Bentley Baker Hughes 2300 Series Vibration Monitors

Bentley Baker Hughes 2300 Series Vibration Monitors

Description

The 2300 Vibration Monitors are designed for using on a broad range of machine trains or individual casings where the sensor point count fits the monitor’s channel count and where advanced signal processing is desired.

Monitor Key Features

2300/25

Technical specifications and performance parameters

(1) Core parameters for vibration monitoring

Specific specifications for parameter categories

Measurement range velocity: 0-20 mm/s (RMS, RMS); Displacement: 0-200 μ m (peak to peak, PP); Axial position (Thrust): 0-500 μ m (peak to peak) supports users to customize the range according to device types (such as low-speed motors, high-speed turbines), meeting the vibration characteristics requirements of different devices

Frequency response 5-1000 Hz (standard range); Optional 1-1000 Hz (low-frequency extension) covers the vibration frequency range of the vast majority of industrial rotating equipment (such as motor frequency vibration, bearing fault high-frequency vibration), ensuring the integrity of monitoring data

Accuracy level ± 2% of full scale (at 25 ℃ ambient temperature); ± 3% full range (0-60 ℃ working temperature range) high measurement accuracy ensures the accuracy of abnormal vibration identification, avoiding false alarms or missed alarms

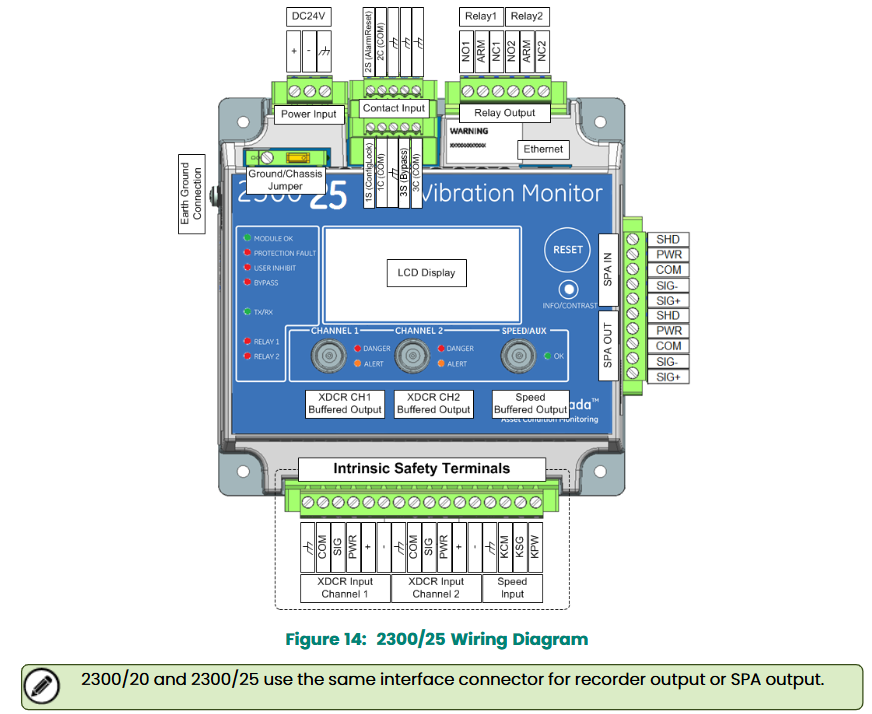

Input signal type compatible with ICP ® Type accelerometer (with built-in charge amplifier, requiring 24V DC excitation); Or piezoelectric acceleration sensors (requiring external charge amplifiers) support mainstream industrial vibration sensors, reducing the compatibility cost of upgrading or replacing user devices

(2) Electrical and Environmental Specifications

Power requirements: 18-30V DC (standard), or 85-265V AC (optional AC power supply module), power consumption ≤ 5W (no alarm state), with overvoltage and overcurrent protection functions, suitable for unstable power supply environments in industrial sites.

Output signal:

Analog output: 4-20mA isolated output (independent for each channel), load resistance 0-500 Ω, can be directly connected to DCS, PLC or SCADA system for remote data monitoring.

