Comprehensive Analysis and Selection Guide for Siemens SICAM 8 Substation Automation Platform

As a leader in the field of energy automation, Siemens has launched the SICAM 8 power automation platform with its pioneering contributions and long-term technological accumulation in the development of the IEC 61850 standard. This platform is not a simple stack of single products or devices, but a comprehensive solution that integrates hardware, software, communication, security, and application ecology. It aims to provide a flexible, scalable, highly secure, and future oriented automation foundation for various application scenarios, from high-voltage transmission to low-voltage distribution, from traditional power stations to new energy stations, from urban power grids to industrial parks.

Siemens SICAM 8 Substation Automation Platform: Building an Intelligent, Safe, and Future Power Grid Core

Introduction: Evolution of Power Grid and New Paradigm of Automation

The modern power system is undergoing a profound transformation from static stable operation to dynamic flexible scheduling. The large-scale integration of renewable energy, the popularization of electric vehicle charging infrastructure, and the demand for two-way interaction on the user side pose unprecedented challenges to the reliability, observability, controllability, and safety of the power grid. In this context, substation automation technology has evolved from an auxiliary support role to a core pillar that ensures the safe, economical, and efficient operation of the power grid. It is not only the foundation for data collection and device monitoring, but also a key platform for supporting advanced applications such as self-healing, optimization, and interaction of smart grids.

As a leader in the field of energy automation, Siemens has launched the SICAM 8 power automation platform with its pioneering contributions and long-term technological accumulation in the development of the IEC 61850 standard. This platform is not a simple stack of single products or devices, but a comprehensive solution that integrates hardware, software, communication, security, and application ecology. It aims to provide a flexible, scalable, highly secure, and future oriented automation foundation for various application scenarios, from high-voltage transmission to low-voltage distribution, from traditional power stations to new energy stations, from urban power grids to industrial parks.

SICAM 8 Platform Core Architecture: Exquisite Balance between Integration and Modularity

The SICAM 8 platform adopts the innovative concept of "integrated platform, modular deployment". Its core structure is clearly divided into three levels:

SICAM 8 Core: As the cornerstone of security and trust for the platform, it is responsible for unified certificate management, application lifecycle management, and core security functions, providing a consistent and internationally compliant security foundation for the entire platform.

SICAM 8 Software: Includes a range of applications that can be deployed independently or in combination:

SICAM S8000: As the core software RTU (Remote Terminal Unit) and software PLC (Programmable Logic Controller), it provides functions such as protocol conversion, data centralization, and logic control, supports full virtualization deployment, and achieves complete decoupling of hardware and software.

SICAM HMI: A localized human-machine interface solution for monitoring and operating small and medium-sized sites, integrated with SICAM Device Manager to reduce learning and maintenance costs.

SICAM WEB: A device configuration, diagnosis, and monitoring tool based on a web browser, greatly simplifying on-site debugging and maintenance work.

SICAM GridPass: A professional certificate management system (PKI) that provides automated certificate issuance, update, and revocation management for secure communication (such as TLS) under the IEC 62351 standard.

Advanced applications: such as SICAM DLM (Dynamic Load Management) for electric vehicle charging load coordination; SICAM Self Optimizing Grid enables advanced applications such as fault self-healing and voltage optimization in distribution networks.

SICAM 8 Hardware: Based on the SICAM A8000 series modular equipment family, supplemented by certified industrial PCs (IPC). The hardware platform is based on Linux system and provides a full range of products from compact RTUs to high-performance station control computers.

This architecture ensures that users can smoothly evolve from "solving simple problems with a single device" to "processing complex tasks with a distributed system", protecting initial investments and calmly responding to future demand changes.

