SIEMENS CP 5613 A2/CP 5614 A2 Communication Processor

SIEMENS CP 5613 A2 and CP 5614 A2 PROFIBUS Communication Processor Comprehensive Technical Guide

In industrial automation and communication systems, reliable network connections are the cornerstone of ensuring efficient and stable data transmission. The CP 5613 A2 and CP 5614 A2 communication processors launched by Siemens are designed specifically for integrating personal computers (PCs) or programming devices (PG) into PROFIBUS networks. They are key components for building distributed control systems (DCS) and implementing device level data acquisition. This article provides a comprehensive and in-depth analysis of these two communication processors based on official operating instructions (C79000-G8976-C301-02, 12/2012), covering product overview, installation configuration, technical specifications, and compliance certification. The aim is to provide a detailed and reliable reference manual for automation engineers, system integrators, and technical maintenance personnel.

Product Overview and Components

CP 5613 A2 and CP 5614 A2 belong to the SIMATIC NET communication processor family and use the short PCI card format, suitable for industrial PCs or workstations with standard PCI or PCI-X slots. The standard supply includes the communication processor itself, SIMATIC NET software CD, and license certificate. Users need to verify the integrity of the packaging upon receipt.

The core function of both processors is to provide an efficient PROFIBUS interface, support a full range of data transmission rates from 9.6 kbps to 12 Mbps, and have the ability to automatically adapt to bus clocks (up to 66 MHz). The main difference lies in the number of interfaces and working mode:

CP 5613 A2: Equipped with a PROFIBUS interface, it can operate as a DP master or DP slave. As the master station, its DP Base function optimizes high-speed access to up to 124 DP slave stations and ensures data consistency.

CP 5614 A2: In addition to all the functions of CP 5613 A2, an additional PROFIBUS interface is provided. This enables it to operate simultaneously as a DP master on one interface and as a DP slave on another interface, providing a hardware foundation for building layered or redundant PROFIBUS network architectures. The data transmission mechanism controlled by its program supports flexible exchange of data between the master and slave modules.

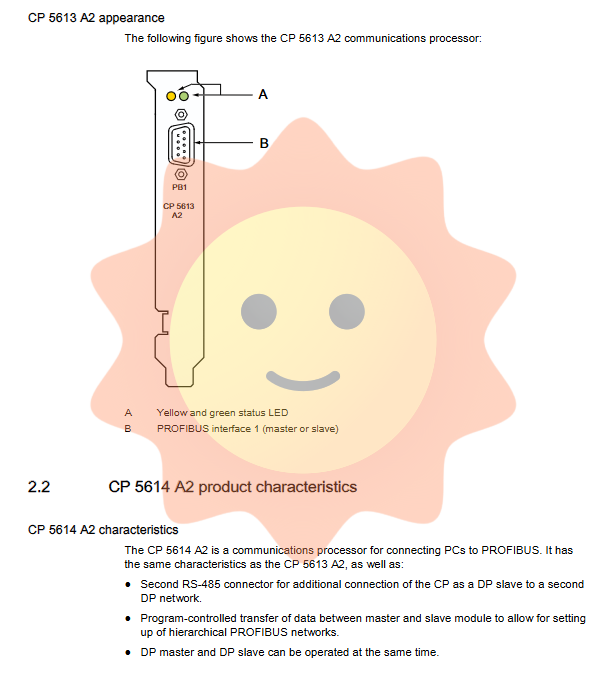

On the appearance of the device, CP 5613 A2 is equipped with a yellow/green status LED and a PROFIBUS interface (D-Sub 9-pin female head). CP 5614 A2 is equipped with two interfaces, labeled as master interface and slave interface, sharing the same set of status LEDs. Its pin definitions comply with the standard PROFIBUS RS-485 specification, where pins 3 and 8 are signal lines (B and A) and provide a set of isolated 5V/90mA power outputs (pins 5 and 6) that can be used to power external terminal resistors or simple devices.

Safety regulations and requirements for qualified personnel

Siemens emphasizes the importance of safety and standardized operations at the beginning of the document. The warning notification system is divided into four levels:

Danger: Failure to comply may result in death or serious personal injury.

Warning: Failure to comply may result in death or serious personal injury.

