TRICONEX Trident Controller

Deep Technical Analysis of Trident Safety Instrumented System

Trident control system, as an outstanding representative in the field of industrial automation, is specifically designed for low point applications and distributed I/O scenarios. Its core architecture is based on advanced Triple Modular Redundancy (TMR) technology, providing unparalleled safety and availability for critical industrial processes through highly reliable hardware design and intelligent diagnostic mechanisms. This article will delve into the various technical specifications of the Trident system, from the core processor to various I/O modules, to environmental adaptability and international certification, providing you with a detailed technical reference guide.

Core Architecture: Main Processor and Communication Module

The "brain" of the Trident system consists of a main processor module and a communication module, which work together to ensure real-time data processing and smooth external communication.

1. Main processor module

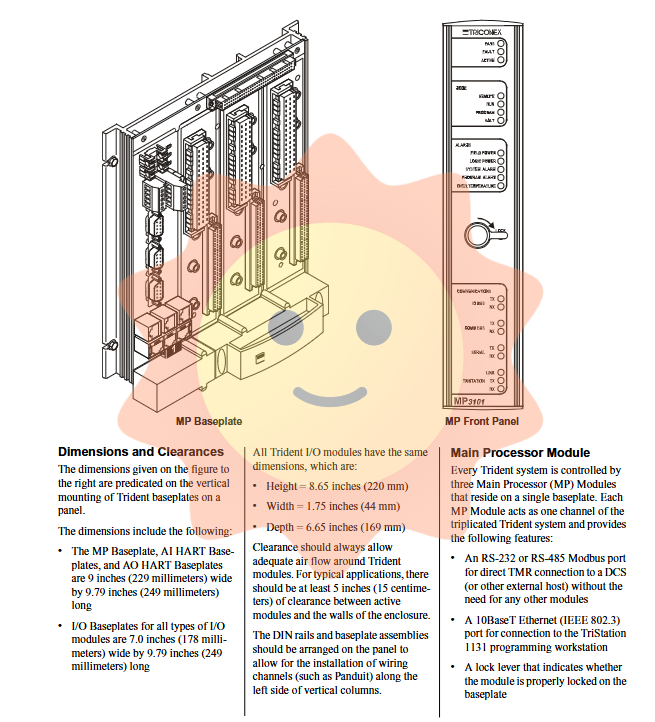

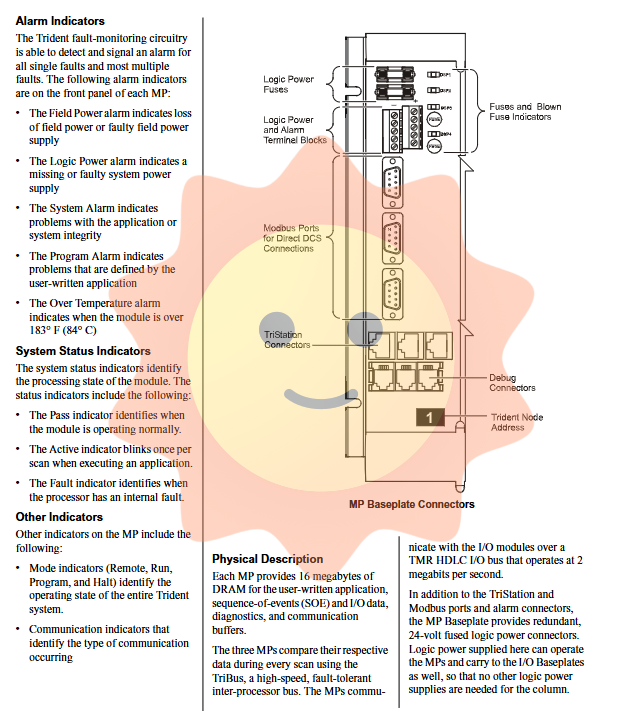

Each Trident system is jointly controlled by three main processor modules, which are installed on the same motherboard and run as independent channels of the triple redundant system. This design ensures that the system can maintain normal control logic even in the event of a single channel failure. The MP module provides powerful processing capabilities, equipped with 16MB of DRAM memory for storing user written applications, sequence of events (SOE) data, I/O data, and communication and diagnostic buffers.

In terms of communication interfaces, the MP module has extremely high flexibility. It provides an RS-232 or RS-485 Modbus port, allowing for direct TMR connection with DCS or other external hosts without the need for additional intermediate modules. In addition, it also has a built-in 10BaseT Ethernet (IEEE 802.3) port specifically designed for connecting to the TriStation 1131 programming workstation.

To ensure real-time and consistency of the system, the three MP modules utilize TriBus - a high-speed, fault-tolerant inter processor bus - to compare their respective data during each scan. At the same time, MP communicates with the I/O module through a TMR HDLC I/O bus running at a rate of 2 megabits per second. In terms of physical structure, the MP motherboard not only provides module installation interfaces, but also is equipped with redundant 24 volt fuse logic power connectors, which can directly power the MP module and transfer the logic power to the I/O motherboard, simplifying power wiring.