Hardware cornerstone: Excellent flexibility and robustness of SICAM A8000 series

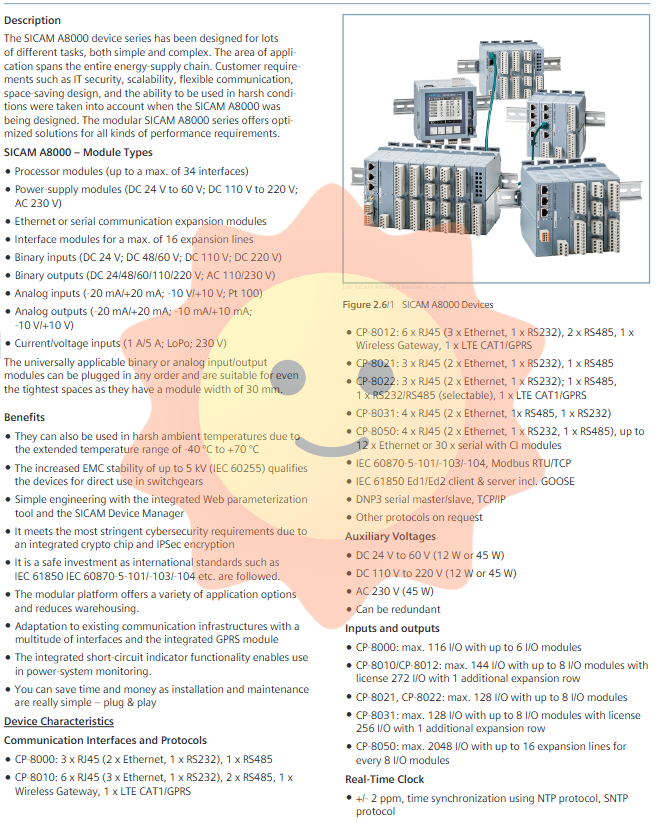

The SICAM A8000 series is the backbone of the platform's physical layer, and its design fully considers the stringent requirements of power applications:

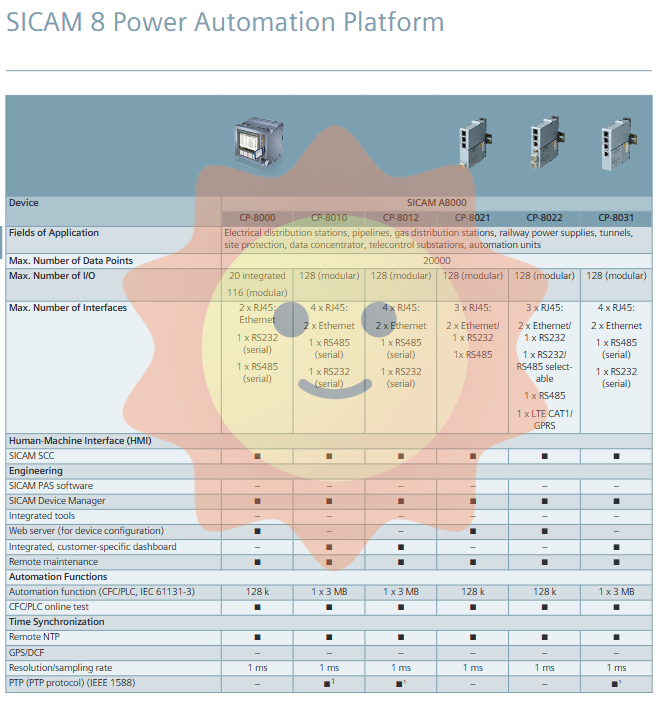

Ultimate modularity and scalability: The series includes a full range of products from compact integrated devices such as CP-8000/8021/8022 to high-performance modular processors such as CP-8031/CP-8050. The I/O modules (digital input/output, analog input/output, AC sampling) have a uniform width of 30mm and can be plugged in any order. Remote distributed deployment of I/O can be achieved through the expansion module (CI-853x). This design enables the system configuration to accurately match point requirements, avoid waste, and support convenient expansion in the future.

Strong environmental adaptability: The working temperature range can reach -40 ° C to+70 ° C, and some models can meet the requirements of -25 ° C to+70 ° C. With a protection level of up to IP40 and enhanced EMC immunity (up to 5kV), the equipment can be directly installed in harsh environments such as switchgear without the need for additional control cabinets.

Rich communication and protocol support: Native support for mainstream protocols such as IEC 61850 (Ed1/Ed2, including GOOSE), IEC 60870-5-101/103/104, DNP3, Modbus, PROFINET IO, etc., and can also support top-level network redundancy technologies such as PRP (parallel redundancy protocol) and HSR (high availability seamless ring network) that comply with IEC 62439-3 through additional modules, achieving zero interruption switching of communication and meeting the needs of critical protection and control applications.

Future oriented network security embedding: Adhering to the Security by Design process from the beginning of design and complying with the IEC 62443-4-1 standard. The device integrates encryption chips, supports IPSec and TLS encrypted communication, and has a complete set of security functions such as role-based access control (RBAC), security event logging (Syslog), firmware signing, etc., meeting global security standards such as BDEW white papers and NERC CIP.

Software Soul: Collaborative Empowerment of SICAM S8000 and Engineering Tools

The software defines the upper limit of the platform's intelligence and flexibility.

