Comprehensive Analysis of Siemens TP/OP 170 Series Touch Screen and Operation Panel

Technical Analysis and Application Guidelines for Siemens TP 170A, TP 170B, and OP 170B Operation Panels

In industrial automation systems, human-machine interface (HMI) is a key component for implementing equipment monitoring, parameter setting, and process intervention. The TP 170A, TP 170B touch screens, and OP 170B operation panels under the Siemens SIMATIC HMI series are classic products for mid to low end applications. With their reliable performance, flexible configuration, and strong environmental adaptability, they are widely used in industries such as mechanical manufacturing, packaging, automotive, and chemical. This article is based on the official equipment manual, systematically analyzing the technical architecture, functional configuration, installation, debugging, and maintenance points of these three devices, providing comprehensive application references for engineering and technical personnel.

Product Overview and Positioning

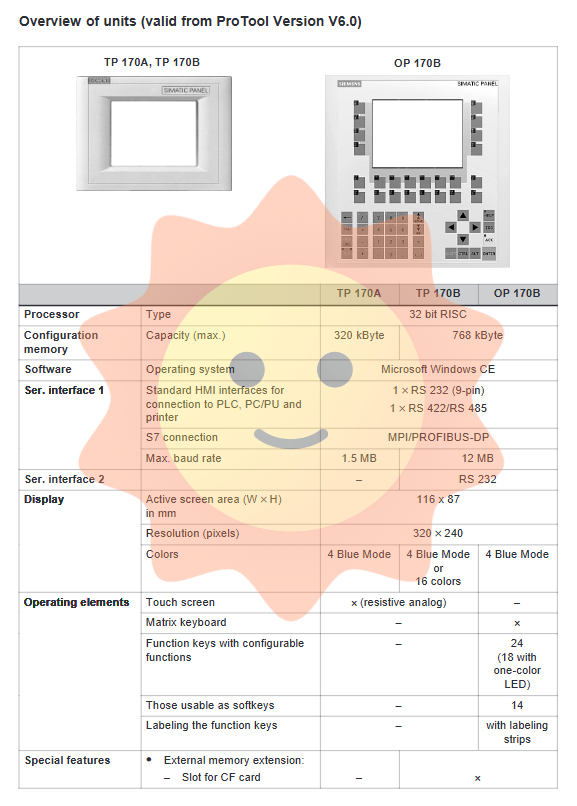

TP 170A, TP 170B, and OP 170B belong to the "Low end Units" in the SIMATIC HMI series, all using Microsoft Windows CE operating system, which combines cost-effectiveness and functional practicality. Among them, TP 170A is an economical entry-level product that supports all SIMATIC S7 series PLCs; On this basis, TP 170B and OP 170B have enhanced functions such as graphic display, message processing, and recipe management to meet more complex process monitoring requirements.

These three devices all have an IP65 front panel protection level and are designed without a hard drive or fan, making them suitable for direct installation in cabinets or workstations in harsh industrial environments such as dust and oil pollution. Its communication interface supports MPI, PROFIBUS-DP, and various third-party PLC protocols, making it easy to integrate into existing automation networks.

Hardware structure and core functions

1. Display and operation unit

TP 170A/TP 170B: Equipped with a 5.7-inch STN LCD screen, with a resolution of 320 × 240, supporting 4-level blue tone or 16 color display. The operation mode is a resistive touch screen that supports finger or stylus input.

OP 170B: Also a 5.7-inch screen, but equipped with an integrated film keyboard, including 35 system keys (including 3 with LED indicator lights) and 24 configurable function keys (including 18 with LEDs), suitable for scenarios with frequent data input and function calls.

2. Processor and Storage

The device is equipped with a 32-bit RISC processor and runs Windows CE system. The TP 170A has a configured memory of 320 KB, while the TP 170B and OP 170B have 768 KB. They support storage expansion through CompactFlash (CF) cards for recipe data, project backup, and more.

3. Communication interface

IF1A: RS232 serial port, used to connect programming units (PU/PC) or partial PLCs.

IF1B: Supports RS422/RS485 (electrical isolation) and can be configured as MPI or PROFIBUS-DP interface through dip switch.

IF2 (TP/OP 170B only): RS232 serial port, commonly used for connecting printers or configuring computers.

The power interface is a 2-pin terminal that supports 24 VDC safe extra low voltage (SELV) and has reverse polarity protection.

4. Summary of core functions

Screen objects: support text, graphics, input/output fields, buttons, status buttons, bar charts, trend views, message displays, recipe views, etc.

Message system: supports event messages, alarm messages (to be confirmed), and HMI system messages. TP/OP 170B also supports message buffering, printing, and archiving.

Recipe Management (TP/OP 170B only): It can create, edit, and store recipe data records, support transfer from/to PLC, and can be imported and exported through CSV files.

Multi language support: Up to 5 languages can be loaded, allowing for online switching of screen text, messages, and other content.

Password protection: Supports multi-level (0-9) password permission management to ensure operational security.

Configuration and Project Download

The device is configured through ProTool CS (including ProTool/Pro CS, ProTool/Lite). The configuration steps are as follows:

Project creation: Use ProTool CS to design graphics, define variables, and configure communication connections on the configured computer.

Communication settings: Connect HMI and PC through serial port or MPI/PROFIBUS interface. Select "Transfer" mode in the HMI startup menu and enable the corresponding channel and "Remote Control" option in "Transfer Settings" for automatic download.

Download project: Select "Download" in ProTool CS and transfer the compiled project file (. fwd) and running system to HMI. If you want to keep the source file for future modifications, you can check the "Upload" option and store the project in compressed format (. pdz) on the CF card of the HMI.

Testing and debugging: HMI can test the screen logic in offline mode and communicate with PLC in online mode. ProTool CS has a built-in simulator that can verify projects without hardware connection.

Installation and Wiring Guide

1. Mechanical installation

Installation hole size: TP 170A/TP 170B is 198 × 142 mm (tolerance -0/+4 mm), OP 170B is 229 × 241 mm.

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor

- SHINKAWA