Kollmorgen S700 series digital servo amplifier

Kollmorgen S700 series digital servo amplifier

Basic Information

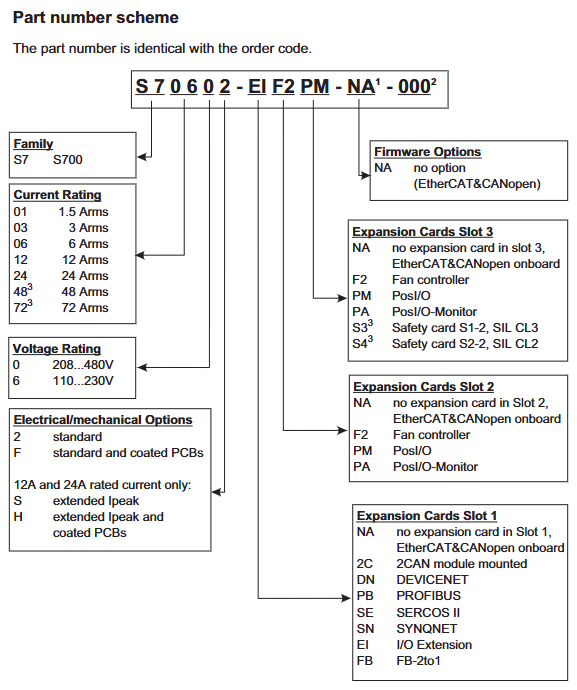

Core positioning: The S700 series is a high-performance digital servo amplifier that supports 208-480VAC three-phase input (S7xx0 model) or 110-230VAC single/three-phase input (S7xx6 model), integrates CANopen and EtherCAT bus interfaces, and comes standard with dual channel STO (Safe Torque Off) function (up to SIL CL3/PLe level). Additional functions such as PROFIBUS, SERCOS, DeviceNet can be achieved through expansion cards. It is recommended to use it with Kollmorgen motors and direct connection to loads is prohibited for operation.

Version and hardware adaptation: The document corresponds to hardware version 02.20 and requires firmware version ≥ 5.18 (ND1/NDO data structure). The functional differences between different hardware versions mainly lie in DC bus parallel capability and memory compatibility (support for memory cards at 02.10 and above). For older versions (such as 00.20/01.21), reference should be made to the corresponding manual revision.

Core technical characteristics and classification of amplifiers

(1) General Technical Parameters

Category parameter item specification

Power characteristic input voltage S7xx0:3 × 208V-10%~3 × 480V+10% (50/60Hz); S7xx6:1×110V-10%~3×230V+10%(50/60Hz)

The maximum DC bus voltage is 900VDC (S7xx0) and 455VDC (S7xx6), with an undervoltage fault of 100VDC and an overvoltage fault of 900VDC (S7xx0)/455VDC (S7xx6)

Rated output current of 1.5-24ARMS (e.g. S70102 is 1.5ARMS, S72402 is 24ARMS), peak value of 4.5-72ARMS (lasting for 2 seconds)

Motor adaptation motor types: synchronous servo motor, asynchronous motor, DC motor, linear motor

Motor inductance range S7xx0 (320VDC bus): 50-200mH; S7xx6 (160VDC bus): 7-30mH

Feedback supports rotary transformers, SinCos encoders (EnDat 2.1/2.2, BiSS-C, HIPERFACE), incremental encoders (ROD), SSI encoders

Control characteristic switch frequency 8kHz (output stage)

Control cycle current loop 62.5 μ s, speed loop 62.5 μ s, position loop 250 μ s (optional 125 μ s)

Safety function dual channel STO (SIL CL3/PLe), supporting extended safety functions such as SS1/SS2/SOS/SLS (requires safety expansion card)

Environmental adaptability: Operating temperature range of 0-40 ℃ (rated working condition), with a reduction of 2.5%/℃ required for 40-55 ℃

Storage temperature -25-70 ℃

Humidity 95% relative humidity (no condensation)

Altitude ≤ 1000m (no downgrading), downgrading 1.5%/100m for 1000-2500m

Protection level IP20 (IEC 60529)

(2) Model classification and key parameters

The S700 series is divided into two sub series based on rated output current and input voltage, with the following differences in core parameters:

Subseries models rated output current (ARMS) peak output current (ARMS/2s) input voltage DC bus voltage (VDC) weight (kg) heat dissipation method

S7xx0 (three-phase input) S70102 1.5 4.5 3 × 208-480VAC 900 4.4 Forced air cooling

