Comprehensive Analysis and Configuration Guide for Siemens ET200SP Distributed I/O System

Comprehensive Analysis and Configuration Guide for Siemens ET200SP Distributed I/O System

Introduction

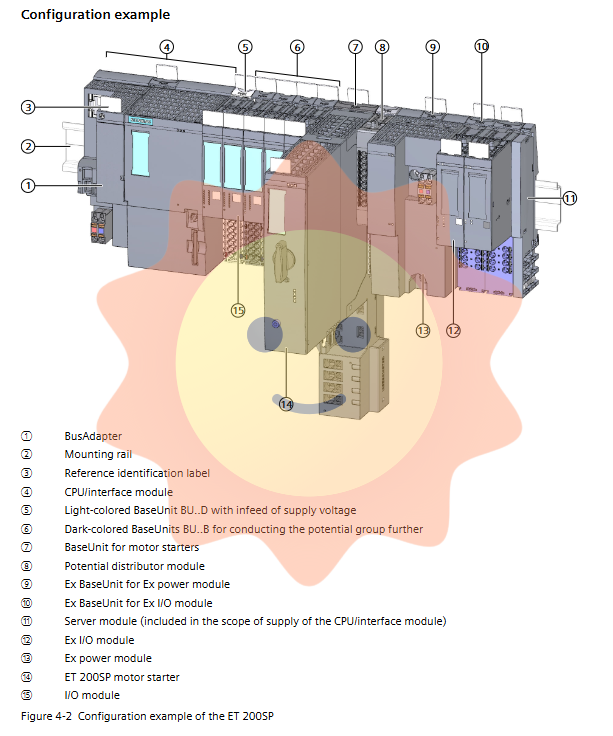

In industrial automation systems, reliable, flexible, and efficient signal acquisition and control are the foundation for achieving intelligent manufacturing. The Siemens SIMATIC ET 200SP distributed I/O system, as a modular I/O solution widely used in the automation field, has become an important component of modern industrial control systems due to its high scalability, flexible configuration options, and powerful integration capabilities. This article is based on the official system manual and provides a comprehensive analysis of the technical characteristics, hardware structure, application planning, installation configuration, and security functions of the ET200SP system. The aim is to provide automation engineers and system integrators with a systematic, professional, and practical technical guide.

Overview and Core Advantages of ET200SP System

1.1 What is the ET200SP distributed I/O system?

SIMATIC ET 200SP is a highly modular and scalable distributed I/O system used to connect process signals to upper level controllers via fieldbuses such as PROFINET IO, PROFIBUS DP, EtherNet/IP, or Modbus TCP. The system adopts a compact design with a protection level of IP20, suitable for installation inside control cabinets. ET200SP not only supports standard signal modules, but also integrates fault safety modules, motor starters, communication modules, and specialized technical modules, meeting the comprehensive needs of applications from simple to complex, from standard to safety critical.

The maximum configurable system includes: one CPU/interface module, up to 64 I/O modules (any combination), up to 31 motor starters, and one service module for completing system configuration. Its module width is only 15 mm or 20 mm (some modules), greatly saving control cabinet space.

1.2 Core advantages and typical applications

Highly flexible and scalable: Users can flexibly combine various modules such as digital, analog, fault safety, communication, technology, and motor starters according to on-site needs. The system supports the "hot plug" function, which allows for module replacement during operation, greatly improving the system's availability and maintenance convenience.

Integrated safety functions: Through the fail safe CPU (F-CPU) and fail safe I/O module (F-I/O), ET200SP can build a safety automation system that complies with IEC 61508 (SIL 3) and ISO 13849-1 (PL e/Cat. 4), replacing traditional safety relay solutions such as emergency stop, safety door monitoring, and manual operation.

Enhance system availability: Support PROFINET system redundancy R1. The ET200SP R1 system is equipped with two redundant interface modules. In the event of a main interface failure, the backup interface can seamlessly take over, ensuring continuous communication and high availability of the site.

