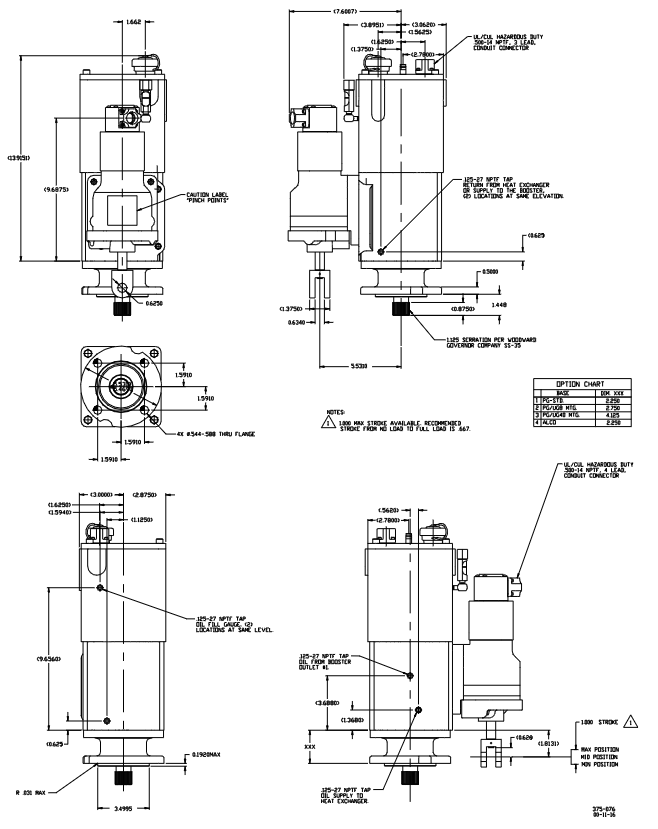

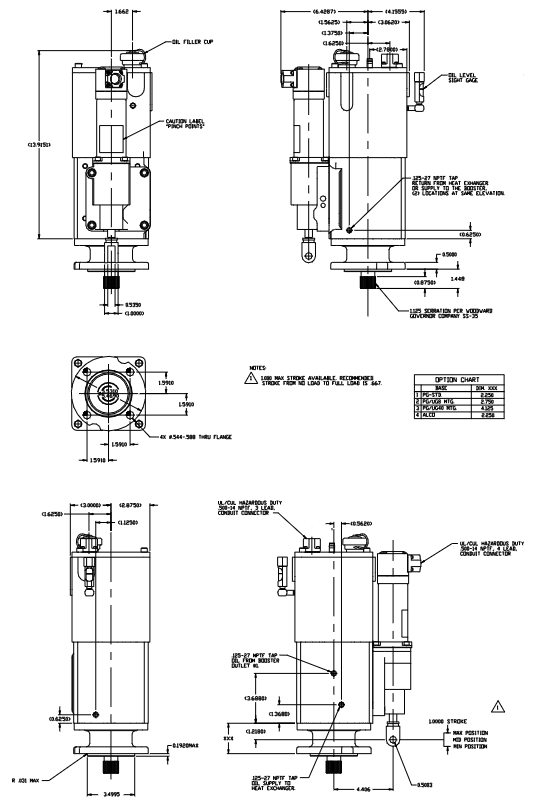

Woodward PGPL electro-hydraulic actuator/driver(37519 G version)

Alternative value: Used to replace traditional hydraulic mechanical governors such as PG-PL, PGD, PGL, etc., retaining the convenience of the original PG type transmission and connecting rod system, while possessing high precision and flexibility of electronic control.

Woodward PGPL electro-hydraulic actuator/driver(37519 G version)

Product core positioning and application scenarios

1. Core positioning

Technology type: Electro hydraulic integrated actuator, including proportional drive interface, capable of receiving electronic controllers (such as Woodward 2301A series, 700 series, etc.) Peak ® The 0-200mA position signal output by the 150 and 505 controllers is controlled by a torque motor and a follow-up pilot valve to drive the output shaft, and coupled with a contactless position sensor to achieve closed-loop control.

Alternative value: Used to replace traditional hydraulic mechanical governors such as PG-PL, PGD, PGL, etc., retaining the convenience of the original PG type transmission and connecting rod system, while possessing high precision and flexibility of electronic control.