S70302 3 9 3 × 208-480VAC 900 4.4 forced air cooling

S70602 6 18 3 × 208-480VAC 900 4.4 forced air cooling

S71202/S7120S 12 24/30 3 × 208-480VAC 900 5.5 forced air cooling

S72402/S7240S 24 48/72 3 × 208-480VAC 900 5.5 forced air cooling

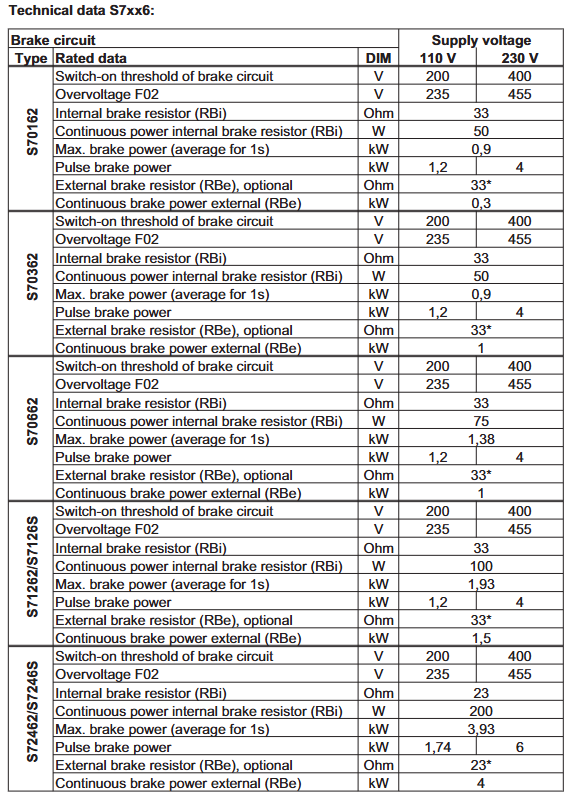

S7xx6 (single/three-phase input) S70162 1.5 4.5 1 × 110-230VAC/3 × 110-230VAC 455 4.4 Forced air cooling

S70362 3 9 1 × 110-230VAC/3 × 110-230VAC 455 4.4 Forced air cooling

S70662 6 18 1 × 110-230VAC/3 × 110-230VAC 455 4.4 Forced air cooling

S71262/S7126S 12 24/30 1 × 110-230VAC/3 × 110-230VAC 455 5.5 forced air cooling

S72462/S7246S 24 48/72 1 × 110-230VAC/3 × 110-230VAC 455 5.5 forced air cooling

(3) Optional configurations and expansion cards

Core Function Expansion

Security Expansion Card: Slot 3 can be installed with S3 (S1-2, SIL CL3/PLe) or S4 (S2-2, SIL CL2/PLd) security cards, supporting security functions such as SS1/SS2/SOS/SLS/SPLP. The S3 card also supports safety brake control (SBC) and brake testing (SBT).

Communication expansion card: Slot 1 supports PROFIBUS(DE-106712)、SERCOS(DE-90879)、DeviceNet(DE-103571)、SynqNet(DE-200073),Slot 2/3 Supports PosI/O (DE-200881) to expand high-precision I/O interfaces.

Feedback extension card: FB-2to1 (DE-201664) supports simultaneous connection of digital primary feedback and analog secondary feedback, solving compatibility issues with multiple feedback devices.

Heat dissipation optimization: Option F2 (Slot 2/3) is a controllable fan that automatically adjusts the speed based on temperature (55-75 ℃) and braking power (20-45W) to reduce noise (default fan noise is 43-65dB (A)).

Storage and Communication: Supports MMC/SD memory cards (DE-201257), which can store firmware and parameters, enabling fast configuration of multi axis systems; Standard RS232 (X6), CANopen (X6), EtherCAT (X7) interfaces, EtherCAT supports CAN over EtherCAT protocol and automatically detects bus type.

Installation and wiring specifications

(1) Mechanical installation requirements

Installation preparation

Installation surface: It should be made of conductive material (such as galvanized steel plate) with a flatness error of ≤ 0.1mm. It should be fixed with M5 hexagon socket screws (torque 0.7-0.8Nm). The installation size of S701-S712 is 345 × 70 × 243mm (H × W × D), and S724 is 348 × 100 × 243mm. A heat dissipation space of ≥ 25.4mm should be reserved around it. It is prohibited to install it under a heat source (such as a frequency converter).

