Rockwell Automation 1794 Series FLEX I/O Digital Input Module

Rockwell Automation 1794 Series FLEX I/O Digital Input Module

Product Overview and Installation Preparation

(1) Product Core Information

Functional positioning: The 1794 series module is a FLEX I/O digital input module used for collecting digital signals (such as sensor and switch status) in industrial automation systems. It is transmitted through Flexbus in conjunction with terminal bases and supports 2-wire/3-wire input devices. Different models correspond to different input channel numbers (8/16/32 channels).

Hardware composition: The module needs to be installed on the 1794 series terminal base (such as 1794-TB3, 1794-TB32, etc.), and the core components include Flexbus connectors (for communication with adjacent bases/adapters), locking mechanisms (fixed modules), key switches (for base configuration), and status indicator lights (yellow, corresponding to the signal status of each input channel).

(2) Preparation before installation

Compatibility confirmation: It is necessary to use a specified communication adapter to ensure normal functionality. For example, 1794-IB32/IB32K requires the use of Remote I/O 1794-ASB (E series and above), ControlNet 1794-ACN15 (C series, firmware 4.1 and above), etc; Programming requires the use of Studio 5000 Logix Designer V20 or higher versions.

Tools and materials: Prepare suitable screwdrivers (for fixing terminal base screws), anti-static tools (grounding wristbands, anti-static cloth), wires that meet specifications (referring to terminal base requirements, usually 22-14 AWG shielded copper wire), DIN rails (made of galvanized chromate passivated steel material to ensure good grounding and avoid poor conductors such as aluminum/plastic).

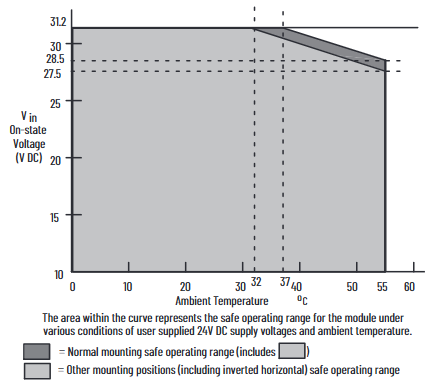

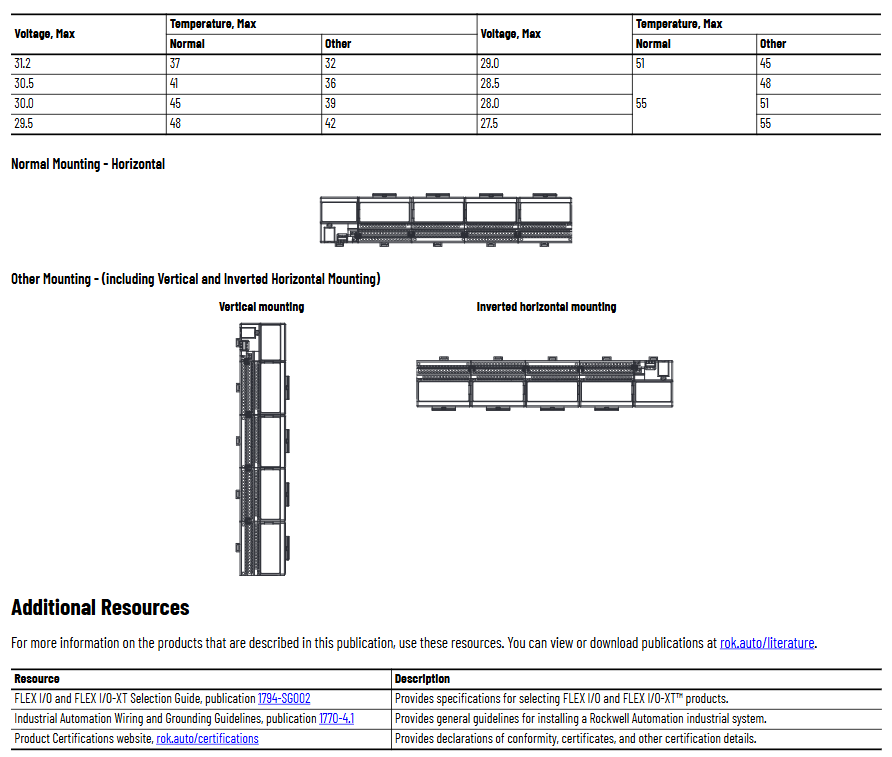

Environmental inspection: Confirm that the installation environment meets the requirements - pollution level 2 (industrial environment), overvoltage category II (EN/IEC 60664-1), altitude ≤ 2000 meters (no need to reduce capacity), and working temperature matching model (IB8/IB16 is -20~+55 ℃, IB32/IB32K is 0~+55 ℃).

