How to install the Rockwell Automation 1756 series ControlNet communication module?

Model Core Features Applicable Scenarios

1756-CN2 standard media (non redundant), conventional industrial environment without anti-corrosion coating, single network link

1756-CN2K standard media (non redundant), with anti-corrosion coating (model ending with "K" mark), corrosive industrial environment (such as chemical and metallurgical)

1756-CN2R redundant media (dual link A/B), high reliability demand scenario without anti-corrosion coating (such as energy, transportation)

1756-CN2RK redundant media (dual link A/B) with anti-corrosion coating and high reliability requirements scenario

1756-CN2RXT redundant media, wide temperature design (-25~70 ℃), without anti-corrosion coating for extreme temperature environments (such as outdoor and refrigerated)

How to install the Rockwell Automation 1756 series ControlNet communication module?

Product Family and Core Positioning

1. Model classification and functional differences

The 1756 series ControlNet module is divided into "media type", "corrosion resistance", and "temperature adaptation range" to meet the needs of different industrial scenarios. The specific model functions are as follows:

Model Core Features Applicable Scenarios

1756-CN2 standard media (non redundant), conventional industrial environment without anti-corrosion coating, single network link

1756-CN2K standard media (non redundant), with anti-corrosion coating (model ending with "K" mark), corrosive industrial environment (such as chemical and metallurgical)

1756-CN2R redundant media (dual link A/B), high reliability demand scenario without anti-corrosion coating (such as energy, transportation)

1756-CN2RK redundant media (dual link A/B) with anti-corrosion coating and high reliability requirements scenario

1756-CN2RXT redundant media, wide temperature design (-25~70 ℃), without anti-corrosion coating for extreme temperature environments (such as outdoor and refrigerated)

2. Core advantages of ControlNet network

The ControlNet network connected to the module combines I/O network and Peer to Peer network functions, with the core features of:

Deterministic communication: ensuring repeatable and low latency transmission of critical control data;

Support redundancy: Redundant models (CN2R/CN2RK/CN2RXT) achieve network fault redundancy switching through dual links (A/B) to improve system stability.

Environmental requirements and safety certification

1. Basic environmental standards

Pollution level: only applicable to industrial environments with pollution level 2 (defined by IEC/EN 60664-1, which means the air contains only a small amount of non-conductive dust);

Overvoltage category: Class II application (IEC/EN 60664-1), suitable for downstream equipment in industrial distribution systems;

Altitude: up to 2000 meters (6562 feet), no need to downgrade for use;

Installation form: Open device, to be installed in an enclosure that meets the following requirements:

Protection level: at least IP54 (EN/IEC 60529);

Flame retardant rating: Non metallic shells must meet a 5VA flame spread rating;

Operation restriction: Tools are required to open the inside of the casing to prevent personnel from coming into contact with live parts.

2. Hazardous Area Certification

The module has been certified for hazardous areas in multiple regions, and the requirements for different regions are as follows:

Core requirements for certification areas

North America (Class I, Div 2) is suitable for A/B/C/D hazardous areas (such as environments containing flammable gases), with a temperature code of T4;

It is strictly prohibited to plug in or unplug modules/wiring in non power off or unknown non hazardous areas;

Components cannot be replaced, otherwise they may compromise their suitability for hazardous locations.

ATEX/UKEX equipment group II, category 3, protection type "Ex ec IIC T4 Gc" (increased safety type);

Only applicable to Zone 2 hazardous areas (where explosive gas environments rarely occur or occur in the short term);

It needs to be used with a UKEX/ATEX certified casing (IP54 or above).

IECEx certification protection type is the same as ATEX (Ex ec IIC T4 Gc), suitable for Zone 2 hazardous areas;

Transient protection must be met (peak voltage at the power supply end ≤ 140% of the rated value).

3. Requirements for electrostatic protection

The module is sensitive to static electricity, and the following should be followed during operation:

Contact with grounded objects to release static electricity, or wear a grounded wristband;

Do not touch module connectors, pins, and internal circuits;

When not in use, it should be stored in anti-static packaging;

Prioritize using anti-static workbenches.

Installation and wiring operations

1. Preparation before module installation

Slot position: Supports any size of ControlLogix chassis and can be installed in any slot (ensuring sufficient power capacity);

Redundant system requirements: The primary/backup modules need to be installed in the same slot of the corresponding chassis (such as the primary module in slot 3, and the backup module also needs to be in slot 3 of the backup chassis).

Network address setting:

Address range: Independent chassis modules range from 01 to 99, redundant chassis modules range from 01 to 98 (00 is an invalid address, only used for resetting);

Setting method: Adjust through the two digit dip switch on the side of the module (ten digits on the left and one digit on the right), ensuring that the address is unique within the same network.

2. Module installation and disassembly steps

(1) Installation steps

Confirm that the power supply of the chassis has been disconnected (power must be cut off in hazardous areas, and normal environments can support live plugging, but it is not recommended);

Align the module circuit board with the upper and lower rails of the chassis, and smoothly push it into the backplane connector;

Confirm that the module is flush with the power/other modules and not loose (do not forcefully press to avoid damaging the connector).

(2) Disassembly steps

Press the upper/lower tabs on both sides of the module to unlock it;

Smoothly slide the module out of the chassis, and power off in hazardous areas first.