Temperature control: If the ambient temperature exceeds 40 ℃, forced air cooling (wind speed ≥ 2m/s) should be added. When the temperature of the heat sink exceeds 80 ℃, the amplifier will overheat and shut down (fault F01). It is recommended to use the S724 model with a cold plate (heat dissipation area ≥ 0.1m ²).

Fan installation

S701-S712 fan: Pinch the long side of the fan housing and pull it down. When installing, align it with the green connector and push it into the buckle lock.

S724 fan: Pinch the short side of the fan housing and pull it down. When installing, make sure the connector is aligned with the socket and press it until the buckle is fixed. The fan has no independent wiring and can be powered through the internal connector.

(2) Electrical wiring specifications

Wiring safety and sequence

Power off operation, ensure capacitor discharge (≥ 8 minutes after power off, measure DC bus voltage<60V), all power cables (motor/power) and control cables (feedback/I/O) need to be separately shielded, and the shielding layer should be grounded 360 ° through the amplifier front panel or metal connector (low impedance).

The distance between power cables and control cables should be ≥ 200mm to avoid cross interference; When the length of the motor cable exceeds 25m, Kollmorgen 3YL/3YLN motor choke coils should be connected in series (such as S70102 with 4 × 1mm ² cable) to reduce leakage current and EMI interference.

Core interface definition

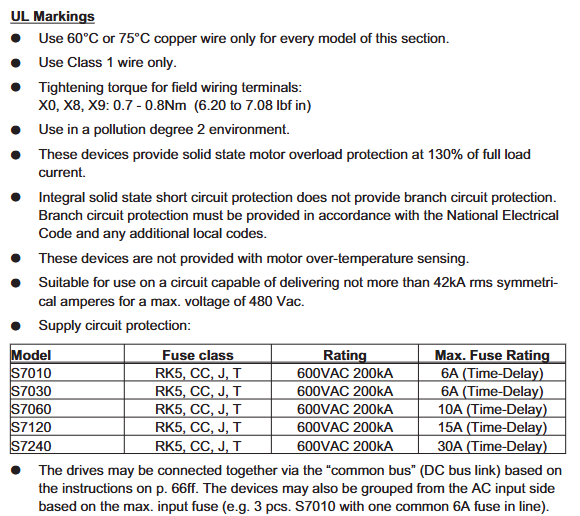

Power interface (X0): S7xx0 model L1/L2/L3 connected to three-phase live wire, PE connected to protective ground; S7xx6 single-phase connection L1/N, three-phase connection L1/L2/L3, PE wire section ≥ 10mm ² or dual PE wiring, external slow melting fuse needs to be configured (such as S70102 with 6A/600V, S72402 with 30A/600V).

Motor interface (X9): U2/V2/W2 is connected to the three-phase winding of the motor, PE is connected to the motor casing, BRAKE+/BRAKE - is connected to a 24V brake (only with a brake motor), the brake current is ≤ 2A, and a separate freewheeling component (such as a varistor) needs to be configured.

Safety interface (X4A/X4B): STO1 Enable (X4B/6) and STO2 Enable (X4A/3) are connected to external safety circuits (24V/33-40mA). In dual channel configuration, safety relay outputs need to be connected separately to ensure SIL CL3 level. When not in use, they need to be short circuited to+24V.

Feedback interface (X1/X2): X2 is the rotary transformer interface (9-pin SubD), R1/R2 is the reference signal, S1/S2/S3/S4 is the sine/cosine signal; X1 is an encoder interface (15 pin SubD) that supports protocols such as EnDat/BiSS/HIPERFACE. The FBTYPE parameter needs to be selected based on the feedback type (e.g. EnDat 2.2 is set to 32/34).

Typical wiring scheme

Three phase power supply (S70602): L1/L2/L3 connected to 3 × 400VAC, PE connected to cabinet ground, X0 terminal tightened with a torque of 0.7-0.8Nm, power supply side connected in series with 10A slow melting fuse (UL class RK5) to avoid damage from surge current.

Motor and brake (with brake motor): X9 terminal U2/V2/W2 is connected to the motor winding, BRAKE+is connected to 24V power supply, BRAKE - is connected to amplifier X9/1, the brake control wire uses shielded twisted pair (such as 2 × 0.75mm ²), the shielding layer is grounded at both ends, and additional mechanical braking is required for vertical axis applications (brake is only used for parking and frequent braking is prohibited).

