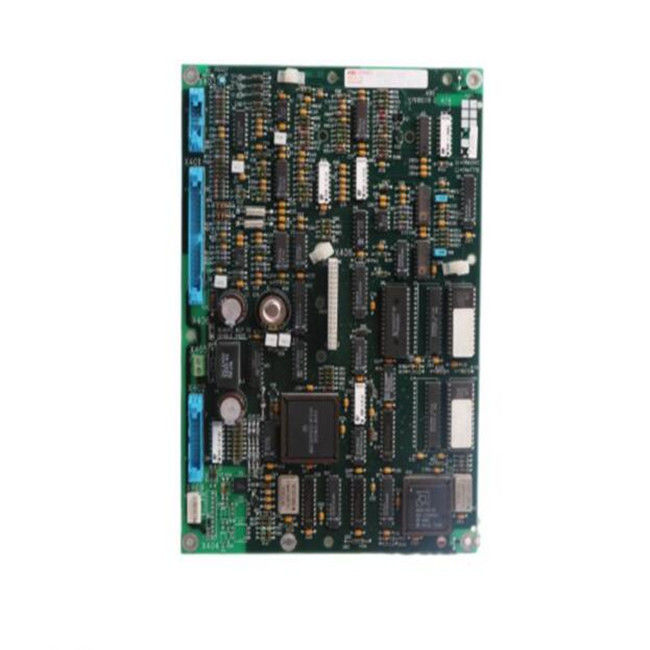

ABB SNAT603 CNT Control Board

Connected to actuators: Connected to motors, solenoid valves, cylinders, and other actuators through output interfaces to control the action and operation of the equipment.

Connect with the upper computer: Connect with the upper computer (such as PLC, industrial control computer, etc.) through Ethernet or other communication interfaces, receive instructions and programs from the upper computer, and send equipment operation data and status information to the upper computer.

Working principle

Receiving instructions: Receive control instructions and programs from upper level computers (such as PLCs, industrial control computers, etc.) through communication interfaces, which contain information such as equipment operating parameters, action sequences, task requirements, etc.

Data processing: parsing and processing received instructions, while collecting data from connected sensors such as position sensors, speed sensors, pressure sensors, etc., analyzing and computing these data according to preset algorithms and logic to determine the current state of the device and the next control strategy.

Output control signal: Based on the results of data processing, generate corresponding control signals and send them to connected actuators such as motor drivers, solenoid valves, relays, etc. through output interfaces to control the actions of the actuators and achieve precise control of the equipment.

Feedback and adjustment: Real time monitoring of the operating status and feedback signals of the equipment, comparing the actual operating situation with the preset goals, and adjusting the control strategy and output signals in a timely manner if there is a deviation, to ensure that the equipment operates according to the predetermined trajectory and parameters, achieve closed-loop control, and improve control accuracy and stability.

Precautions

Installation environment: It should be installed in a dry, well ventilated environment without severe vibration and electromagnetic interference. Avoid installing in damp, dusty, high-temperature, or corrosive gas environments to prevent affecting the performance and service life of the control board. The installation location should be away from strong electromagnetic interference sources such as large motors and transformers. If unavoidable, effective shielding and grounding measures should be taken.

Power connection: When connecting the power supply, it is necessary to strictly follow the product specifications and correctly connect the appropriate power supply voltage and phase sequence. Check whether the power supply circuit is firm and reliable to prevent loosening, short circuits, and other situations. It is strictly prohibited to connect or disconnect the power supply while it is live, in order to avoid electric shock accidents or damage to the control board.

Operation and maintenance: Operators should receive professional training and be familiar with the operation methods and parameter settings of the control board. When adjusting parameters, caution should be exercised to avoid abnormal device operation caused by incorrect settings. Regularly clean and inspect the control board, remove dust and debris from the surface, check for loose interface connections, and inspect for signs of damage to components. If any abnormalities are found, the equipment should be shut down in a timely manner for handling, and it is strictly prohibited to operate the equipment with problems.

Software upgrade: If a software upgrade is required, the original configuration data should be backed up first to avoid data loss during the upgrade process. Download officially recognized upgrade software and follow the correct upgrade steps. During the upgrade process, ensure stable power supply to the equipment to avoid upgrade failure caused by power outages or other reasons, which may result in damage to the control board.

Similar model supplement

The SNAT603CNT series also includes other models, such as:

SNAT603CNT-40207041: Its rated current is 4A. Compared with SNAT603CNT-6100041, it has better applicability in some industrial equipment control scenarios with relatively small current requirements, which can effectively reduce costs while ensuring stable operation of the equipment. Suitable for small motor drive control, partial sensor power supply and control scenarios.

SNAT603CNT-80407041: With a rated current of 8A, it can provide stronger power support for equipment with high electricity demand. In the control system of large mechanical equipment, such as joint drive of large industrial robots and speed control of high-power motors, the advantages of high current output can be fully utilized to ensure stable operation of the equipment under high load and high requirements.

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor

- SHINKAWA

- Other Brands