Simple engineering and maintenance: Unified configuration and programming through Siemens TIA Portal (fully integrated automation portal). The system supports rich diagnostic functions, identification, and maintenance data (I&M) for quick troubleshooting. In addition, the front of the module provides a QR code (ID link), which can be scanned to directly access the digital nameplate of the product and obtain the latest information such as manuals and certificates.

Detailed explanation of system hardware composition

The ET200SP system consists of a series of standardized components, and understanding its functionality is the foundation for proper application planning.

2.1 Core Components

CPU/fail safe CPU: As the intelligent core of the system, it is responsible for executing user programs (the safe CPU also executes safe programs) and can run as an IO controller, I-device, or independent CPU. It exchanges data with I/O modules through the backplane bus and integrates various functions such as web server, tracking function, system diagnosis, and security mode.

Interface module: used to connect ET200SP as an IO device to the upper control system. According to different communication protocols, it is mainly divided into:

PROFINET IO interface module

PROFIBUS DP interface module

Multiple fieldbus interface modules (supporting PROFINET IO, EtherNet/IP, Modbus TCP)

PROFINET Redundant Interface Module (IM 155-6 PN R1)

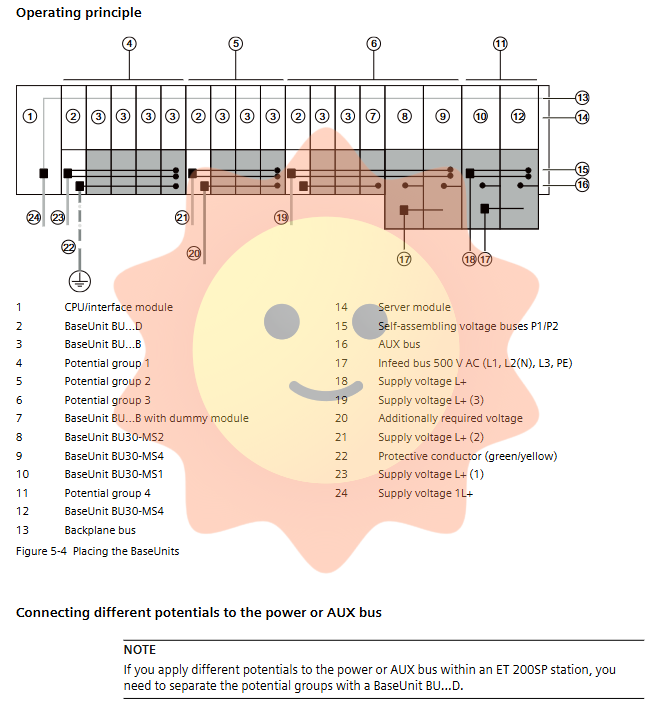

Basic unit: It is the mechanical and electrical installation base for I/O modules or motor starters, and provides wiring terminals. The basic unit is divided into two types: light color (BU.. D) and dark color (BU.. B), which are respectively used for "opening a new potential group" and "continuing the existing potential group". The correct selection of basic units is the key to forming potential groups and distributing power sources.

I/O module: determines the function of the terminal, including digital input/output, analog input/output, technical module, communication module, power module, etc., and has multiple types such as standard type, fail safe type, intrinsic safety type (Ex), etc.

Motor starter: a direct or reversible starting device that integrates switch and protection functions, used to control single-phase or three-phase loads, and also provides standard and fail safe types.

Potential Distributor Module: Composed of PotDis Base Unit and PotDis Terminal Block, it is used to efficiently distribute sensor power (such as P1/P2) within the system, replacing external terminal blocks, saving space, and simplifying multi wire connections (such as 3-wire connections for 16 channel digital modules).

Service module: Installed at the far right end of the configuration, it is used to complete the electrical connection of the ET200SP system and contains a spare fuse holder inside.