3. ControlNet network wiring (Tap connection)

The module needs to be connected to the network through a ControlNet tap (Tap, such as 1786-TPR/TPS/TPYR/TPYS/TCT2BD1), with the following specific requirements:

Media type wiring method

Non redundant (CN2/CN2K) only connects the tap to module A channel (B channel is not used), and the tap needs to be selected as a direct connection type (such as 1786-TPS) to adapt to the BNC interface at the bottom of the module

Redundant (CN2R/CN2RK/CN2RXT) tap A is connected to module A channel, and tap B is connected to module B channel; Dual links need to be simultaneously connected to the network backbone (Trunk Line A/B)

Key wiring precautions:

Unused ports (such as the B channel of CN2) need to retain protective plugs (pre installed with the "K" model) to ensure the anti-corrosion level;

When the tap changer is disconnected from the module, it is necessary to immediately cover it with a dust cap to prevent the metal part from contacting the grounding surface;

In a redundant system, the main/backup modules need to be connected to the same network segment (such as the main module A channel connected to Trunk A, and the backup module A channel also needs to be connected to Trunk A).

4. USB port usage specifications

The module is equipped with a USB 2.0 Type B port, which is only used for temporary local programming. Core limitations:

Prohibited from use in hazardous areas;

Cable length ≤ 3 meters (9.84 feet), cannot be connected to a USB hub;

RSLinx Classic 2.55 and above software must be installed;

It is prohibited to upgrade multiple module firmware through USB at the same time to avoid upgrade failure.

Module reset and troubleshooting

1. Restore factory settings (reset operation)

When a module needs to clear configuration or fix exceptions, the following steps can be performed:

Disconnect the power supply of the chassis and remove the module;

Set the dip switch to "00" (invalid address, only used for reset);

Reinstall the module and connect the power supply;

After the module displays "Reset Complete Change Switch Settings", disconnect the power and remove the module;

Return the dip switch to the target address (01~99/98), reinstall and power on.

2. Core methods for troubleshooting

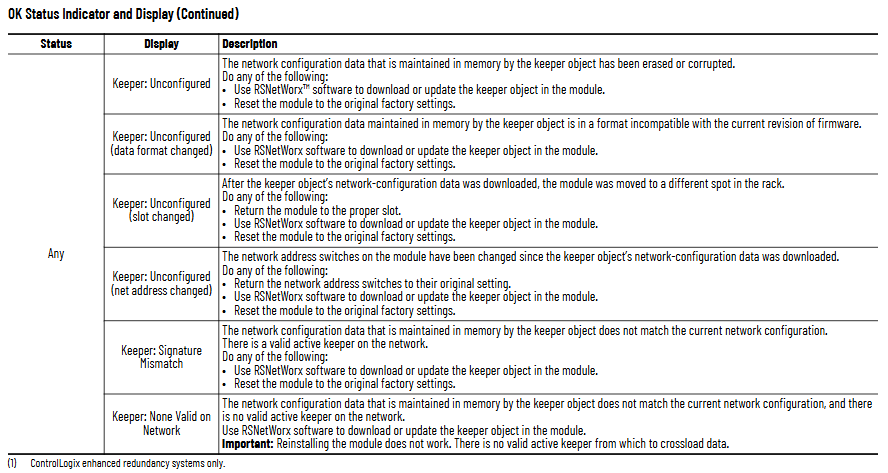

By using the OK status indicator light and network channel indicator light (A/B) of the module to locate the fault, the key status interpretation is as follows:

(1) OK status indicator light (core fault diagnosis)

Reason and solution for malfunction of indicator light status display information

Turn off power failure or internal failure: Check the power connection and module for tightness. If it is ineffective, replace the module

Reset Complete Change Switch Settings address to 00 (invalid): Reset valid address (01~99/98)

Frequent red FAIL power on test failure: replace module directly

Flashing red DUPLICATE NOTE DETECTED Network address conflict: Replace with unique address

Flashing red Image update Needed firmware needs to be updated: Use ControlFLASH software to upgrade Boot image

Evergreen/Blinking Green CPU=xx% (xx ≥ 80) CPU utilization is too high (over 80%): Check the number of network connections and optimize the control program

Blinking green NET ERR network wiring error or no other nodes: Check cables, terminators, and ensure that at least one other node is online

(2) Network channel indicator light (A/B channel status)

Interpretation of indicator light status channel (A/B) status

Evergreen is operating normally, and channel communication is functioning properly

Flashing green/extinguishing temporary error, module can self recover

Flashing red/off media malfunction (such as disconnection, looseness) or no other nodes: Check cables, terminators, and add online nodes

Constant red channel fault: power off reset module, if ineffective, contact Rockwell technical support

Key technical parameters

Parameter category 1756-CN2/CN2K 1756-CN2R/CN2RK 1756-CN2RXT

Backboard current 1.1A (5.1V DC) 1.3A (5.1V DC) 1.3A (5.1V DC)

Working temperature: 0~60 ℃ (32~140 ℉) 0~60 ℃ (32~140 ℉) -25~70 ℃ (-13~158 ℉)

Isolation voltage 30V DC (continuous), basic insulation between ControlNet/USB and backplane (500V AC withstand voltage for 60 seconds) on the same left (redundant models additionally support A/B channel isolation) on the same left

Anti corrosion grade (with "K") ASTM B845-97 G3 grade (ANSI/ISA 71.04), IEC 60721-3-3 CX grade same as left

The wiring category for ControlNet ports is Class 1, and for USB ports it is Class 3. Same as left

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor

- SHINKAWA

- Other Brands