Technical Analysis and Professional Operation Guide for SIEMENS 1FK6 Servo Motor

Technical Analysis and Professional Operation Guide for SIEMENS 1FK6 Servo Motor

The Siemens 1FK6 series three-phase servo motor, as a representative of early high-performance servo drive solutions, is still widely used in machine tools, automated production lines, robots, and precision positioning systems. This series of motors adopts permanent magnet synchronous technology, which has the characteristics of high dynamic response, precise control, and reliable operation. This article will be based on its official multilingual operation manual, systematically analyzing its technical parameters, installation specifications, electrical connections, startup process, and maintenance points, providing comprehensive professional references for engineers and technicians.

Product Overview and Safety Standards

The 1FK6 series servo motor is a permanent magnet excitation three-phase synchronous motor, suitable for motor controlled indirect AC frequency converters with sinusoidal current control mode. The motor is designed to drive and position machine tools, production line equipment, robots, and handling devices, and is not suitable for explosive hazardous areas (unless otherwise specified).

Safety regulations are particularly important, and safety warnings in the manual must be read and followed before operation, including:

Electrical safety: It must be operated by professionals with electrical qualifications, following the EN 50110-1 standard.

High temperature warning: The surface temperature of the motor can reach up to 140 ° C, and it is necessary to prevent contact and ensure heat dissipation.

Magnetic field risk: The rotor contains strong permanent magnets, which have strong attraction to ferromagnetic objects and may affect pacemakers or damage electronic storage media.

Mechanical safety: Suitable lifting tools must be used during transportation and installation, and the maximum weight of the motor can reach 50kg.

Detailed explanation of technical parameters

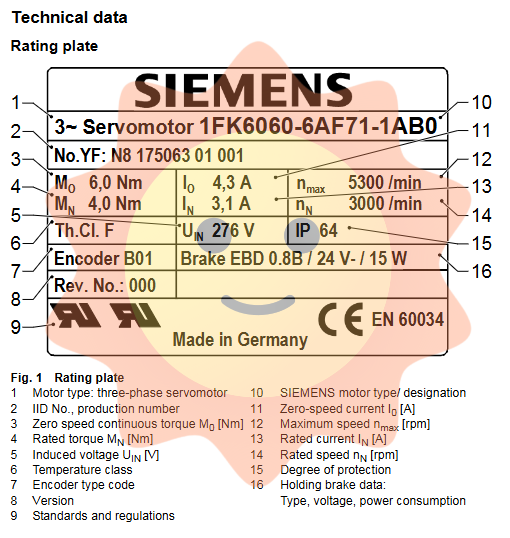

3.1 Interpretation of nameplate information

The motor nameplate contains key operating data, such as:

Motor type: Three phase servo motor

Zero speed continuous torque

M0M 0

Rated torque

M N M N

maximum speed

n max n max

Rated speed n N n N

rated current I N I N

Zero speed current I0I 0

Insulation level and protection level (IP64)

Encoder type, brake data (if applicable)

3.2 Main Characteristics

Structural form: IM B5 (IM V1, IM V3)

Cooling method: self cooling

Noise level: Approximately 55-70 dB (A), depending on the model

Thermal protection: KTY84 temperature sensor is built-in in the stator winding

Bearing: Rolling bearing, lifelong lubrication, designed for a lifespan of approximately 20000 hours

Environmental temperature: -15 ° C to+40 ° C, exceeding it requires derating for use

Installation altitude: ≤ 1000 meters, higher altitudes require power factor correction

Encoder system: supports incremental, absolute value (EnDat), rotary transformers, etc

Options and extensions

Low inertia series: suitable for high dynamic response scenarios

High protection level: optional IP65, driver end flange can reach IP67

Brake: Closed circuit current holding brake, 24 V DC power supply

Planetary gearbox: can be installed together

Shaft end form: can be balanced with keyway and half key

Installation and mechanical assembly

4.1 Transportation and Storage

Use lifting rings or straps for vertical lifting to avoid impact.

The storage environment should be dry, low dust, and low vibration(veff<zero point two mm two v eff<0.2mm two).

4.2 Installation points

Remove the anti-corrosion agent from the shaft end before installation.

Ensure sufficient heat dissipation space, it is recommended to leave at least 100mm gap on three sides.

The flange installation needs to be evenly tightened, using grade 8.8 or above hexagon socket bolts.

Do not apply axial force on motors with brakes.

After installation, manually rotate the output component and check for any abnormal friction.

Vibration and Balance

The motor with keyway has been balanced with half key when it leaves the factory.

The system vibration is affected by output components, installation alignment, and external vibrations, and the vibration acceleration after assembly shall not exceed 5g.

Installation of output components

Use appropriate tools to install couplings, gears, pulleys, etc.

Heatable components for installation, use gaskets to protect the center hole of the shaft end during disassembly.

If necessary, perform overall dynamic balancing according to ISO1940 standard.

Electrical connection and wiring specifications

5.1 Important precautions

It is strictly prohibited to directly connect to the three-phase power grid, and it must be driven by a matching frequency converter.

The phase sequence must be correct.

Encoders and temperature sensors are static sensitive components and require anti-static measures during operation.

Recommend using Siemens pre installed cables (not standard) to improve installation efficiency and safety.

Wiring requirements

The power and signal lines need to be shielded and comply with EMC specifications.

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor

- SHINKAWA