Switching output: 2 sets of SPDT (single pole double throw) relay outputs (1 set per channel/monitoring dimension), rated load 250V AC/5A or 30V DC/5A, used for local alarm (such as sound and light alarm lights) or equipment shutdown control.

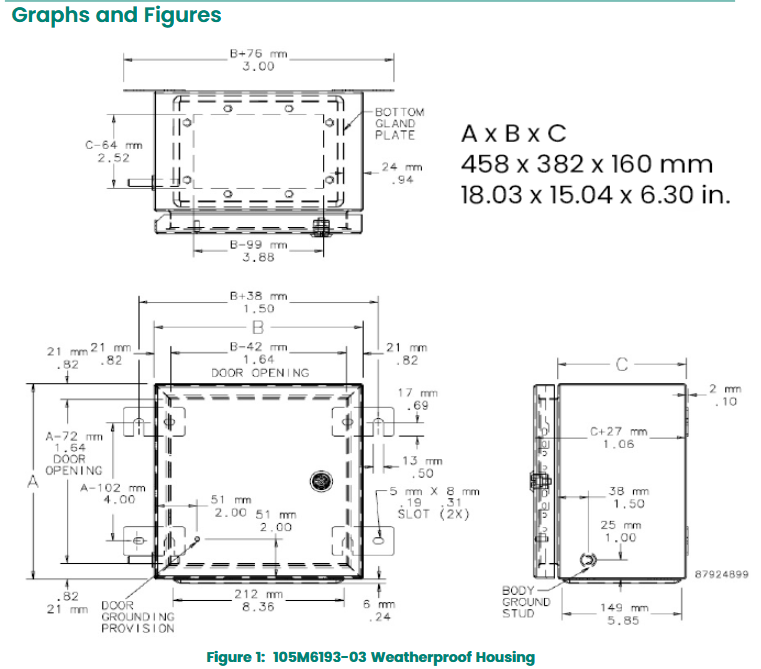

Environmental adaptability: working temperature -20-60 ℃, storage temperature -40-85 ℃, relative humidity 0-95% (no condensation), protection level IP65 (panel installation part), can withstand harsh conditions such as dust, humidity, and vibration in industrial sites.

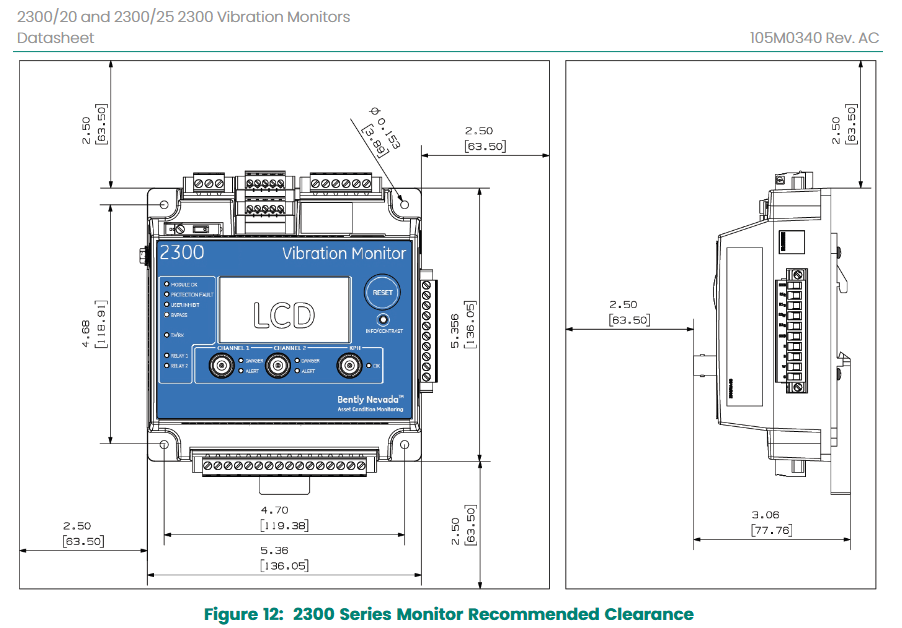

Installation method: Panel embedded installation (standard 1/4 DIN size, i.e. 96 × 48mm panel opening), installation depth ≤ 150mm, suitable for compact layout inside control cabinets.