Bus adapter: Provides physical connection options for PROFINET IO interfaces, supporting various media and connector forms such as RJ45, M12, optical fiber (POF/PCF, glass fiber), etc.

2.2 Attachments and Coding

Attachment: Includes 24V DC power plug, shielding connection kit, label strip, reference identification label, color identification label, etc., used to improve the power supply, shielding, identification, and maintenance of the system.

Encoding components: divided into two types: mechanical encoding and electronic encoding. Mechanical coding ensures that I/O modules are paired with the correct type of base unit; The electronic coding component also includes a rewritable memory for storing module specific configuration data (such as the F target address of the fail safe module).

Key points of application planning and configuration

3.1 Basic Unit Selection Rules

The choice of basic unit depends on the installed I/O module or motor starter. The last two letters of the order number for each I/O module indicate the compatible base unit type (such as "A0", "B1"), and the module body is also printed with words such as "BU: A0". The manual provides detailed comparison tables, such as:

BU type A0/A1: Analog module (15 mm wide) for digital, fault safety, communication, technical, or temperature measurement without 24V DC.

BU type B0/B1: Used for digital modules up to 230V AC (20mm wide, dark color).

BU type C0/C1/U0, etc.: Used for specific modules such as fail safe power modules, AS-i master stations, energy measurement meters, etc.

BU30 MSx series: specifically designed for motor starters, divided into models based on whether they include 24V DC feed, 500V AC feed, F-DI feed/routing, and other functions.

Key note: The first 24V DC I/O module must be installed on the light colored base unit (BU.. D). If the first module is an AC I/O module or AI energy meter and uses a CPU/interface module with firmware version V3.0 or higher, the first base unit can also be a dark type B1 or D0.

3.2 Formation of potential group

Potential group is a logical group that systematically distributes power (L+/M and AUX bus) through the arrangement of basic units.

Light colored basic unit: Start a new potential group (power supply and AUX bus interrupt to the left) and feed in the power supply.

Dark base unit: Continuing the current potential group and capable of tapping power from it.

Rule: Each potential group starts with a light colored base unit, followed by several dark colored base units. Different potential groups (such as 24V DC and 230V AC) must be isolated using light colored base units. AUX bus can be used to conduct protective grounding (PE) or other potentials. When used as a PE strip, yellow green identification labels should be used and both ends should be mechanically fixed.

Motor starter potential group: The motor starter has an independent 500V AC feed bus (for main power supply) and 24V DC power bus (for control electronics). The basic unit model determines whether to feed or continue the routing of these buses and F-DI signals.

3.3 Hardware Configuration Limitations

Mechanical configuration: The maximum number of modules that can be installed depends on the CPU/interface module used (usually 12 to 64), with a maximum of 31 for motor starters. The total length (installation width) of the backplane bus shall not exceed 1 meter.

Electrical configuration: The maximum load current of a potential group is limited by the current carrying capacity of the base unit terminals (usually 10A) and the power supply capacity of the power source. The maximum current carrying capacity of the 24V DC bus of the motor starter is 7A, and the maximum current carrying capacity of the 500V AC feeder bus at 50 ° C is 32A (note the derating curve).

Address space: depends on the addressing capability of the CPU/interface module and upper layer controller used.

Installation, wiring, and safety regulations

4.1 Installation foundation

Environment: ET200SP is an open device that must be installed in a control cabinet, enclosure, or electrical operating room with the corresponding protection level (IP20) to ensure protection against electric shock and fire spread.

Installation rail: Standard installation uses 35 mm x 7.5 mm or 15 mm DIN rails that comply with ISO 60715. The ET200SP R1 system must use dedicated SIMATIC system rails. In environments with high vibration and impact, it is recommended to use system rails and mechanically fix the two ends of the ET200SP component.

Installation sequence: From left to right, it is CPU/interface module → basic unit (starting with light colors for new potential groups) → I/O module/motor starter → service module. Installation must be carried out in a power-off state.

