Triconex Tricon v9-v11 fault-tolerant control system: triple module redundant architecture and high availability design

System configuration and modular component ecosystem

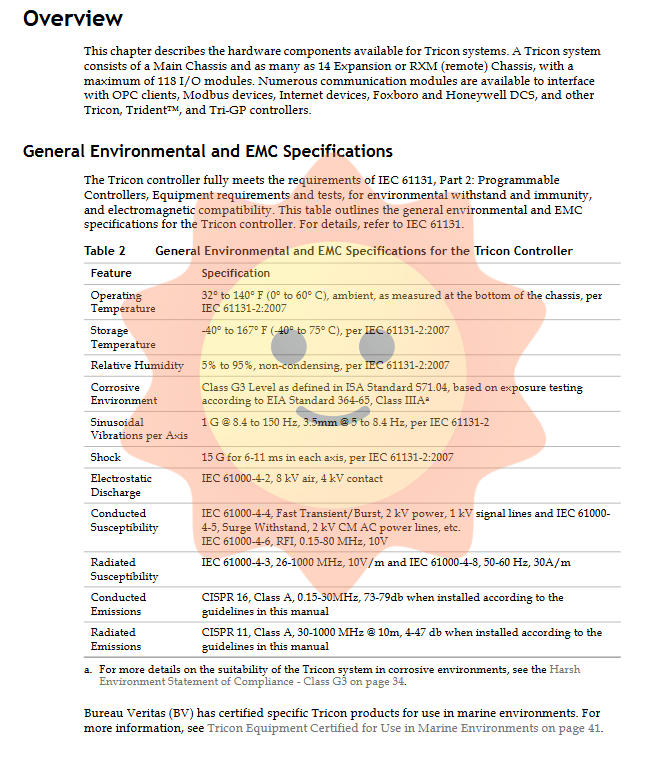

A complete Tricon system consists of one main rack and up to 14 expansion racks or remote expansion racks, supporting up to 118 I/O modules and communication modules. The system configuration follows strict rules to maximize reliability and availability.

2.1 Rack Layout and Power Redundancy

There are two power modules installed on the left side of all racks, using a dual redundancy configuration. Each module has the ability to independently supply power to all modules in the rack and supply power to two independent power rails on the backplane. This design ensures that any power failure will not affect system performance. On the right side of the power module in the mainframe, there are three main processors. The rest of the host is divided into six logical slots for installing I/O and communication modules, as well as a communication (COM) slot without a hot spare position. The layout of the expansion rack is similar, but it provides eight logical slots for the I/O modules.

In addition, the Tricon v11 series also introduces high-performance host racks (such as the 8120E), which support higher speed main processors (such as the 3009) and unified communication modules (UCM). In the 8120E rack, the TriBus speed can reach 1000 Mbps, significantly improving the system's data throughput and response speed in large and complex applications.

2.2 Rich family of I/O and communication modules

Tricon offers an extremely comprehensive module product line to meet various application needs.

Digital quantity module: Provides multiple digital input modules, including TMR (Triple Redundancy) and single module. The TMR digital input module supports self checking to detect the "stuck ON" state, which is crucial for implementing a safety system with "disabled tripping". There are various types of output modules, including dual channel, supervisory, DC, and AC voltage modules. The supervised digital output module is designed specifically for outputs that require long-term maintenance of a single state, with complex online diagnostic functions that can detect on-site faults such as power outages, fuse failures, load loss, or short circuits.

Analog module: including analog input and output modules. The analog input module measures asynchronously through three channels and uses the median selection algorithm. Supports multiple signal types, such as 0-5VDC, 4-20mA, as well as thermocouples and thermistors. The analog output module continuously checks the correctness of the output by reading back the input, and automatically switches to other channels when the drive channel fails.

Communication module: Provides multiple interfaces to connect different host systems and networks.

Tricon Communication Module (TCM): Compatible with v10.0 and later systems, supports Ethernet (802.3) and serial (RS-232/RS-485) communication, and can be used for Modbus master/slave devices, TriStation programming tools, GPS clock synchronization, and network printing.

Enhanced Intelligent Communication Module (EICM): Supports serial communication, interfaces with Modbus master/slave devices, TriStation, and printers.

Network Communication Module (NCM): Supports Ethernet communication for Triconex proprietary protocols and applications, and supports OPC servers.

Advanced Communication Module (ACM): serves as an interface with the Foxboro Intelligent Automation I/A Series Distributed Control System.

Safety Management Module (SMM) and High Speed Interface Module (HIM): used to connect Honeywell General Control Network and Data High Speed respectively, achieving integration with TDC 3000 DCS.

2.3 Remote Expansion (RXM) and Long Distance Transmission

The Tricon controller supports placing I/O at a distance of up to 7.5 miles (12 kilometers) from the host rack using RXM (Remote Expansion Module) and SRXM (Single Mode Fiber) modules. The RXM rack can contain one RXM module set and six logical slot I/O modules. Multimode fiber optic cables can be used to support three remote RXM racks or expansion racks, while single-mode fiber optic cables support one remote rack. This remote expansion capability provides great flexibility for decentralized on-site layout, while ensuring excellent electromagnetic interference resistance through fiber optic transmission.

2.4 On site wiring options

To facilitate on-site wiring and allow for replacement of I/O modules without interfering with on-site wiring, Tricon offers two options: external wiring panel and fan out cable. ETP is an electrically passive printed circuit board, and on-site wiring can be easily connected to its terminal blocks. Fan out cable is a low-cost alternative solution, with one end connected to the Tricon rack backplane and the other end providing 50 fan out leads. The system also provides multiple options including a wiring panel with isolation relays, a digital input bypass panel, and an explosion-proof wiring panel for hazardous locations.

Communication capability and network integration

The Tricon controller is not only a fault-tolerant execution unit, but also a powerful communication hub that supports multiple industry standard protocols and can seamlessly integrate with upper level management systems and other security systems.

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor

- SHINKAWA