Installation and wiring steps

(1) Module installation process

Base configuration: Rotate the key switch (position 3) on the terminal base to the "2" position (corresponding to the module type), ensuring that the Flexbus connector is fully pushed to the left and properly docked with the adjacent base/adapter.

Module alignment: Check if the pins at the bottom of the module are straight, align the alignment rod (position 6) of the module with the groove of the base (position 5), press the module evenly until the locking mechanism (position 2) clicks into the base, and confirm that the module is securely attached to the base.

Cleaning and inspection: During installation, avoid metal debris and wire residue from falling into the module to prevent short circuit damage after power on; After installation, check if all connections are secure and if the pins are not bent.

(2) Wiring method by model

1. 1794-IB8/IB16 (with 1794-TB3/TB3S base)

Wiring steps and operation details

Connect the signal line of the input device to the corresponding terminal of "A row (0-15)" (e.g. Input 0 is connected to A-0, Input 1 is connected to A-1)

Connect the+V DC power cord of the input device to the corresponding terminal of "C row (34-51)" (such as Input 0 connected to C-35), and all+V terminals in C row are internally connected; Connect the DC common terminal (3-wire device) to the corresponding terminal of "B row (16-33)" (such as Input 0 connected to B-17), and the B row common terminal is internally connected

Main power connection+V DC connection C-34, DC common terminal B-16

If the daisy chain extension needs to supply power to the next base, use jumper wires to connect the current base C-51 (+V) to the next base C-34, and B-33 (common terminal) to the next base B-16

2. 1794-IB32/IB32K (with 1794-TB32/TB32S base)

The module is divided into two sets of inputs (0-15, 16-31) and requires independent wiring:

Input 0-15: Connect the signal line to "A row (0-15)",+V1 to C row 35/37/39/41, COM1 to C row 36/38/40/42;

Input 16-31: Connect the signal line to "B row (17-32, skip 16/33)",+V2 to C row 43/45/47/49, COM2 to C row 44/46/48/50;

When expanding,+V1 jumps to the next base power terminal through C-41, and COM1 jumps to C-42; +V2 jumps through C-49, COM2 jumps through C-50.

(3) Wiring precautions

2-wire devices only need to connect the signal line and power line, while 3-wire devices require an additional connection to the common terminal;

The insulation layer of the wire needs to be stripped to a suitable length (to avoid short circuits caused by excessive exposure), and the torque of the terminal screws needs to meet the requirements of the base (usually 0.6-0.8 Nm);

Grounding needs to be achieved through DIN rails, which are fixed every 200 millimeters. End anchors need to be installed at both ends to ensure continuous grounding and low impedance.

Module configuration method

(1) Core configuration parameters

The module sets the input filtering time through the "configuration word (handwriting)", and the memory mapping and filtering control bits are different for different models. The core adjusts the signal stability through the "input filtering time (FT)" to avoid interference and false triggering.

(2) Filter time setting

Filter time options: selected through 3 binary bits (FT0-FT2), default 0.25 ms, optional 0.5 ms, 1 ms, 2 ms, 4 ms, 8 ms, 16 ms, 32 ms (see Table 6 for specific correspondence).

Configuration position by model:

1794-IB8: The filtering control bit corresponds to the 0-2 bits of "Write 1" and controls all 8 input channels;

1794-IB16: Control Input 0-11 with 0-2 bits, Input 12-15 with 3-5 bits, and support counter function (Input 15 can be set as fast input/standard input, and needs to be configured through CF/CR bits);

1794-IB32/IB32K: The filtering control bit corresponds to bits 8-10 of "Write 1" and controls all 32 input channels.

