Technical Analysis and Professional Operation Guide for SIEMENS 1FK6 Servo Motor

The inside of the plug should be clean and free of moisture, and the wire ends should not be exposed.

A stress relief device is required to prevent the plug from being subjected to stress.

The encoder plug needs to be aligned with the card slot and manually tightened.

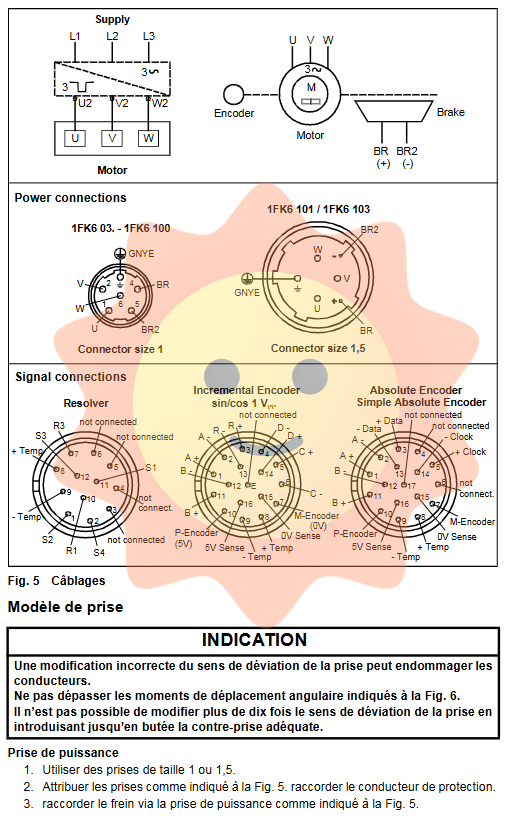

5.2 Plug specifications and torque

Power plug size: 1 or 1.5

Signal plug compatible with encoder type

Maximum allowable torsional moment:

Size 1:12 Nm

Size 1.5:20 Nm

The direction of the plug outlet can be adjusted up to 10 times, and a matching socket is required.

Startup and Debugging Process

6.1 Pre startup inspection

Confirm that all wiring is correct and plugs are securely locked.

The motor protection device has been activated.

Drive without obstruction or external hazards.

The motor is not damaged during transportation.

The key in the keyway has been secured to prevent detachment.

6.2 Startup steps

Release the brake (if applicable).

Test the brake function and power on to check if the rotor rotates freely.

Check the installation and alignment of the motor.

Confirm that the output components (such as belt tension) are set correctly.

Check the power and signal connections.

Test the functionality of auxiliary equipment.

Ensure that there are protective covers for moving and live parts.

Start the system according to the frequency converter manual.

Monitor the speed not exceeding n max n max.

Note that the built-in temperature sensor cannot cover all fault situations.

Fault diagnosis and handling

Common faults and handling suggestions:

Possible causes and solutions for the fault phenomenon

Check for poor shielding and grounding of motors or encoder cables with unstable operation

Excessive vibration results in unbalanced or poorly aligned output components. Rebalance or centering is necessary

Contact the manufacturer for repair if abnormal noise or foreign objects enter or bearings are damaged

Motor overheating (>140 ° C), excessive load or poor heat dissipation. Check the load, clean the surface, and improve ventilation

If it cannot be resolved, Siemens service or authorized repair center should be contacted.

Maintenance, inspection, and scrapping

Cleaning: Regularly clean the surface according to the degree of pollution to ensure heat dissipation.

Bearing lifespan: approximately 20000 hours (lifelong lubrication with grease).

Shaft seal life: about 5000 hours under oil lubrication.

Encoder recalibration: The encoder system needs to be recalibrated after each motor disassembly.

Scrap disposal: In accordance with local electronic waste regulations, the motor can be recycled or returned to the manufacturer.

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor

- SHINKAWA