Siemens SINUMERIK 840C CNC System Installation and Debugging Guide

Siemens SINUMERIK 840C CNC System Installation and Debugging Guide

Siemens SINUMERIK 840C is a high-performance CNC system widely used in the field of machine tool control. Combined with the SIMODRIVE 611-D digital drive system, high-precision and high dynamic response motion control can be achieved. This article is based on the official SINUMERIK 840C SIMODRIVE 611-D Installation Guide (version 09.2001), which systematically outlines the entire process of installation, configuration, and debugging, covering various aspects from hardware preparation to software optimization, from PLC integration to driver debugging, providing a complete and professional technical reference for machine tool manufacturers and debugging engineers.

System Overview and Preparation Before Installation

The SINUMERIK 840C system adopts a modular design, including core units such as NCK (numerical control core), MMC (human-machine communication), and PLC (programmable logic controller). The system supports both analog and digital drivers, with SIMODRIVE 611-D being a fully digital driver system with stronger communication capabilities and debugging flexibility.

The following prerequisites must be met before installation:

The mechanical and electrical installation of the machine tool has been completed, and all axes are ready for operation.

The customer's PLC program has been written and preliminarily tested.

The measurement system (such as grating ruler, encoder) has been installed and wired to the SINUMERIK interface.

All cables have been connected, and the shielding layer is grounded according to the interface instructions.

The grounding system complies with DIN VDE 0160 standard and adopts star shaped grounding points for centralized grounding.

The customer needs to provide personnel support for interface debugging, machine operation, and PLC program verification.

Visual Inspection is a critical step that requires focused inspection of:

Module handling: Electrostatic sensitive devices (MOS modules) require special protection to avoid direct contact with printed circuits.

Grounding system: Ensure that the grounding wire has no loops, the cross-section meets the requirements, and achieve equipotential connection.

Position encoder: installed in accordance with specifications (such as air gap, coupling), correctly wired and well shielded.

Cable laying: Power cables and control cables are routed separately to avoid grounding loops, and the minimum bending radius meets the requirements.

Shielding and anti-interference: All cable shielding layers entering and exiting the control cabinet must be grounded through connectors, and relays and motors must be equipped with suppressors.

Operation panel: The buttons, indicator lights, and display functions are normal.

Overall status: The module is securely installed, the front cover screws are tightened (grounded), and the accessory package is complete (including logs, spare parts list, transparent cover plate, etc.).

Hardware installation and electrical inspection

1. Voltage and functional testing

After the system is powered on, NCK and MMC will perform a self-test program. If a system program verification error is detected in the NCK area, the red LED will continue to flash and enter a stop state. The MMC area will display startup information, including memory testing, interrupt controller detection, etc. Starting from software version 4, the system will automatically perform a hard disk consistency check upon startup, and it is recommended to perform it regularly to free up disk space.

2. Data loading process (software version 2 and above)

When the system starts up, data is loaded from the MMC hard drive into NCK in three stages:

Stage 1: Load NCK system programs (such as during DRAM data loss or forced startup).

Stage 2: Load user data, including user customized UMS (if any) and NC data files under the user branch.

Stage 3: Load standard workpiece data.

3. Standard/export version identification

Due to export controls, 840C offers standard version (840C) and export version (840CE). The export version prohibits 5D interpolation, interpolation and table compensation (IKA) and other functions. The system software version determines the control properties, and replacing or upgrading the software may require an export license for the control system. The control version can be identified through delivery notes, invoices, and software packaging labels. After startup, the export version will display an additional character "E" in the service screen.

Software Configuration and Standard Startup

1. Universal reset and standard startup (software version 3 and above)

For newly installed or data lost systems, it is necessary to enter the "universal reset mode" for standardized startup. In this mode, the following key operations can be performed:

Format NCK user memory: Clear user data (machine data, R parameters, tool data, etc.) from SRAM to ensure consistent initial state.

Delete digital drive configuration file: Only applicable to digital drive systems.

Save PLC user program to hard drive: Save the current PLC program as an ANW-PROG file for easy loading in the future.

End universal reset mode: Trigger power on reset to make the settings effective.

Important note: Starting from software version 6, NCK's SRAM will automatically clear upon software updates or CSB battery failures to ensure the defined initial state.

2. Memory configuration (software version 3 and above)

Users can flexibly configure the allocation of DRAM and SRAM according to their needs:

DRAM: Used for storing part programs, UMS, IKA data, block buffers, measurement value storage, etc. The capacity depends on the software version (such as SW 4.1-4.3 supporting a maximum of 2760 kB of part program storage).

SRAM: Used for tool compensation, R parameters, and other data that need to be powered off to maintain. The total capacity is 64 kB, which can be allocated between tool compensation and R parameters.

After changing the memory configuration, the 'NCK Format User Memory' operation must be performed in universal reset mode.

3. Machine tool data loading

Standard data or user files can be loaded through the "Machine Data Dialogue". At initial startup, the system loads standard data files under the SIEMENS branch (such as STAND_T, STAND_M). Subsequent launches can load customized files under the user branch. If the file contains driver data, it is necessary to confirm the driver related alarms during the loading process and reload the driver configuration after completing the universal reset.