Caution: Failure to comply may result in minor personal injury.

Attention: Failure to comply may result in property damage.

All warnings related to personal safety are accompanied by safety warning symbols. Before installation and operation, all relevant warnings and safety instructions must be carefully read and followed.

Only qualified personnel are allowed to operate. Qualified personnel refer to professionals who, based on their training and experience, are able to identify risks and avoid potential hazards. In addition, Siemens products must be used correctly, i.e. only for applications described in the catalog and related technical documents. If using third-party products, Siemens recommendation or approval is required. Proper transportation, storage, installation, debugging, operation, and maintenance, as well as compliance with permitted environmental conditions, are prerequisites for ensuring safe and trouble free operation.

Detailed explanation of hardware installation

Hardware installation is the first step to ensure the stable operation of the communication processor and must strictly follow the regulations:

Safety preparation: It is necessary to operate with a complete power outage. Turn off the PC/PG and unplug the power cord to prevent the risk of electric shock.

Electrostatic protection: Communication processors belong to electrostatic sensitive devices (ESD). When operating, touch the grounded metal surface to release body static electricity. When holding the module, only touch the edges to avoid touching the pins or circuits. Tools should also undergo anti-static treatment.

Installation steps:

Open the computer case, find an empty PCI slot, and remove its cover.

Remove the communication processor from the anti-static packaging, insert it vertically and firmly into the PCI slot, ensure complete contact with the gold fingers, and secure it with screws to prevent poor contact due to vibration.

Some chassis designs may allow for module tilt installation, which is allowed.

Close the chassis and reconnect the power supply.

Compatibility and Replacement:

Each PG/PC supports the installation of up to 4 communication processors, of which up to 2 can be in 'configured' mode.

CP 5613 A2/CP 5614 A2 can directly replace the old models CP 5613/CP 5614. When replacing, the old module needs to be physically removed first. If the new module uses the configuration of the old module, the configuration data needs to be downloaded again. Special note: The DP slave configuration of CP 5613 A2 cannot be directly downloaded to CP 5614 A2, otherwise the slave function will not work properly.

Software installation and driver management

Software is the soul that drives hardware. The drivers for two communication processors are integrated into the SIMATIC NET PC software package.

Software installation sequence: It is strongly recommended to follow the principle of "software first, hardware later". Before inserting the communication processor card, "SIMATIC NET PC Software" (version 11/2003 or higher) or the corresponding development toolkit should be installed on the operating system.

Driver installation: After the hardware is installed and powered on, Windows' plug and play feature will automatically detect new hardware. The user should follow the hardware wizard, manually specify the driver location (point to the installed SIMATIC NET software directory), and uncheck the "Search for drivers on the Internet" option to ensure that the correct local driver is installed.

Alternative software: In addition to the complete SIMATIC NET PC software, users can also use software packages such as STEP 7 (V5.5 or higher) or STEP 7 Professional (TIA Portal V11 or higher) to operate the communication processor.

Uninstalling: Uninstalling the driver is equivalent to uninstalling the entire SIMATIC NET PC software package. You need to use the program uninstallation function in the control panel or use the software's built-in uninstallation program to follow the instructions in the installation manual.

Configuration Guide

The communication processor must be correctly configured in the configuration software before it can be put into network communication. The main configuration tools are STEP 7 or SIMATIC NCM PC. The detailed configuration process (such as setting station addresses, selecting protocols, allocating I/O data, etc.) should refer to the independent "Commissioning PC Stations" configuration manual (entry ID: 13542666). The core of configuration is to define CP as DP master or slave based on network planning, and establish logical connections with other devices on the network.

LED status indication and diagnosis

The dual color LED on the panel is an important diagnostic tool, with the following meanings:

Green constantly on (DP master station): The token cycle is normal and the bus is running normally.

Green off (DP master station): Bus parameter error, bus fault, or CP not running.

Green 1-second interval flashing (DP master station): Database error.

Green and yellow flashing alternately: currently being accessed by diagnostic tools to check installation.

Yellow constantly on (DP slave): Polling by upper level DP master, running normally.

Yellow off (DP slave): not addressed by the master station.

Red flashing rapidly: module not started (normal state after reset).

Green and yellow synchronous flashing: firmware error (abnormal state).

