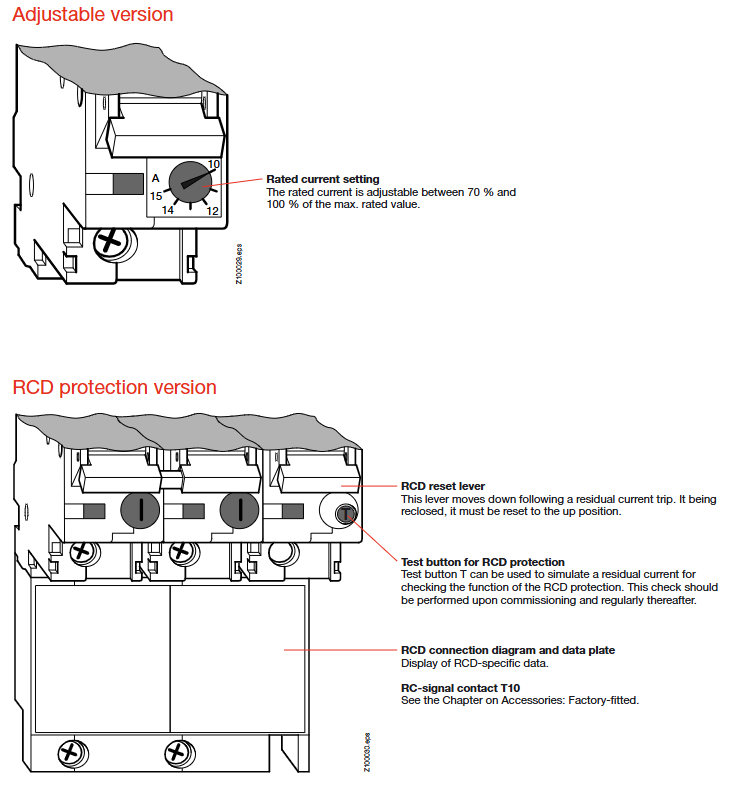

S500-K: Used to protect single-phase and three-phase motors, can be installed in a fuse free motor control center (MCC), and the rated current can be adjusted.

S500-KM: Provides short-circuit protection for motors, combining the functions of contactors and thermal overload relays, with only electromagnetic trip function.

S500X-AG0084: As an alternative product to S500-KM, it is suitable for installation in high short-circuit current scenarios and needs to be used in conjunction with additional overload protection devices.

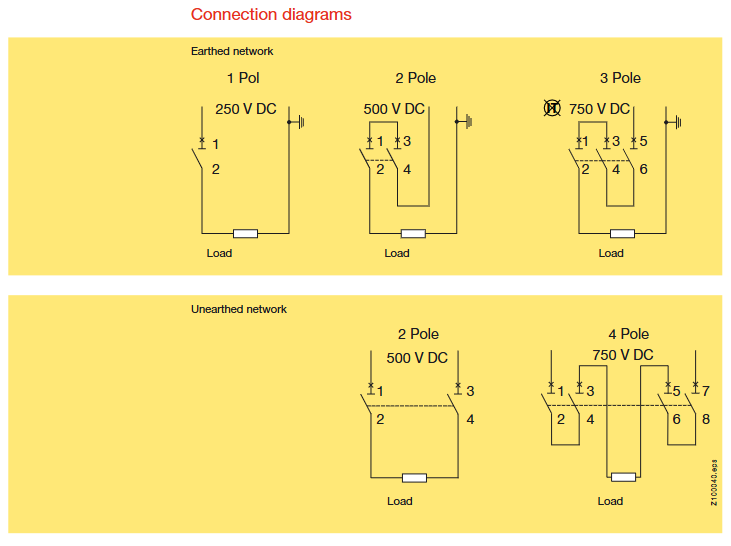

3. DC circuit protection category

S500UC-B: Used for circuits and electrical equipment in DC networks and DC powered vehicles, with a fixed rated current.

S500UC-K: Used for circuits and electrical equipment in DC networks and DC powered vehicles, with adjustable rated current.