SICAM S8000: Hardware independent virtualized RTU: It marks a paradigm shift for substation controllers from dedicated hardware devices to standardized software services. S8000 can be deployed as a software package on certified industrial PCs or run entirely in virtualization environments such as VMware and Hyper-V. Its advantages are significant:

Hardware independence: Users can freely choose or replace the underlying server hardware, avoiding vendor lock-in and utilizing technological advancements in the IT field to reduce costs.

Rapid deployment and testing: Virtual machines can be used to build a "digital twin" testing environment, accelerating factory acceptance testing (FAT), software updates, and engineering validation processes.

Function integration and expansion: Multiple applications such as RTU, HMI, and archiving can be integrated on a single runtime, and the SIAPP (SICAM Application) container supports rapid integration of third-party or custom dedicated algorithms.

Unified engineering environment: SICAM Device Manager is the core tool for configuring the entire A8000 series and S8000 software. It provides an intuitive graphical interface that supports IEC 61850 engineering, CFC/PLC logic programming (compliant with IEC 61131-3), SVG graphic dashboard editing, and other functions. Seamless compatibility with SICAM WEB ensures consistency between office engineering and on-site debugging.

Advanced Monitoring and Diagnostic Kit:

SICAM PAS/PQS: As a central station control and power quality management system for large substations or distributed systems, it is responsible for large-scale data collection, processing, archiving, automated task execution, and communication with higher-level dispatch centers.

SICAM SCC: Based on SIMATIC WinCC, the SCADA/HMI system provides professional substation process visualization, control, alarm management, and archiving functions, supporting deep integration with SICAM PAS and various protection devices.

SICAM PQ Analyzer&SIGRA: a professional tool dedicated to power quality analysis and fault recording. PQ Analyzer can collect, evaluate, and generate reports on monitoring data from PQ devices across the entire network, helping operation and maintenance personnel locate power quality issues. SIGRA is used for in-depth analysis of fault recording files in COMTRADE format, quickly locating the cause of system faults through various views (timing diagrams, vector diagrams, harmonic analysis, etc.).

The cybersecurity gene that runs through the entire process

In today's unprecedented level of digitization and networking, network security is the lifeline of substation automation. The Siemens SICAM 8 platform considers security as an inherent attribute rather than an additional feature:

Security development process: Product development follows the highest maturity level (ML4) of IEC 62443-4-1 (Security Development Lifecycle), incorporating security considerations at every stage from requirement analysis, design, coding to testing.

Defense in depth system:

Physical and Access Security: Role Based Access Control (RBAC), Certificate Authentication, Support for IEEE 802.1X Network Access Control.

Communication security: TLS (for IEC 61850/60870-5-104/DNP3) and IPSec are widely used to encrypt and protect the integrity of transmitted data.

Device integrity: using signed firmware to prevent unauthorized software tampering; Integrate hardware encryption chips to protect key security.

Monitoring and auditing: Centralized security event logs (Syslogs) and asset information monitoring to ensure traceability of all operations.

Centralized Certificate Management (SICAM GridPass): simplifies the complexity of issuing, distributing, updating, and revoking digital certificates in large-scale deployments, making certificate based secure communication feasible and efficient in practice.

Wide range of application scenarios and significant value

The application footprint of SICAM 8 platform covers the entire power value chain:

Traditional substation automation: as a station control system for high and ultra-high voltage substations (such as CP-8050), or compact RTUs for medium and low voltage distribution stations (such as CP-8031/8022).

Distribution Network Automation (DA) and Self Optimization: By combining edge devices such as SICAM EGS (Enhanced Grid Sensors), feeder automation (FA), fault location, isolation and recovery (FLISR), as well as static/dynamic self-healing and wide area voltage control supported by SICAM Self Optimizing Grid applications, the reliability and quality of power supply are greatly improved.

New energy integration: As a monitoring and power control gateway for photovoltaic power plants and wind farms (onshore/offshore), it achieves controllable, observable, and adjustable connection with the power grid dispatch center.

Electric vehicle charging infrastructure management: Dynamically manage the load of charging pile groups through SICAM DLM, avoid transformer overload, maximize the utilization of existing distribution capacity, and delay investment in power grid upgrades.

Industry and Infrastructure: Provide reliable monitoring and automation solutions for railway traction power supply, large factories and mines, data centers, oil and gas pipelines, etc.

The core value it brings lies in: reducing total investment and lifecycle costs through standardization and modularization; Protecting technology investments through openness and scalability; Enhance the reliability, efficiency, and resilience of power grid operations through built-in advanced features and security; Reduce reliance on professional skills and operational complexity through unified engineering tools.

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor

- SHINKAWA