By observing the LED status, the working status of the communication processor can be quickly determined and faults can be preliminarily located.

Detailed technical specifications

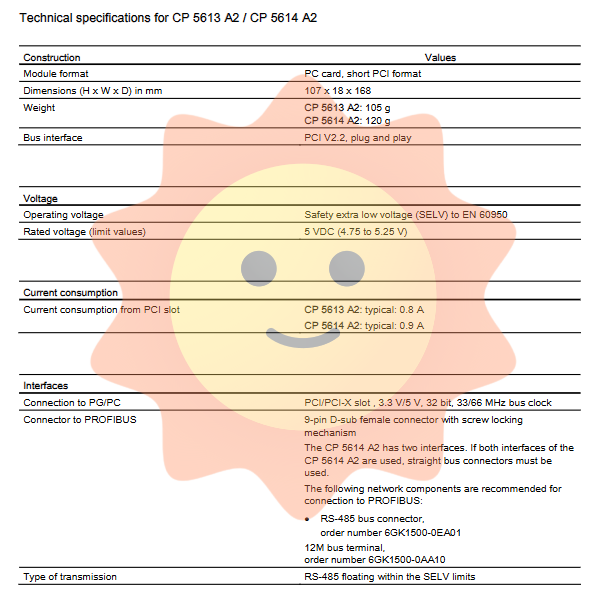

The two processors have a compact design (107x18x168 mm) and weigh approximately 105g (CP 5613 A2) and 120g (CP 5614 A2). The core specifications are as follows:

Electrical characteristics: Operates at 5V DC safe extra low voltage (SELV), with a typical power consumption of 0.8A for CP 5613 A2 and 0.9A for CP 5614 A2.

Interface: PCI V2.2 interface, supports 3.3V/5V, 32/64 bits, 33/66 MHz. The PROFIBUS interface is a 9-pin D-Sub and adopts a floating RS-485 design (signal isolation). It is recommended to use specialized bus connectors such as Siemens 6GK1 500-0EA01.

Environmental adaptability:

Working temperature: Complies with DIN EN 60068-2 series standards.

Storage/transportation temperature: -40 ° C to+70 ° C.

Humidity: up to 85% @ 30 ° C during operation (no condensation).

Vibration and impact resistance: meets the industrial environment requirements of DIN EN 60068-2-6 (vibration) and -2-27 (impact).

Electromagnetic compatibility:

Emission: Compliant with EN 55022/FCC Class B.

Immunity: Signal line surge immunity ± 2kV, electrostatic discharge immunity ± 6kV, RF field immunity 10V/m (80MHz-2GHz).

Certification and Compliance

CP 5613 A2 and CP 5614 A2 have obtained authoritative certifications in multiple regions around the world, ensuring their compliance with strict safety and electromagnetic compatibility standards:

EU CE Mark: Compliant with EMC Directive 2004/108/EC, suitable for industrial environments (EN 61000-6-4/-6-2) and residential/commercial environments (EN 61000-6-3/-6-1). Its conformity statement can be found on the product support website (entry ID: 63367995). This product itself does not fall within the scope of mechanical instructions.

North American certification:

CULus: Certified according to UL 60950-1/CAN/CSA C22.2 No. 60950-1 standards.

FCC: Complies with the Class B digital device restrictions under Part 15 of FCC regulations. Require the use of shielded I/O cables to connect peripheral devices.

ICES: Complies with the Canadian ICES-003 B-level digital device standard.

Australian C-Tick: Compliant with AS/NZS 3548 standard.

It should be noted that all authentication is only valid when the corresponding mark is printed on the communication processor.

Support and Resources

Siemens provides a strong after-sales support system:

Product Support Website: Provides the latest operating instructions, manual updates, product information, FAQs, and software patches.

Technical Forum and Support: Users can ask Siemens experts for technical consultation and engineering support.

SITRAIN Training: Provides over 300 courses on automation and drive technology, covering comprehensive product training from basic to advanced levels.

SIMATIC NET Manual Collection and Terminology Library: All relevant documents can be obtained online through entrance ID 10805878, and terminology explanations can be found in the SIMATIC NET Terminology Library (entrance ID: 50305045).

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor

- SHINKAWA