PLC installation and diagnosis

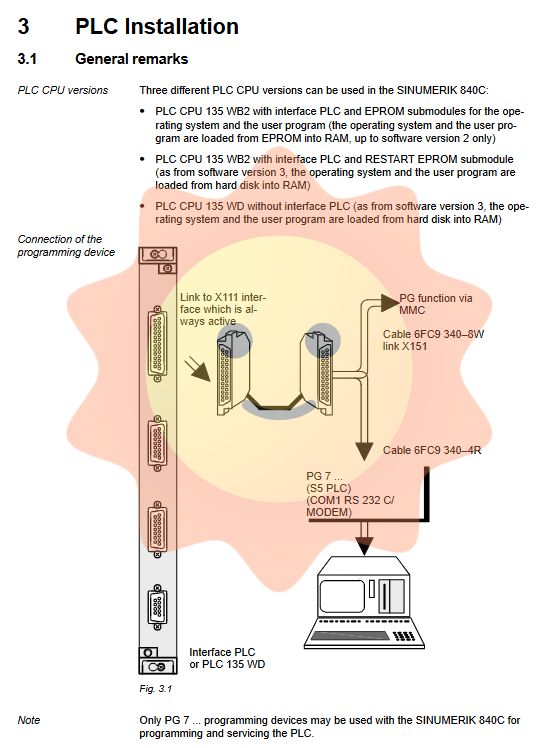

1. PLC CPU version and connection

840C supports three types of PLC CPUs:

PLC 135 WB2 (with EPROM submodule, suitable for software version 2 and below).

PLC 135 WB2 (with REST EPROM submodule, software version 3 and above).

PLC 135 WD (no interface PLC, software version 3 or above).

Programming devices are limited to the PG 7xx series and are connected via NC-PG cables. The interface parameters are fixed at 9600 baud, even parity, and 2 stop bits.

2. PLC universal reset and start

Before starting the PLC, the user program needs to be loaded into the RAM of the PLC CPU. For software versions 3 and above, programs are usually loaded from the hard drive. In the universal reset mode, the "PLC initial clear" can be executed to delete the user program in RAM, and then the ANW-PROG file can be loaded from the hard disk. If the file does not exist, the RAM remains empty.

3. PLC diagnostic function

The system provides multiple diagnostic tools:

LED display: Indicates hardware malfunction.

System initialization program: Check the startup conditions and decide whether to perform a cold start or a hot start.

Detailed Error Code (USTACK): Provides precise error information when the PLC stops, which can be accessed through Diagnosis>Service Display>PLC Service.

PLC status: can view and modify the values of input/output words, flag words, data words, timers, and counters (password required).

Timeout analysis: By setting the MD bit 6049.0 of the PLC operating system, buffer access to the communication/local bus can be disabled to accurately locate the cause of timeout.

MMC regional diagnosis and configuration

1. Password protection

Both NCK and MMC regions are password protected. The password is set through NC MD 11, with a default value of 0 corresponding to password 1111. Passwords can be set or deleted in the diagnostic area. Password error will prompt 'PASSWORD INCORRECT'.

2. Language switching (software version 5 and above)

At the initial screen of the diagnostic area, the language of subsequent input screens can be switched through the soft key "Language/Sparche". The switchable areas include system (MMC, NCK), WOP, simulation, and PG software. Only installed languages will appear in the switching options.

3. Screen hard copy printing

Hard copies are stored in compressed TIFF or PCX format and can be transmitted via RS232 interface. The format is set in the BEDCONF configuration file (such as a 15 1 CO for color and a 15 6 TIFF for TIFF format).

4. PC data management and configuration editing

Users can access MMC's file system through Diagnosis>Startup>PC Data. The system data is stored in two branches, SIEMENS and USER. The USER branch is editable, while the SIEMENS branch is the default setting for protected systems. The 'PRESSET' soft key can be used to copy files from the SIEMENS branch to the USER branch.

The key configuration files include:

CONFIG file: defines language, operation panel interface, alarm log format, message priority, etc.

BEDCONF file: Parameterize the overall behavior of the operating system, such as application management, color mode (CO/MO), display mode (PO/NE), screen saver time, etc. Editors need to be extra cautious, as errors can lead to system failures.

Color Chart (CLUT) and Color Mapping List: Allow users to customize the color scheme for each display area.

5. Data Backup (Backeup)

By using VALITEK streaming tape drive or PC link, all data on the hard drive (system software, user software, part programs, machine data) can be fully backed up. This is a necessary measure to prevent data loss caused by MMC CPU failure. The backup function is located in the Diagnosis>Startup>ACKUP menu, where you can select operations such as backing up the system, backing up user data, and restoring the system.

Machine tool data dialogue (MDD - software version 3 and above)

MDD provides a graphical data input interface, replacing the traditional list input method.

