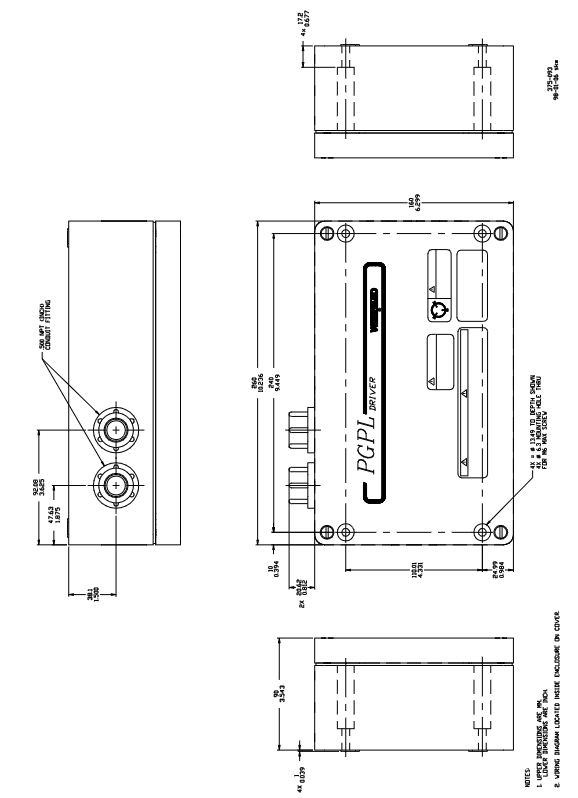

Woodward PGPL electro-hydraulic actuator/driver(37519 G version)

Alternative value: Used to replace traditional hydraulic mechanical governors such as PG-PL, PGD, PGL, etc., retaining the convenience of the original PG type transmission and connecting rod system, while possessing high precision and flexibility of electronic control.

Connecting rod adjustment: Using 2/3 of the output stroke to achieve "no load full load" adjustment, the remaining stroke is distributed to both ends (ensuring that fuel can be cut off when turned off and maximum fuel can be provided at full load).

(2) Oil selection and maintenance

Oil requirements: viscosity 100-300SUS (at operating temperature), compatible with nitrile, polyacrylic acid, fluorocarbon sealing materials; Recommend using automotive/gas engine oil (such as SAE 10W30, 15W40) to avoid pollution;

Oil change cycle: Under normal working conditions, it should be replaced every year. In harsh environments (high temperature, high pollution), the cycle needs to be shortened; When changing the oil, it is necessary to drain it while it is hot, rinse it with a clean solvent (such as kerosene), and then add new oil.

(3) Electrical installation

Caution in hazardous areas: Do not plug or unplug connectors when live, and replacement parts must meet the requirements of Class I, Zone 2;

Grounding: Drivers and actuators need to be separately grounded to avoid parallel wiring with high voltage/high current wires and reduce EMI interference.

2. Initial operation and troubleshooting

(1) Initial operation steps

Confirm that the oil level is normal, there is no leakage, and the connecting rod is connected correctly;

Set the "low-speed start" mode on the electronic governor and prepare emergency shutdown measures;

Start the prime mover and gradually adjust the governor to the rated speed to ensure that the actuator operates linearly and without any jamming;

Verify closed-loop control: Change the control signal and check if the actuator output matches the feedback signal (10 ± 5mA corresponds to the minimum position, 175 ± 10mA corresponds to the maximum position).

(2) Common faults and solutions

Possible causes of symptoms and solutions

Unable to start/fuel rack does not open, actuator has no electrical signal, oil pump steering error, low oil level, connecting rod stuck. Check power and control signals; Confirm the direction of oil pump rotation; Oil replenishment; Repair the connecting rod

Slow action/delayed response, low speed (<200rpm), improper oil viscosity (too thin/too thick), worn oil pump, increasing speed or installing a boost servo; Replace the compatible oil; Repair/replace oil pump

Calibrate the connecting rod again due to the fluctuation of the prime mover (traveling/surging), nonlinearity of the connecting rod, oil contamination/foaming, and inaccurate parameters of the electronic governor; Change the oil; Adjust the parameters of the speed controller

Overheating of the actuator, high ambient temperature, driving speed exceeding 1500rpm, and installation of an oil cooler for oil oxidation; Reduce the rotational speed; Replace antioxidant oil

Principles of System Control and Safety Design

1. Control logic (closed-loop feedback)

Signal input: The electronic governor outputs a 0-200mA control signal to the driver based on the speed/load requirements;

Signal conversion: The driver converts the control signal into a 0-200mA driving current and sends it to the torque motor of the actuator;

Mechanical action: The torque motor drives the pilot valve, controls the flow of high-pressure oil to the power cylinder, and drives the output shaft action (adjusts the fuel/steam valve);

Feedback loop: The position sensor of the actuator converts the actual position into a 3.6-4.4Vdc voltage signal and feeds it back to the driver; The driver compares the control signal with the feedback signal, adjusts the output current until they match, and achieves precise positioning.

2. Security protection design

Power loss protection: When the control voltage is lost, the torque motor has no magnetic force, the spring pushes the pilot valve to release oil, and the power cylinder resets to the "minimum fuel" position to prevent the prime mover from overspeeding;

Overspeed independent protection: It is explicitly required that the prime mover be equipped with an overspeed shutdown device independent of the PGPL system (not dependent on the MPU of the actuator) to avoid loss of control caused by actuator failure;

Dangerous area protection: The shell is sealed and the wiring meets explosion-proof standards to prevent sparks from igniting dangerous gases.

Product Support and Services

1. Service Options

Quick replacement/exchange: Provide replacement parts of the same model within 24 hours to reduce downtime;

Fixed cost maintenance/renovation: Clearly define the maintenance cost in advance and restore it to a "near new product" state after maintenance;

Spare parts ordering: The model and serial number (indicated on the nameplate) of the actuator/driver must be provided to ensure that the spare parts match.

2. Compliance and Document Reference

Certification: UL (Class I, Zone 2), compliant with EU Machinery Directive 98/37/EC (without CE marking);

Related manuals: 25071 (hydraulic oil selection), 36692 (power cylinder specifications), 36693 (base specifications), 50532 (EMI control).

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor

- SHINKAWA

- Other Brands