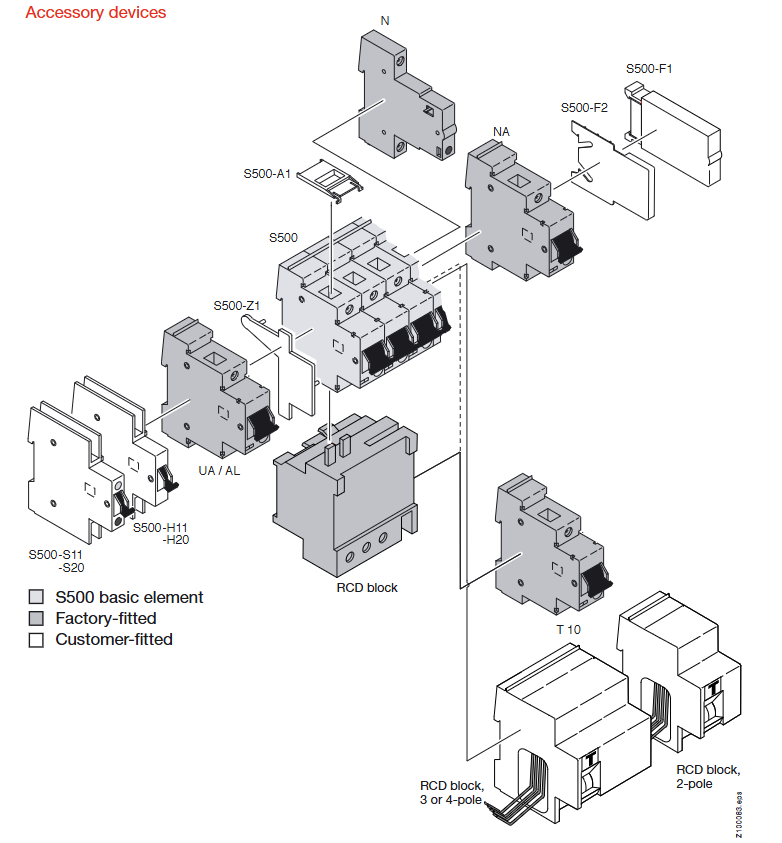

4. Equipped with residual current protection

F500-C, F500-D: Combination circuit breakers with circuit protection characteristics and built-in residual current protection.

F500-K: A combination circuit breaker with motor protection features and built-in residual current protection.

DDA series: residual current protection device that can be installed by customers on S500 heavy-duty circuit breakers, suitable for sinusoidal AC residual current and pulse residual current in DC circuits.

Technical parameters

1. General parameters

Rated voltage: 400/690 VAC, 750 VDC

Rated insulation voltage: 690 VAC, 750 VDC

Rated breaking capacity (according to IEC 60947-2): 50 kA

Frequency: 50/60 Hz, can provide 16 2/3 Hz, 60-400 Hz according to requirements

Environmental temperature: -25 ° C...+55 ° C

Mechanical lifespan:>20000 switch cycles

Protection level: IP20

2. Special parameters for different types of products

Product Type Rated Current Range Tripping Characteristics

S500-B, S500-C, S500-D 6... 63A thermal release: 1.13... 1.45 xIn; Electromagnetic release: 3... 5 xIn (Type B), 5... 10 xIn (Type C), 10... 20 xIn (Type D)

S500-K 0.1... 45A thermal release: 1.05... 1.2 xIn; Electromagnetic release: 8... 14 xIn depending on the current

S500UC-B 6... 63A thermal release: 1.13... 1.45 xIn; Electromagnetic release: 5... 7 xIn (DC)

S500UC-K 0.1... 45A thermal release: 1.05... 1.2 xIn; Electromagnetic trip: 8... 14 xIn (DC) depending on the current

Selective and backup protection

Selectivity: In low-voltage distribution systems, when a short circuit occurs, two or more overcurrent devices connected in series should be selectively disconnected to ensure the continuity of power supply. The S500 heavy-duty circuit breaker has good selectivity compared to upstream circuit breakers due to its low passing energy and fast breaking ability.

Backup protection: If the short-circuit current at the installation point does not exceed 50/30 kA, the S500 heavy-duty circuit breaker can be installed with or without any size of upstream circuit breaker or backup fuse. If the short-circuit current exceeds its breaking capacity, the rated current of the upstream S500 circuit breaker shall not exceed the specified value.

Attachment

1. Factory installation accessories

Including switch neutral wire NA, separation neutral wire N, undervoltage release UA, shunt release AL, residual current release signal contact T10, etc.

