Honeywell Touchpoint Plus Gas Detection and Control System

Honeywell Touchpoint Plus Gas Detection and Control System

Product Overview

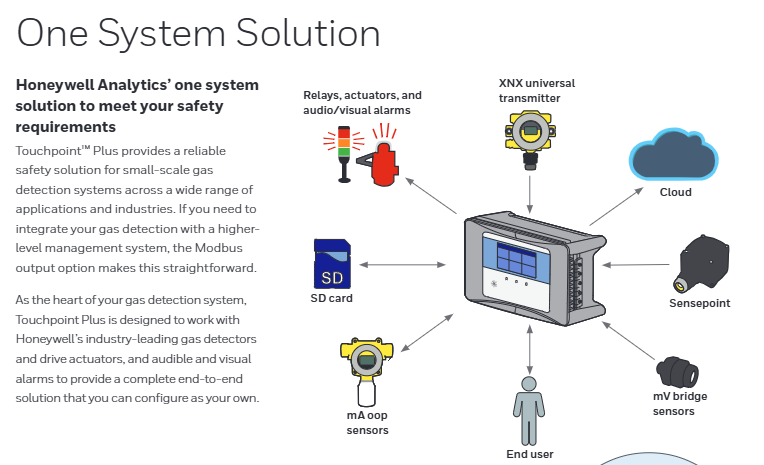

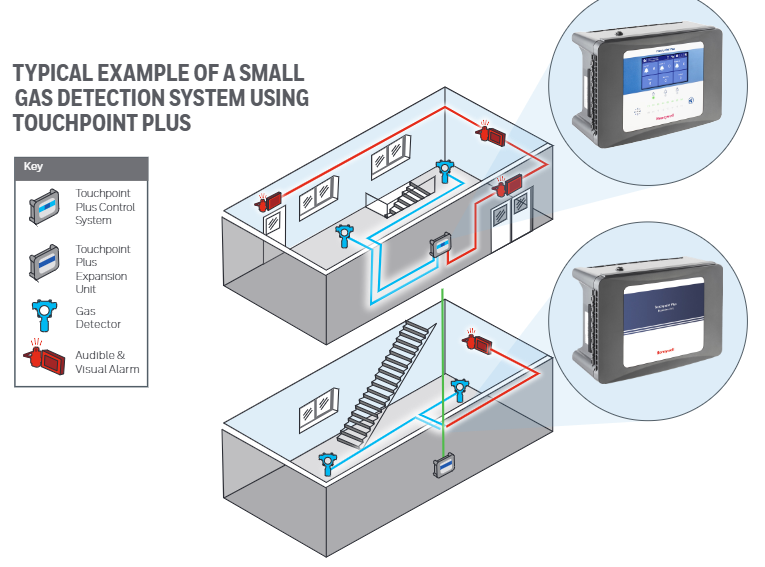

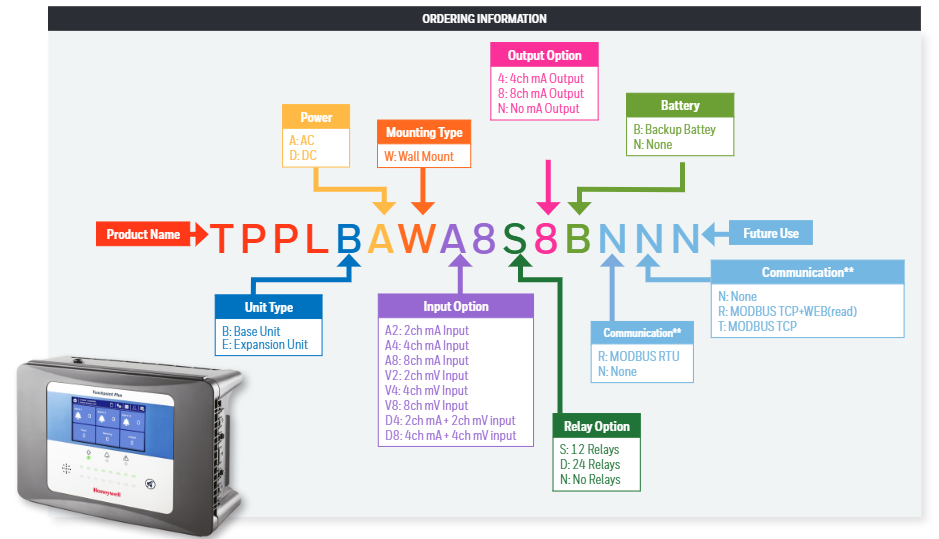

Touchpoint Plus is a wall mounted control center designed by Honeywell specifically for small gas detection systems, aimed at providing reliable gas safety monitoring solutions for industrial environments through modular design and intuitive operation. The system supports up to 16 gas detection channels (8 basic units, increased to 16 with expansion units), suitable for various scenarios such as mechanical workshops, chemical plants, laboratories, etc. The core advantage lies in the deep integration of reliability, flexibility, and usability.