4.2 Key Wiring Rules

Cable cross-section: For push in terminals of CPU/interface modules and I/O base units, it is allowed to use solid wire or twisted wire (with wire nose) of 0.2-2.5 mm ² (AWG 24-13).

Shielded connection: It is recommended to use shielded cables for analog modules, etc. The shielding connection kit can connect the low impedance ground of the cable shielding layer to the installation rail (functional grounding). Note that the shielded terminal does not have a zero potential terminal, and can only be tightened after inserting at least one cable.

Safe Voltage: The fault safety module and motor starter must be powered by a Safety Extra Low Voltage (SELV/PELV) power supply with a rated voltage of 24V DC and a tolerance range of 19.2-28.8V DC and 20.4-28.8V DC, respectively. It is necessary to use a power supply with an output voltage not exceeding 36V DC even in the event of a fault, or take overvoltage protection measures.

Sensors and actuators: To achieve the required safety level (such as SIL3/Cat.4), suitable safety sensors and actuators need to be selected. For fault safety input, the sensor signal "0" should correspond to the safety state (such as emergency stop press). The actuator must be able to withstand brief on-off cycles of periodic test pulses from the output module.

4.3 Safety and EMC precautions

Equipotential connection: To ensure stable operation of the system and discharge interference, a good grounding system should be established. The guide rails installed inside the cabinet should be grounded separately.

Cable separation: To avoid crosstalk (capacitive or inductive) between digital input/output signals, especially for fail safe signals, it is recommended to use separate cables or cable conduits for F-DI, F-DQ, and F-PM-E modules.

Short circuit protection: The motor starter complies with Type 1 coordination. Users need to configure appropriate short-circuit and overload protection devices for incoming cables and motor feeder cables according to national regulations.

System configuration, programming, and diagnostics

5.1 Configuration Tools

Mainly using Siemens STEP 7 (TIA Portal) for hardware configuration and parameter allocation. It also supports configuration in third-party engineering software through GSD/GSDML files. In addition, Siemens also provides a range of auxiliary tools:

TIA Selection Tool: Used for product selection and generating order lists.

SIMATIC Automation Tool: Used for batch execution of CPU commissioning and maintenance tasks (such as assigning IP addresses, downloading programs, firmware updates).

PRONETA: Used for fast debugging and diagnosis of PROFINET networks.

SINTEPLAN: Used for planning and optimizing PROFINET networks.

MultiFieldbus Configuration Tool: Used to configure devices that support multiple fieldbuses.

5.2 Configuration Control (Option Handling)

This is a powerful feature that allows multiple actual device variants (station options) to be run with a "maximum configuration" project (station master) without modifying the project or program.

Principle: In the user program, a control data record (Data Record 196) is used to inform the CPU/interface module which modules are missing in the station options and which modules are located in different slots. The CPU/interface module adjusts its internal mapping accordingly.

Step: 1) Enable the "Allow reconfiguration through user program" parameter of the device in STEP 7. 2) Create a data block that contains a control data record structure. 3) In the startup of OB, use the WRREC instruction to send control data records to the CPU/interface module.

Advantages: Simplify project management, achieve flexible utilization of hardware resources, facilitate version management and later expansion of standard machines.

5.3 Diagnostic and protective functions

Value Status: Some I/O modules support providing "quality bits" (value status) for each channel, which can be accessed through process mapping input. The value status' 0 'indicates that the channel value is invalid (such as disconnection, short circuit, power loss, channel disabled, etc.).

Access protection: The CPU provides four access levels (full access, read access, HMI access, no access), which can restrict online access to hardware configuration and programs through password restrictions.

Proprietary technology protection and copy protection: Passwords can be set for individual program blocks to prevent code from being viewed or modified. Blocks can also be bound to specific CPU or storage card serial numbers for copy protection.

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor

- SHINKAWA