STO safety circuit (dual channel): STO1 Enable (X4B/6) is connected to the normally closed contact of safety relay K1, STO2 Enable (X4A/3) is connected to the normally closed contact of safety relay K2, and the relay coil is controlled by the emergency stop button. When the emergency stop is triggered, the STO signal is disconnected, and the amplifier cuts off the motor torque (fault F27).

Security Features and System Configuration

(1) STO security function (core security feature)

Function definition and level

STO (Safe Torque Off) achieves no torque output of the motor by blocking the triggering pulse of the power transistor, which complies with EN 60204-1 stop category 0 (uncontrolled shutdown). The single channel configuration (STO1/STO2 series) reaches SIL CL2/PLd, and the dual channel+cycle test (safety controller monitoring feedback signal) reaches SIL CL3/PLe. The PFH_D is 1.04E-09 1/h, and the MTBF is 20 years.

Wiring and Testing

Single channel wiring: STO1 Enable and STO2 Enable are connected in series and then connected to a safety relay output. The reference ground is XGND (X4B/5), with an input voltage of 20-30VDC and a current of 33-40mA. When disconnected, the amplifier displays "- S -" and the motor has no torque.

Functional testing:

When the motor is stationary (the enable signal is valid), disconnect the STO input, the amplifier should immediately cut off the torque, display fault F27, and the BTB/RTO contact (X3B/14-15) is disconnected.

Reset STO input, use Fault Reset input (X3A/18) or software reset to restore the amplifier to normal state, with a test cycle of ≤ 8 hours (SIL CL3 requirement).

(2) System configuration (software and hardware settings)

Software Configuration (DRIVE GUI. EXE)

Installation and Connection: Supports Windows 2000/XP/Vista/7, connects PC and amplifier X6 interface through RS232 cable (P7S2-232-9D), baud rate 38400bps, data bit 8, even check, stop bit 1, software automatically recognizes amplifier model and firmware version.

Core configuration module:

Motor configuration: Select the motor model (such as AKM series) from the database, or manually input parameters such as rated current, torque constant, inductance, etc., and perform the "Motor Probe" to detect the motor inductance and optimize the current loop gain.

Security configuration: The STO function requires setting the STO Status output (such as X3A/6) and associating it with the security controller through the ASCII command OxMODE70 to achieve periodic testing; The security card S3/S4 needs to be configured with SS1 activation signal (X30/1) and reset signal (X30/20) to ensure the correct triggering timing of the security function.

Sports configuration: Set the electronic gear ratio for the position ring (e.g. set PGEAR1=2 and PGEAR0=1 for a 1:2 gearbox), gain for the speed ring (Kp=0.5-2.0, Tn=0.01-0.1s), and automatically optimize control parameters through "Autotuning" to reduce tracking errors (fault F03).

Hardware switch configuration

Address and baud rate: Set the CANopen station address (1-99) and baud rate (10-1000kbit/s) through the amplifier front-end buttons. After setting, restart the 24V power supply to take effect. The baud rate encoding is as follows: "25" corresponds to 250kbit/s, and "50" corresponds to 500kbit/s.

Expansion card recognition: After inserting the expansion card into Slot 1/2/3, the amplifier will automatically recognize it when powered on. The function can be configured through the DRIVE GUI "Expansion Card" interface (such as setting the PROFIBUS address to 3 and the baud rate to 1.5Mbit/s). If the expansion card is not recognized, it is necessary to check whether it is installed properly (card buckle locking).

Troubleshooting and Maintenance

1、 Troubleshooting System

(1) Fault diagnosis tools and processes

Front end LED display diagnosis

The 3-character LED display on the front end of the amplifier is the core fault indicator unit, and different states correspond to different fault types:

Red flashing: Fault code (such as F01-F32), it is necessary to locate the problem based on the fault table, and the number of flashes corresponds to the fault number (such as flashing once is F01).

Yellow constantly on: EOT (end of travel) input latch (such as n10/n11), the motor needs to be moved in reverse to disengage from the limit sensor.

Red constantly on: FLASH memory verification error (F09), firmware needs to be re downloaded (via memory card or PC software).

- S - "display: STO function activated (STO1/STO2 Enable is 0V), check the safety circuit wiring or safety relay status.

Troubleshooting process

Preliminary inspection: Confirm if the power supply voltage (X0 terminal), 24V auxiliary power supply (X4A), and STO signal (X4A/3/X4B/6) are normal, disconnect the load to test the motor for independent operation, and eliminate mechanical jamming.

Parameter verification: Read parameters (such as motor current, speed, and bus voltage) through DRIVE GUI software, confirm that I2/rms/I2 peak does not exceed the rated value, and provide feedback parameters (FBTYPE, ENCVON) that match the actual feedback type.