Core functions and features

1. High reliability design

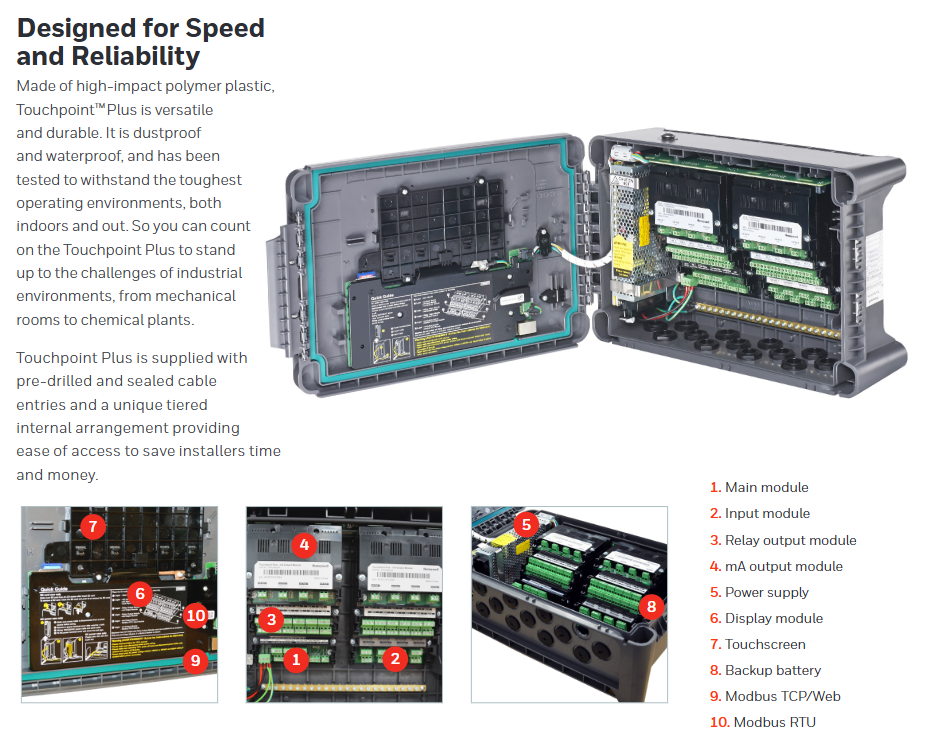

Industrial grade durability: The shell is made of polycarbonate ABS high impact polymer plastic, with dust and water resistance (IP65, NEMA 4X certification), and can operate stably in continuous working temperatures ranging from -10 ° C to+55 ° C (humidity ≤ 95% non condensing) and harsh vibration environments, suitable for complex indoor and outdoor industrial scenarios.

Continuous operation guarantee: Equipped with a built-in 22.2V lithium battery (2600mAh), it can provide backup power for more than 30 minutes under typical systems, avoiding monitoring interruptions caused by sudden power outages.

Compliance certification: Compliant with multiple international safety standards, including electromagnetic compatibility (EN 50270:2015), electrical safety (UL 61010-1), safety integrity (IEC 61508:2010 Ed.2 SIL2), and applicable to Class I, Division 2 and other hazardous areas, ensuring safe use in flammable and explosive environments.

2. Flexible system configuration and compatibility

Modular Expansion:

The basic unit supports 2/4/8 channel inputs (mA or mV signals), and the expansion unit can increase the total number of channels to 16, meeting the detection needs of different scales.

Rich output options: 12/24 relay outputs (supporting NO/C/NC switching, 1.7A@30VDC /250VAC)、 4/8-channel 4-20mA isolated output, capable of driving valves, fans, and other equipment or linking external alarm systems.

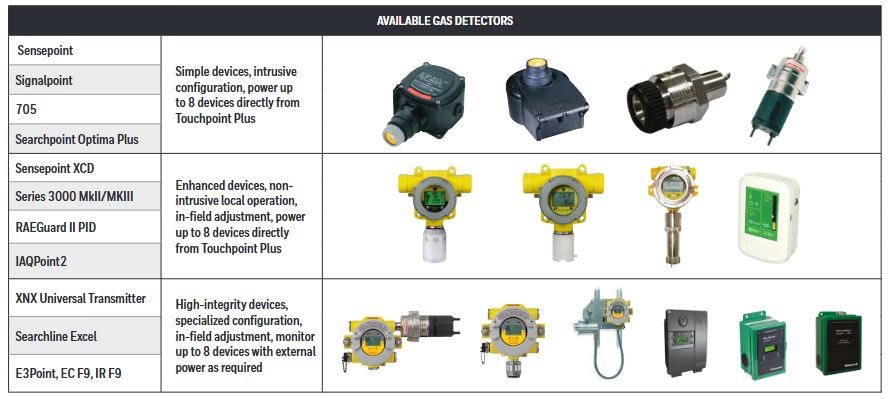

Wide compatibility: Compatible with Honeywell's full range of gas detectors, including:

Basic type: such as Sensepoint (supporting direct power supply for 8 devices, requiring invasive configuration);

Enhanced: such as Sensepoint XCD (non-invasive operation, supports on-site calibration, can directly power 8 units);

High precision type: such as XNX Universal Transmitter (requires external power supply, supports professional configuration and on-site debugging).