Configuration example: If you need to set the filtering time of 1794-IB8 to 4 ms, you need to write binary "101" (corresponding to decimal 5) to the "Write 1" address at system startup to ensure that the filtering parameters take effect after the module is powered on.

Technical specifications and certification

(1) Core electrical specifications

Model Number of input channels Rated voltage Conducting current (typical) Turning off current (maximum) Isolation voltage Maximum power consumption

1794-IB8 8 (sinking type) 24V DC 8 mA 1.5 mA 50V DC (850V DC test for 60s) 3.5 W

1794-IB16 16 (sinking type) 24V DC 8 mA 1.5 mA 50V DC (707V DC test for 60s) 6.1 W

1794-IB32 32 (sinking type) 24V DC 4.1 mA 1.5 mA 50V DC (2121V DC test for 2s) 6.0 W

1794-IB32K 32 (sinking type) 24V DC 4.1 mA 1.5 mA 50V DC (2121V DC test for 2s) 6.0 W

(2) Environmental and mechanical specifications

Environmental parameters: working humidity of 5% -95% (no condensation), storage temperature of -40~+85 ℃, vibration (working) of 5 g @ 10-500 Hz (IEC 60068-2-6), impact (working) of 30 g (IEC 60068-2-27);

Mechanical parameters: Module size (with base) 94 × 94 × 69 mm (3.7 × 3.7 × 2.7 inches), weight 71-79 g, no shell (open type), relying on external shell protection.

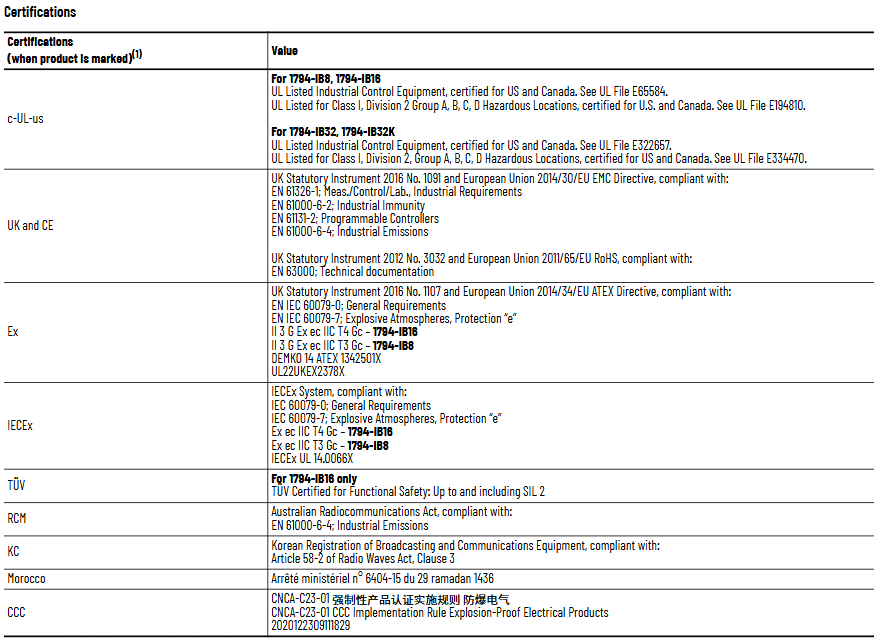

(3) Compliance certification

The module has passed multiple international certifications to ensure compliant use worldwide, with core certifications including:

Safety certification: UL (Industrial Control Equipment, Class I Division 2 Hazardous Areas, USA/Canada), CSA, TUV (IB16 supports SIL 2 functional safety);

Electromagnetic compatibility (EMC): EN 61326-1, IEC 61000-6-2/4, in compliance with anti-interference and radiation requirements for industrial environments;

Dangerous Place Certification: ATEX (European Zone 2), IECEx (International Zone 2), UKEX (UK Zone 2);

Environmental certification: Compliant with the EU RoHS Directive (2011/65/EU) and China CCC Explosion proof Certification (CNCA-C23-01).

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor

- SHINKAWA

- Other Brands