Hardware testing: Measure the resistance of the motor winding (three-phase balance, deviation ≤ 5%), feedback cable continuity (if there is no open circuit between terminal X1 A+/A -), and check the temperature of the power module (triggering F01 when the heat sink exceeds 80 ℃).

(2) Common fault codes and solutions

Fault code, fault description, possible causes, and solutions

F01 heat sink overheating: 1. The ambient temperature exceeds 40 ℃; 2. Fan malfunction; 3. The load duty cycle is too high. 1. Increase forced air cooling (wind speed ≥ 2m/s); 2. Replace the fan (S701-S712 fan model DE-200454); 3. Reduce the frequency of motion or increase the motor model

F02 DC bus overvoltage: 1. Input voltage exceeds the rated value (such as S7xx0 exceeding 480VAC); 2. Excessive braking power (failure to consume regenerative energy in a timely manner); 3. External braking resistor not connected. 1. Check the grid voltage and install a three-phase stabilized power supply; 2. Increase the power of the external braking resistor (such as S72402 with a 23 Ω/4kW resistor); 3. Connect the external braking resistor to the X8 terminal (remove the X8/3-X8/4 shorting bar)

F03 tracking error exceeds tolerance

1. Position loop gain (Kp) is too low; 2. The load inertia ratio exceeds the set value; 3. The motor current limit is too small. 1. Increase Kp through DRIVE GUI (such as adjusting from 0.5 to 1.0); 2. Reset the load inertia ratio (S2-5~S2-7 switches or software parameters); 3. Increase I2/RMS/I2 peak (not exceeding the rated value of the motor)

F04 feedback fault 1. Feedback cable breakage/short circuit; 2. Feedback equipment damage (such as encoder); 3. FBTYPE parameter setting error: 1. Use a multimeter to measure the continuity of the feedback cable (e.g. X1 terminal A+/A - resistance should be ≥ 1k Ω); 2. Replace feedback devices (such as EnDat encoder ECN1313); 3. Match FBTYPE with feedback type (e.g. BiSS-C set to 33)

F05 DC bus undervoltage 1. Input voltage too low (such as S7xx0 below 208VAC); 2. Power phase loss (S7xx0 three-phase phase loss); 3. Soft start circuit fault: 1. Check the grid voltage and eliminate the line voltage drop; 2. Measure the three-phase voltage of X0 terminal (deviation ≤ 5%); 3. Replace the soft start relay (located on the power board inside the amplifier)

F06 motor overheating 1. Motor PTC thermistor triggered; 2. The motor load exceeds the rated torque; 3. Poor heat dissipation of the motor: 1. Measure the PTC resistor of the motor (normal temperature ≤ 550 Ω, overheating ≥ 1330 Ω) and replace the thermistor; 2. Reduce the load or increase the motor model; 3. Clean the motor cooling channel and increase fan cooling

F27 STO operation fault 1. Simultaneous activation of STO signal and ENABLE signal; 2. STO circuit disconnection; 3. Safety card failure (S3/S4) 1. Ensure that the motor has stopped (speed ≤ 5rpm) before STO activation; 2. Check the wiring of X4A/3/X4B/6 (24V voltage is normal); 3. Reset the security card (power off for 8 minutes and restart)

(3) Special fault handling

Occasional faults caused by EMI interference (such as F17/A/D conversion errors)

Reason: The power cable and feedback cable are wired in parallel, with poor shielding grounding and large leakage current.

Solution:

The distance between the motor cable and the feedback cable should be ≥ 200mm, and they should be perpendicular at a 90 ° angle when crossing;

The feedback cable uses twisted pair shielded wire (such as Belden 82509, capacitance ≤ 120pF/m), and the shielding layer is grounded 360 ° through the amplifier front-end panel;

Connect a Corcom 6EQ1 power filter in series at the power input to reduce conducted interference.

DC bus parallel fault in multi axis system (such as F19/DC bus crash)

Reason: Different hardware versions of amplifiers are connected in parallel (such as mixing 01.21 and 02.20), and the DC bus cable is too long (exceeding 200mm).

Solution:

Ensure that the hardware versions of the parallel amplifiers are consistent (such as 02.20), and use 6mm ² shielded cables with a length of ≤ 200mm for the DC bus;

Connect KCM capacitor modules (such as KCM-S200, with a storage capacity of 1600Ws) in parallel at both ends of the DC bus to absorb regenerative energy;

Configure DC bus fuses (such as 30A/900VDC) for every group of 3 amplifiers to avoid individual failures affecting the overall system.