System integration capability: Optional RS485 Modbus RTU or TCP/IP Modbus/HTTP interfaces are available for easy integration with upper level management systems such as SCADA and DCS, enabling remote monitoring and data integration.

3. Humanized operation and efficient management

Intuitive user interface:

7-inch color LCD touch screen, equipped with a graphical user interface, supports 9 languages including English, Chinese, French, etc., reducing the threshold for cross regional operation.

Both global and single channel are equipped with green yellow red three color indicator lights (green=normal, yellow=fault/suppression, red=alarm), which can quickly identify the system status from a distance, similar to the logic of "traffic lights", improving emergency response efficiency.

Convenient function design:

Built in sound alarm (≥ 70dB@1 Equipped with remote sound and light alarm drivers, it ensures timely transmission of danger signals.

Support remote reset, suppress input, and quickly intervene in system status through external signals (such as temporarily blocking non critical alarms).

Data recording function: Store configuration parameters, alarm events, and historical data through SD card for easy traceability and analysis, and assist in optimizing security policies.

4. Convenient installation and maintenance

Simplified installation process:

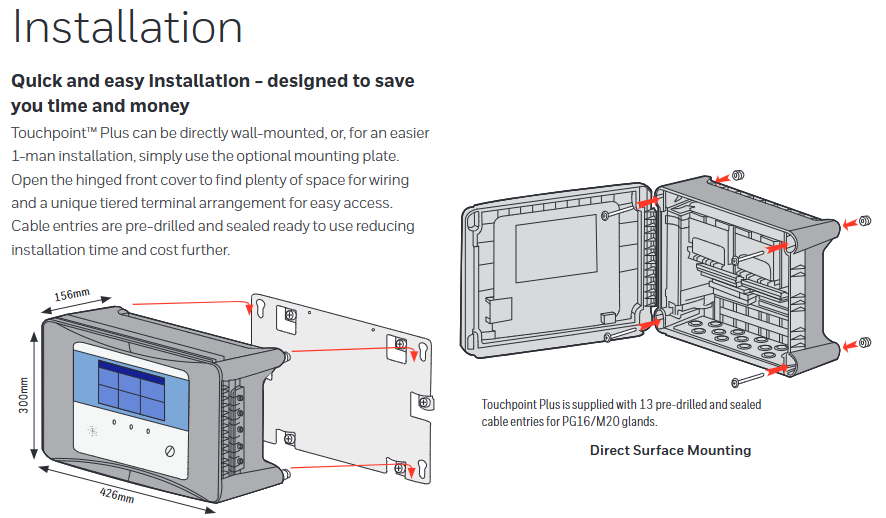

Supports direct wall mounting or optional installation board (can be installed by a single person), with 13 sealed cable entrances preset in the housing (compatible with PG16/M20 connectors), reducing on-site drilling and sealing work.

Internally, a layered terminal design is adopted, providing ample wiring space for distinguishing power, signal, and output lines, reducing wiring error rates.

Low maintenance cost: Modular components (such as input modules and relay modules) can be independently replaced, and troubleshooting does not require a complete shutdown; Channel status and diagnostic information can be directly viewed through the touch screen, reducing reliance on professional tools.

Technical specifications

Channel capacity: Basic unit has 8 channels, expansion unit supports up to 16 channels

Input type: 2-wire/3-wire system, supports mA (4-20mA), mV (bridge signal), single channel maximum 15W, total power 40W (with sound and light drive)/68W (without)

Power supply AC: 110/220V (50-60Hz, manual switching); DC 18-32V (typical 24V, ± 10% fluctuation)

Power consumption: Maximum 105W (including detector and peripherals), total power consumption of expansion unit is maximum 210W

Size and weight: 426mm x 300mm x 156mm (wall mounted); Maximum 8.5kg (single unit), 17kg (including expansion unit)

Environmental adaptability: Operating temperature: -10 ° C~+55 ° C, storage temperature: -25 ° C~+60 ° C; humidity ≤ 95% (non condensing)

Communication interface: optional Modbus RTU (RS485), Modbus TCP/HTTP, supports web monitoring

Applicable scenarios

Typical applications: Small chemical workshops, gas boiler rooms, laboratory gas leak monitoring, pharmaceutical cleanrooms, and other scenarios that require centralized management of multi-point gas detection.

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor

- SHINKAWA

- Other Brands