Woodward EM-80/EM-300 Electric Actuator Specification Guide

Compliance with major maritime classification societies (ABS, BV, LR, RMRS) and rigorous environmental testing (shock, vibration, humidity) makes these actuators suitable for the harshest environments found on ships and offshore platforms. The elimination of hydraulic oil not only simplifies the maintenance schedule but also eliminates a significant environmental hazard. Whether applied to a large diesel generator set or a steam turbine governor, the EM-80/EM-300 series stands as a cost-effective, high-performance solution for modern rotary actuation needs.

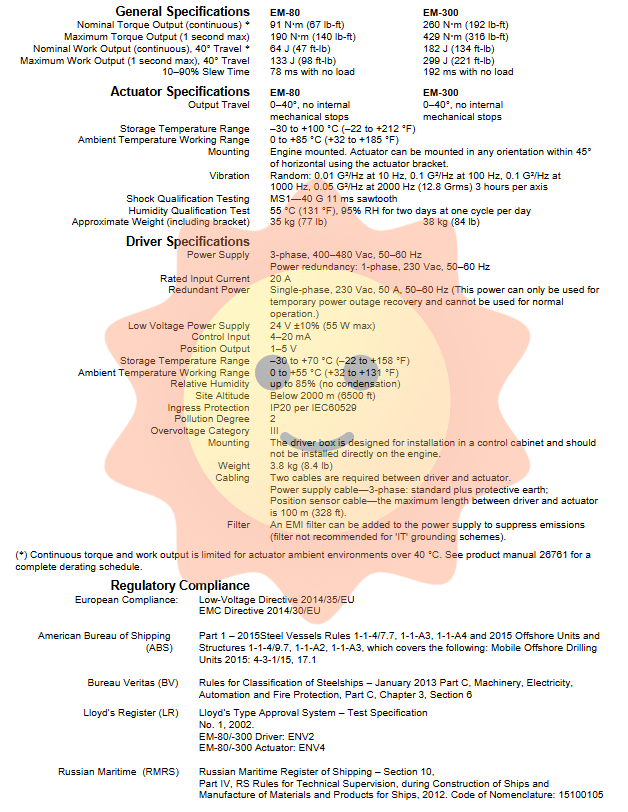

Nominal Work Output (Continuous, 40° Travel): EM-80 is 64 J (47 ft-lb); EM-300 is 182 J (134 ft-lb).

Maximum Work Output (1 second max, 40° Travel): EM-80 is 133 J (98 ft-lb); EM-300 is 299 J (221 ft-lb).

*Implication:* The work output rating helps engineers calculate the energy capacity of the actuator, ensuring the system can perform the required mechanical work (moving the fuel rack from idle to full power) without overheating during the stroke.

4. 10–90% Slew Time

Slew time is the speed at which the actuator can rotate, measuring the time taken to move from the 10% position to the 90% position.

EM-80: 78 ms with no load.

EM-300: 192 ms with no load.

*Implication:* The EM-80 is a “fast” actuator. Its sub-100ms slew time makes it ideal for applications requiring rapid governing to maintain frequency stability or transient response. The EM-300 is slower but compensates with its higher torque. This highlights the classic engineering trade-off: the EM-80 trades torque for speed, while the EM-300 trades speed for torque.

Actuator Mechanical Specifications

The physical characteristics of the actuator dictate how it integrates with the engine mounting structure.

1. Output Travel

Both the EM-80 and EM-300 provide a fixed rotation range of 0–40 degrees. Crucially, there are no internal mechanical stops. This design choice places the responsibility on the external mechanical linkage (engine fuel rack) to define the hard stops. This prevents the actuator from driving itself against an internal wall, which could damage the gearbox, but requires the installer to ensure the external linkage has adequate travel limits.

2. Temperature Ratings

Storage Temperature Range: –30 to +100 °C (–22 to +212 °F). This wide range ensures the units can be shipped and stored in extreme environments without degradation.

Ambient Temperature Working Range: 0 to +85 °C (+32 to +185 °F). This robust operating range allows installation on engines in hot engine rooms or in climates where ambient heat is significant.

3. Mounting and Orientation

The actuators are designed to be engine-mounted. They can be mounted in any orientation provided they are within 45° of horizontal using the actuator bracket. The included bracket design ensures that stresses in the actuator are minimized by providing a rigid, pre-drilled interface. The specifications note that actuator performance is based on installation that includes this bracket; using alternative mounting methods may alter stress profiles and affect durability.

4. Shock and Vibration

Given the harsh environment of diesel engines, vibration and shock resistance are paramount.

Vibration Qualification: Random vibration profile: 0.01 G²/Hz at 10 Hz, rising to 0.1 G²/Hz at 100 Hz, sustained at 0.1 G²/Hz at 1000 Hz, and tapering to 0.05 G²/Hz at 2000 Hz. The test is performed at 12.8 Grms (Root Mean Square) for 3 hours per axis. This rigorous testing ensures the actuator’s internal electronics and mechanical components remain intact despite the constant shaking of a running engine.

Shock Qualification Testing: MS1–40 G 11 ms sawtooth. This simulates sudden impacts, such as a rough sea state for marine engines or a sudden emergency shutdown event.

5. Weight and Dimensions

EM-80 Weight: Approximately 35 kg (77 lb) including the bracket.

EM-300 Weight: Approximately 38 kg (84 lb) including the bracket.

The small weight difference suggests the majority of the mass is in the motor and housing, with the gear ratio change in the EM-300 adding minimal mass but significant mechanical advantage.

6. Humidity

The system is qualified to withstand 55 °C (131 °F) at 95% Relative Humidity for two days, undergoing one cycle per day. This ensures moisture ingress will not cause corrosion of the internal electronics or mechanical seizure.

Driver Unit Specifications

The driver unit, separate from the actuator, houses the power electronics and logic.

1. Power Supply

Main Power: The driver requires a 3-phase, 400–480 Vac, 50–60 Hz power source. This industrial standard voltage is typically available in plant and marine environments.

Redundant Power: The system supports a power redundancy feature utilizing 1-phase, 230 Vac, 50–60 Hz. It is critical to note that this redundant power is rated for 50 A, but can *only* be used for temporary power outage recovery and cannot be used for normal operation. This feature allows the engine to maintain control during a brief loss of the main 3-phase supply, preventing an immediate engine trip.

2. Rated Input Current

The driver draws a significant current to maintain actuator performance:

Normal Operation: 20 A.

Redundant Mode: 50 A on the single-phase backup line. The higher amperage in single-phase mode reflects the need to draw equivalent power from a reduced number of phases.

3. Low Voltage Power Supply

The logic and control circuits operate on a 24 V ±10% supply, with a maximum power rating of 55 W. This separates the sensitive logic from the high-voltage motor drive, enhancing reliability and safety.

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor

- SHINKAWA