1. NC configuration and machine tool data

In the NC configuration screen, the attribution relationship between channels, axes, spindles, and mode groups can be set, and axis names, axis types (straight/rotary), virtual and real axes, etc. can be defined. Subsequent NC machine tool data will be displayed grouped by function, including:

General NC MD

Geometry and Motion

Channel related data

Axis related data (basic data, monitoring and limiting, speed, measurement system, controller data, etc.)

Spindle related data

Gearbox interpolation data

Memory configuration data (software version 4 and above)

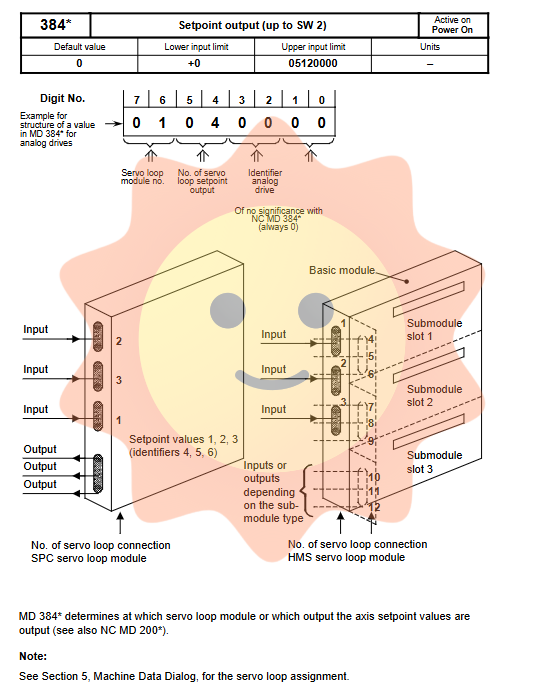

The allocation of set values/actual values is a key step before driving debugging, and the corresponding driving/measuring circuit module number needs to be correctly set in the basic MD of the shaft or spindle.

The adaptive function of the measurement system (software version 4 and above) can automatically calculate the position control resolution and measurement system resolution, optimizing closed-loop control. After the user inputs parameters such as screw pitch, grating pitch, encoder pulse per revolution, pulse doubling, etc., the system automatically calculates and fills in the corresponding MD.

2. PLC configuration and machine tool data

The PLC configuration screen is used to configure the availability, address, lathe type (T/TT), and directional key processing method (processed by the PLC operating system or user program) of two machine tool control panels. PLC machine tool data is divided into peripheral device settings, alarm messages, PLC basic data, user MD, tool management, computer links, and other areas.

3. Driver configuration and machine tool data

The driver configuration screen is used to activate and configure the actual FDD (feed drive) and MSD (spindle drive) modules. The user needs to select the module model and change its status from "passive" to "active". After completion, the 'Accept Configuration+NCK Power On' soft key must be used to update the boot files on the hard drive and initialize the driver bus.

Detailed grouping of driving machine tool data, including:

Motor/power unit data

Monitoring and Restrictions

message data

Measurement system data

Controller data (speed loop, current loop, etc.)

Status data

Digital driven startup: can be done by loading an existing TEA3 file or through the standard startup process (selecting module and motor model). The system will preset driving parameters using standard data from the controller. For non Siemens motors, manual input of motor data is required, followed by the use of the 'Calculate Controller Data' function.

4. File function

MDD supports managing data files at three levels:

Level 1: Machine Configuration: Manage data files for all areas (TEA1, TEA2, TEA3, etc.), and can save or load the entire machine configuration at once.

Level 2: Each data area: manages drivers NC、PLC、 Loop and IKA data files.

Level 3: Sub regions within each data area: finer file management.

The user display function allows users to customize the list of machine tool data they are most concerned about, and configure it through the "Edit List" soft key to improve debugging efficiency.

Installation and commissioning of shafts and spindles

This is a crucial stage in integrating the control system with the physical axis of the machine tool.

1. Shaft installation

Drive optimization: Check and set the control direction of the feed axis; Perform speed setting value matching/speed measurement machine compensation; Set servo gain factor Kv; optimize acceleration and acceleration limits; Configure location monitoring and dynamic contour monitoring.

Drift compensation: compensates for position deviation when stationary.

Axis motion test: Test axis motion in jog mode and program control mode.

Reference point proximity: Configure different zeroing methods (with/without automatic direction recognition, program control, no motion zeroing, etc.). For the reference markers of distance encoding, initial installation settings are required.

2. Spindle installation

Control modes: including open-loop control mode, oscillation mode, and positioning mode (M19).

Detailed explanation of positioning mode: involving absolute and incremental positioning sequences, gain factor changes, positioning termination, etc.

Acceleration feature (software version 4 and above): configurable curve acceleration feature.

PLC intervention: PLC can intervene in the spindle control process.

Data backup and CPU replacement

1. Data backup method

Streaming tape drive: Fully backup MMC hard disk data.

V24 interface or floppy drive: transfers specific data files.

Hard disk boot: The control system can be started using user data.

2. CPU replacement process

After replacing the MMC CPU or NCK CPU, data needs to be restored from the backup. For MMC CPUs, "system recovery" is typically performed using a streaming tape drive. For NCK, system programs and user data need to be loaded through the V24 interface or network.

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor

- SHINKAWA