2、 Daily maintenance and lifecycle management

(1) Regular maintenance project (recommended cycle)

Standard requirements for maintenance project cycle operation content

Cooling system inspection: 1. Clean the dust on the fan filter every month; 2. Check the fan speed (S701 fan speed ≥ 2500rpm); 3. Measure the temperature of the heat sink. 1. There is no obvious dust accumulation on the filter screen; 2. The fan has no abnormal noise and the speed deviation is ≤ 10%; 3. The temperature of the heat sink during operation is ≤ 75 ℃

Quarterly inspection of wiring terminals: 1. Tighten the X0/X8/X9 terminal screws (torque 0.7-0.8Nm); 2. Check if the grounding of the cable shielding layer is loose; 3. Measure the conductivity resistance of the PE wire. 1. The terminals are not loose or oxidized; 2. The grounding resistance of the shielding layer is ≤ 0.1 Ω; 3. PE wire conductivity resistance ≤ 1 Ω

Feedback system verification every six months: 1. Read the feedback signal quality through DRIVE GUI (such as SinCos signal amplitude ≥ 1Vpp); 2. Test the forward and reverse positioning accuracy of the motor. 1. Signal amplitude deviation ≤ 10%; 2. Positioning error ≤ 0.1 ° (motor unloaded)

Monthly safety function testing: 1. Trigger the STO function and check if the motor has no torque output; 2. Test the SS1 function of the safety card S3/S4 (controlled motor shutdown after triggering). 1. The motor can rotate freely after STO activation; 2. After SS1 is triggered, the motor stops on an emergency stop ramp (≤ 1s from rated speed to 0)

(2) Long term storage and capacitor maintenance

Storage requirements

Environment: Temperature -25~55 ℃, humidity 5%~95% (no condensation), stacking height ≤ 8 boxes, away from corrosive gases/dust.

Over 1 year storage: The DC bus capacitor needs to be "reshaped" - disconnect all wiring, apply single-phase 230VAC to the X0 terminal for 30 minutes, to avoid capacitor capacity decay.

Capacitor lifespan management

Under normal operating conditions, the lifespan of DC bus capacitors is about 5 years (in a 40 ℃ environment), and the lifespan is halved for every 10 ℃ increase in ambient temperature.

Detection method: Use DRIVE GUI to read the DC bus voltage fluctuation (voltage ripple should be ≤ 5% under no-load), and replace the capacitor module (model KCM-E200) when the fluctuation exceeds 10%.

(3) Repair and scrapping process

Maintenance Request

The faulty amplifier needs to be repaired through the official channels of Kollmorgen: fill out the repair application form (Appendix 10.3 of the manual), indicate the product model, serial number, and fault phenomenon, and send it to customer service in Europe (fax+49 (0) 2102-9394-3444) or China (fax+86-21-6128-9877).

Repair scope: Only authorized repair centers can disassemble amplifiers (unauthorized disassembly may cause warranty failure). Common repair components include power modules (IGBT), fans, and power boards.

scrap disposal

According to the requirements of the WEEE Directive (2002/96/EC), professional electronic waste disposal institutions are responsible for recycling, with a focus on separating metal casings, PCB boards, capacitors (including electrolytes), and prohibiting arbitrary disposal.

Before scrapping, it is necessary to clear the storage data (execute "Restore Default Configuration" through DRIVE GUI) to avoid parameter leakage.

3、 Preventive maintenance recommendations

environmental control

Install temperature sensors (such as PT100) inside the control cabinet. When the temperature exceeds 40 ℃, an alarm will be triggered and the linked axial fan (such as 24V/0.5A) will start;

Install a dehumidifier when the humidity exceeds 90% to prevent the PCB board from getting damp and short circuiting.

Software monitoring

Set up "maintenance reminders" through DRIVE GUI software (such as reminding to check the fan after running for 2000 hours), regularly backup parameters (saved as. par files), and avoid parameter loss;

Enable the "Fault Log" function (ASCII command LOGENABLE=1) to automatically record the time, current, and speed of the fault occurrence, making it easy to trace the root cause of the fault.

Spare Parts Management

It is recommended to reserve 1-2 sets of key spare parts (such as fans, power filters, and braking resistors), and the spare parts model should match the amplifier (such as S70102 fan model DE-200454, braking resistor model BAR-23-4kW).

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor

- SHINKAWA

- Other Brands