2. Scope of application

Adaptation equipment: gas engines, steam turbines (such as power generation turbines, industrial compressor driven turbines);

Hazardous Area Compliance: Compliant with UL certification, suitable for Class I Zone 2, A/B/C/D hazardous environments (models with magnetic electric sensor (MPU) options do not have UL/cUL certification);

Linkage system: It needs to be used in conjunction with an electronic governor, and its core function is to convert electronic control signals into mechanical actions, adjust fuel supply or steam valve opening, and achieve speed/load control.

Core components and technical specifications of the product

The PGPL system consists of two parts: the "actuator" and the "driver". The former is responsible for mechanical action output, while the latter realizes electrical signal conversion and closed-loop control. The specific parameters are as follows:

1. Actor: the core of mechanical action

(1) Core configuration and performance

Description of Key Parameters for Categories

Linear output of power cylinder: 16J (12ft lb), 23J (17ft lb), 39J (29ft lb), 79J (58ft lb)

Rotation output: 16N · m (12lb ft), 23N · m (17lb ft), 39N · m (29lb ft), 79N · m (58lb ft) linear stroke 25mm (1 inch), rotation stroke 30 °; Available travel/output is 2/3 of the maximum value

Hydraulic system oil pump: PG spur gear pump (low-speed version 0.812 inches thick, ≤ 1000rpm); High speed version 0.562 inches thick,>1000rpm)

Working pressure: Standard 896kPa (130psi), 58ft lb model 1655kPa (240psi) with built-in oil tank (2.5L/2.6 quarts), requires separate oil selection (refer to manual 25071)

Drive required speed: 200-1000rpm (bidirectional rotation, with check valve); Maximum 1500rpm (unidirectional, with plug)

Power: Maximum 375W (0.5hp), oil cooler needs to be selected for high speed or high ambient temperature

Position feedback non-contact Hall effect sensor outputs 3.6-4.4Vdc feedback voltage to the driver, achieving closed-loop control

Environmental adaptability working temperature: -29~+104 ℃ (-20~+220 ℉, limited by oil temperature)

Vibration resistance: Complies with WGC RV2 standard, maximum 7G parallel direction of drive shaft. Shell material: base/column made of cast iron, feedback shell made of aluminum alloy, internal parts made of surface hardened steel

(2) Optional Features

Oil cooler: It needs to be installed when the actuator temperature exceeds 93 ℃ (200 ℉), and is divided into internal and external types;

Booster servo motor: using starting air to provide instant oil pressure, assisting equipment to start quickly;

Magnetic electric sensor (MPU): 1-2 optional, detects the speed of the prime mover through the drive shaft of the governor (cannot be used as a component of the overspeed protection system).

2. Driver: Electrical signal conversion core

(1) Core configuration and performance

Description of Key Parameters for Categories

Electrical signal input/output input: 18-32Vdc power supply, 0-200mA control signal (from electronic speed controller)

Output: 0-200mA drive signal (to actuator torque motor), 4-20mA position feedback signal (to indicator), built-in 210mA current limit to protect torque motor

The closed-loop control receives the 3.6-4.4Vdc signal from the actuator position sensor. After comparing the control signal, the output is adjusted and calibrated before leaving the factory. No field adjustment is required

Installation and environmental enclosure: cast aluminum box (cannot be directly installed on the prime mover)

Working temperature: -40~+70 ℃ (-40~+158 ℉)

Wiring: Use temperature resistant wires with a temperature rating of ≥ 90 ℃, comply with Class I, Zone 2 wiring standards, and require grounding to avoid electromagnetic interference (EMI). Refer to manual 50532

Wire length limit 16AWG (1.5mm ²): battery driver 457m, driver actuator 457m

14AWG (2.5mm ²): Battery driver 610m, driver actuator 610m shielded wire requires twisted pair, one end grounded and the other end suspended

Key requirements for installation and operation and maintenance

1. Installation specifications

(1) Mechanical installation

Attitude: The actuator should be installed vertically or nearly vertically to avoid force on the drive shaft (the actuator should not be placed on the drive shaft);

Transmission connection: The drive shaft should engage freely without any jamming, side load, or excessive axial clearance. The installation bolts should be evenly tightened to avoid shaking;

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor

- SHINKAWA

- Other Brands