The front panel design of the MP module is highly user-friendly and integrates a variety of status indicators. For example, the "Field Power" alarm indicator is used to indicate the loss or failure of power supply on site; The 'Logic Power' alarm indicator indicates a loss or malfunction of the system power supply; System Alarm "indicates application issues or compromised system integrity. In addition, there is a "Pass" indicator used to indicate that the processor is in normal working condition, an "Active" indicator that flashes when executing applications, and a "Fault" indicator used for fault detection.

2. Communication module

The communication module serves as a three to one interface between MP and the external world. A single Trident controller can support up to two CM modules on a CM motherboard, with each module running independently. This configuration can achieve redundant communication connections or provide additional independent communication ports.

The CM module supports a wide range of industrial communication protocols, including communication with external host computers, distributed control systems (DCS), open networks, network printers, other Trident v2 systems, and even Tricon versions 9-10 systems.

In terms of interface configuration, each CM module provides three optically isolated RS-232 or RS-485 serial ports, which users can configure as Modbus point-to-point or multi-point network connections, with a maximum transmission rate of 115 kilobits per second. At the same time, each CM is equipped with two network ports: a 10 megabit Ethernet port (supporting 10BaseT and AUI interfaces) and a 100 megabit Ethernet port (supporting 100BaseTX and MII interfaces). This design allows the use of Media Adaptation Units (MAUs) to convert Ethernet media types or extend network distances.

The CM module also supports a wide range of protocols. The serial port supports Modbus master (RTU), Modbus slave (ASCII or RTU), and JetDirect network printer server DLC/LLC. The network ports support TSAA (UDP/IP), TSAA with IP Multicast (UDP/IP), TriStation, point-to-point communication (UDP/IP or DLC), Modbus TCP master/slave, Triconex time synchronization (UDP/IP or DLC), and SNTP.

I/O module system: Precision control of analog and digital

Trident's I/O modules follow a unified mechanical design principle, support hot standby function, and have mechanical fail safe keys to prevent accidental insertion. Each I/O module occupies one of the two slots on the motherboard, and the "L" and "R" labels on the motherboard indicate the position of the left and right modules, respectively. The module can be in an active or hot standby state on the base plate, supporting online replacement, greatly improving the maintainability of the system. The maximum operating environment temperature for all I/O modules is 158 ° F (70 ° C).

1. Analog input module

The Model 3351 analog input module consists of three independent isolated channels, each of which independently processes analog input signals from field devices. After processing, the data is transmitted to the associated MP, which then votes and sends it to the application. In TMR mode, the data passed is median; In dual-mode, it is the average value.

This module has comprehensive continuous diagnostic functions, which can detect and indicate any single channel fault, ensuring normal operation under a single fault, and even maintaining operation under multiple faults. Its technical specifications include 32 common points, supporting a nominal input current of 4-20mA DC, and an operating range of 2-22mA DC. The absolute maximum input voltage is 33VDC, and the reverse voltage is -0.6VDC. The input bandwidth (3dB) of the module is 16Hz, the source impedance is 180 ohms, the resolution reaches 12 bits, and the absolute error is less than 0.15% of the full scale. The scanning time is less than 1 millisecond (for all 32 points). In addition, the AI module is compatible with multiple substrates, including standard substrates, RTD/TC/4-20mA dedicated substrates, and substrates that support the HART protocol (including hazardous area types).

2. Analog output module

Trident's analog output module (AO) adopts Model 3481 standard or Model 3482 high current type. Each module has three isolated channels that independently receive MP data. It selects a single channel to drive the output through a voting circuit and short circuits other channels to prevent interference.

Model 3481 provides 4 common circuit and DC coupled isolation points, with an output range of 4-20mA (controllable) and overload capacity of 0-22mA. The output accuracy is less than 0.25% (FSR) within the range of 32 ° F to 158 ° F, with a resolution of 12 bits. The nominal value of the external circuit power supply is 24VDC, with a maximum of 32VDC. The Model 3482 supports high current outputs of 4-40mA on Points 3 and 4 to meet higher power requirements.

The AO module also has hot standby capability and is compatible with standard AO baseboards, HART AO baseboards, and dedicated baseboards for hazardous areas.

3. Digital input module

The Model 3301 digital input module independently processes digital signals through three isolated channels. Each channel transmits the processed data to the corresponding MP for voting. This architecture can effectively prevent a single channel failure from affecting other channels.

This module supports 32 common input points, with a nominal input voltage of 24VDC and an operating range of 15-30VDC. Input delay less than 10 milliseconds (on/off), equipped with Force to value diagnostics (FVD) function, and testing cycle less than 2 milliseconds. The input impedance is approximately 3 kiloohms with a backplane and greater than 30 kiloohms without a backplane. To ensure diagnostic coverage, the maximum switching frequency of input points should be less than 20 times per second.