Core functions and operational design

(1) Monitoring and protection functions

Multi level alarm setting: Supports 2-level alarm thresholds ("Warning", "Danger"), users can configure specific values through panel buttons or software (such as speed warning value of 10 mm/s, danger value of 15 mm/s), alarm status triggers external response through relay output, and panel LED lights (red=danger, yellow=warning, green=normal) intuitively display device status.

Vibration trend recording: Some models have built-in data storage function, which can record the maximum and average vibration trend in the past 30 days (sampling interval can be set between 1-60 minutes). It supports exporting data through RS485 communication (Modbus RTU protocol) for equipment fault tracing and life prediction analysis.

Fault diagnosis assistance: Some high terminal models (such as 2303-D) support vibration frequency spectrum analysis (with specialized software), which can identify common fault characteristic frequencies (such as bearing inner ring fault frequency, unbalanced vibration frequency), helping operation and maintenance personnel locate the root cause of the fault (such as "imbalance", "misalignment", "bearing wear").

(2) Operation and Configuration

Local operation: The panel is equipped with 4 tact buttons (menu, confirm, increase/decrease), paired with a 2-line 16 character LCD display screen, which can directly set parameters such as range, alarm threshold, sampling interval, etc. without the need for external tools, making it convenient for on-site debugging.

Remote configuration: Supports connecting to upper computers (such as computers and HMIs) through RS485 communication interface (Modbus RTU protocol), using Baker Hughes dedicated configuration software (such as "VibroLink") for parameter settings, data reading, and trend analysis, suitable for centralized management of batch devices.

Hardware Design and Accessories

(1) Hardware structure characteristics

Isolation design: Optoelectronic isolation (isolation voltage 2500V AC, 1 minute) is used between input signals, analog output, and power supply to effectively suppress electromagnetic interference (EMI) in industrial sites, ensure stable monitoring data, and avoid misoperation caused by external interference.

Redundancy protection: The relay output has a "Fail Safe" mode, which can be set to "alarm when power is off" or "normal when power is off" to prevent the device from losing protection due to monitor power failure; Some models support sensor open/short circuit detection. When the sensor fails, it immediately triggers a "sensor failure" alarm, prompting operation and maintenance personnel to troubleshoot.

(2) Supporting accessories

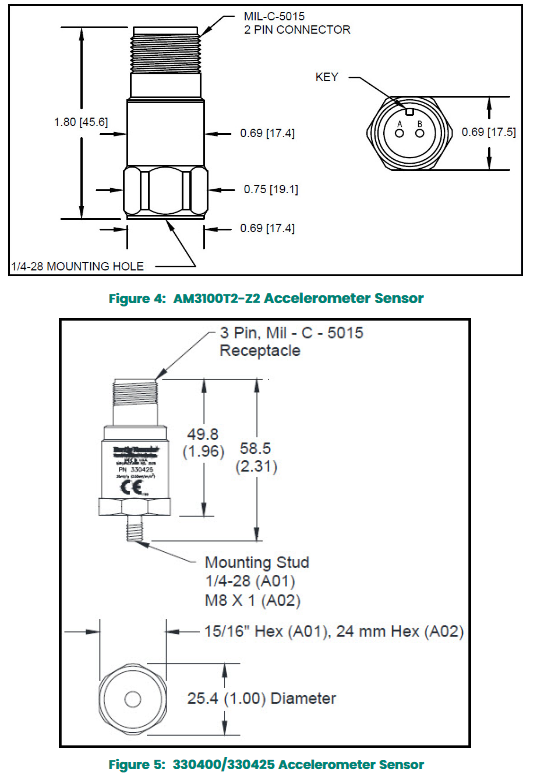

Sensor: Recommended to be paired with Baker Hughes 3300 series ICP ® Acceleration sensors (such as 330103 radial sensors and 330180 axial sensors) provide a complete solution of "monitor+sensor" to ensure signal matching and stability.

Communication and connection accessories: Provide RS485 communication cables (model 2300-CAB), sensor extension cables (model 3300-CAB), and panel mounting brackets (model 2300-MNT) to simplify on-site installation and wiring.

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor

- SHINKAWA

- Other Brands