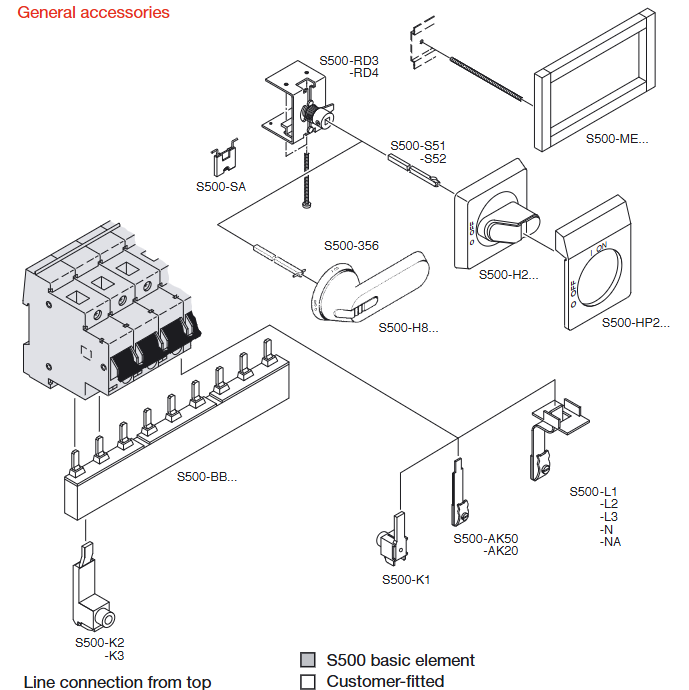

2. Customers install accessories

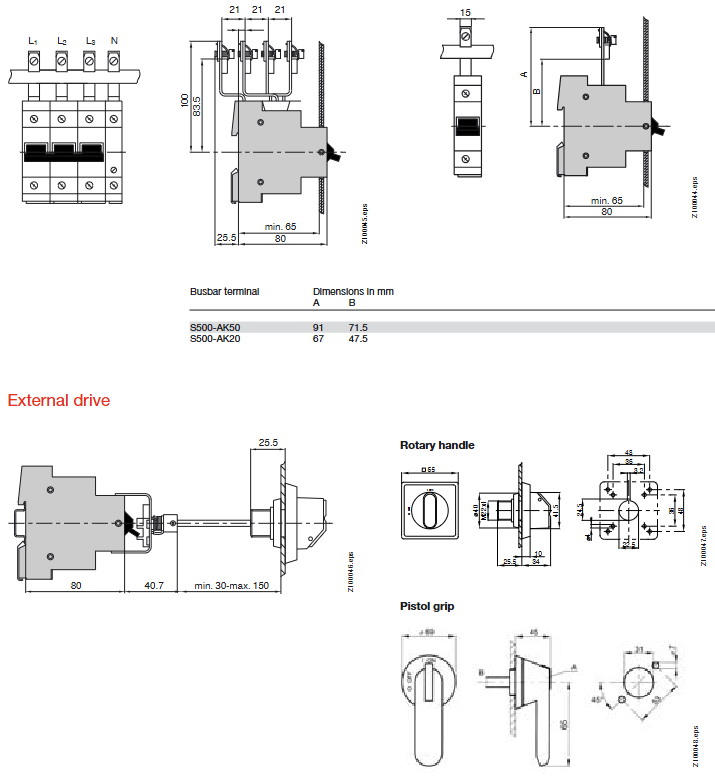

Including auxiliary contact HK, signal contact SK, locking device, rotary driver, handle, busbar terminal, end cover, insulation terminal, flush mounting frame, terminal cover, middleware, etc.

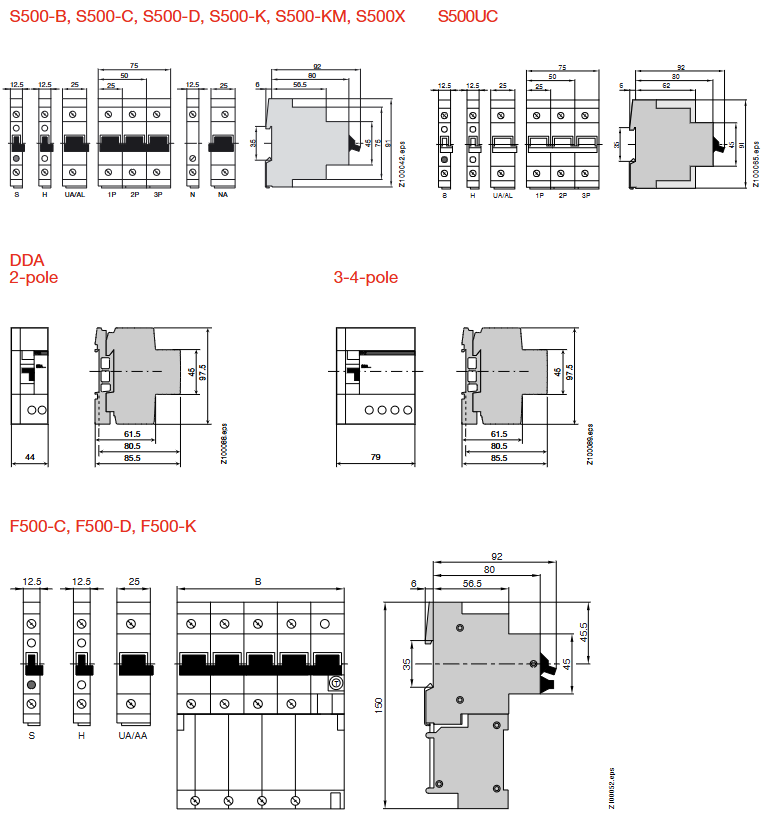

Installation and Dimensions

Installation method: S500 circuit breaker is designed for snap fit installation on standard 35mm rails.

Size: The size of products varies depending on the type and number of poles, for example, the 2-pole F502 series has a width of 75mm, the 3-pole F503 series has a width of 100mm, and the 4-pole F504 series has a width of 125mm.

Safety distance: There are specific safety distance requirements between grounding components, insulation covers or wiring pipelines, and exposed live parts.

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor

- SHINKAWA

- Other Brands