The DI module is compatible with standard baseboards, external terminal baseboards for high-voltage applications, and specialized baseboards for hazardous areas, and can adapt to various harsh on-site environments.

4. Digital output module

The Model 3401 digital output module adopts proprietary Quad Voter circuit technology. This circuit is based on a parallel series path, and only allows output on/off when any two commands in the three channels (A, B, C) are closed. This design provides multiple redundancies on all critical signal paths, ensuring maximum safety and availability.

The DO module regularly executes the Output Voting Diagnosis (OVD) program, which can detect "adhesion" or "disconnection" faults at all points, as well as faults in related switches or drive circuits, within 500 milliseconds. Its specifications support multiple configurations, including standard type, low current type (with 180 ohm series resistance), and applications for high voltage or hazardous areas.

5. Hybrid and specialized modules

Trident also offers the Model 3361 analog/digital input hybrid module, which integrates 16 digital input points and 16 analog input points, suitable for applications with limited space. The Pulse Input (PI) module (Model 3381) is designed specifically for processing speed sensor signals, capable of converting voltage into frequency (RPM) data and supporting speed measurements up to 32000 RPM. The Solid State Relay Output (SRO) module is used for control of

Physical Structure, Interconnection, and Expansion

The physical layout of the Trident system emphasizes modularity and compactness.

1. Size and base plate

The dimensions of the MP motherboard, HART AI motherboard, and HART AO motherboard are 9 inches (229 millimeters) wide and 9.79 inches (249 millimeters) long. All types of I/O module baseboards have a width of 7.0 inches (178 millimeters) and the same length. All I/O modules have uniform physical dimensions: 8.65 inches (220 millimeters) high, 1.75 inches (44 millimeters) wide, and 6.65 inches (169 millimeters) deep.

2. I/O Expansion and Interconnection

To support large-scale distributed I/O, Trident introduced the I/O extender module kits. These kits are used to transfer I/O messages between different I/O columns and provide logical power terminals for each I/O column. In a typical system, a maximum of 8 baseboards are allowed to be connected end-to-end in a single I/O column. When exceeding this limit, I/O extender modules and I/O bus cables need to be used for expansion. The maximum allowable length of the I/O bus is 650 feet (200 meters), and termination kits must be added at both ends of the bus if it exceeds 20 feet.

The baseboards are connected through Interconnect Assemblies, which consist of PCBs with DIN-C 96 pin connectors for carrying I/O messages and logic power.

3. Attachments and Protection

In order to protect Trident components from dust, liquids, and corrosive gases, the system is equipped with necessary accessories, including End Caps (for column end protection), Terminal Cover (for protecting unused wiring terminals), and Slot Cover (for protecting unused slots).

Environmental adaptability and global compliance

1. Environmental specifications

The Trident system is designed specifically for harsh industrial environments. Its operating temperature range is -4 ° F to+158 ° F (-20 ° C to+70 ° C), and its storage temperature range can reach -40 ° F to+185 ° F (-40 ° C to+85 ° C). The system can withstand non condensing relative humidity of 5% to 95% and has passed the G3 level corrosion environment test defined by ISA S71.04 standard.

In terms of mechanical tolerance, the system can withstand sinusoidal vibrations of 1G @ 10 to 150 Hz per axis, as well as impacts of 15G per axis lasting 6-11 milliseconds. In terms of electromagnetic compatibility (EMC), Trident strictly follows the IEC 61000-4 series standards, including anti-static discharge (4kV contact/8kV air), radio frequency interference, electrical fast transient/pulse group, and surge immunity, ensuring stable operation in complex electromagnetic environments. Meanwhile, its conduction and radiation emissions comply with CISPR 16 and CISPR 11 Class A standards.

2. International certification

Trident controllers have been certified by multiple authoritative certification bodies worldwide and can be used for safety critical applications worldwide.

CSA (Canadian Standards Association): Certified to comply with multiple electrical safety standards including CAN/CSA-C22.2 No.0-M91, UL 3121-1, etc.

CE Mark (EU): Based on T Ü V assessment, compliant with EU EMC Directive 89/336/EEC and Low Voltage Equipment Directive 72/23/EEC. Note: To meet CE requirements, MP and CM modules must be installed inside a metal casing.

FM (Factory Mutual Assistance): Certified for use in Class I, Division 2, Temperature T4, Groups A, B, C, and D hazardous locations.

T Ü V Rheinland: Certified to comply with IEC 61508 (Functional Safety), EN50156-1 (Furnace Equipment), NFPA 85 (Boiler and Combustion Systems), SEMI S2-0200 (Semiconductor Equipment), and ATEX Directive (Explosion proof).

In summary, Trident controllers have become an ideal choice for industrial safety instrumented systems due to their precise triple redundant architecture, rich modular I/O options, strong environmental adaptability, and comprehensive international certifications. Whether dealing with harsh physical environments or meeting the highest level of functional safety standards, Trident has demonstrated outstanding reliability and professional performance.

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor

- SHINKAWA