How to order AMS 6500 Classic system protection card?

AMS 6500 Classic System Protection Card

System Overview

The AMS 6500 Classic system is a system developed by Emerson for the protection and condition monitoring of rotating machinery. It includes multiple protection cards and can achieve comprehensive monitoring and protection of key rotating machinery such as steam turbines, gas turbines, compressors, and water turbines. It complies with international standards such as API 670 and is PlantWeb ® A part of the digital factory architecture that can be integrated with Ovation ® And DeltaV ™ Process control system integration provides machinery health status information and diagnostic tools for operators and maintenance personnel.

Introduction to Main Protection Cards

A6740/A6740-10 16 channel output relay module

Purpose: To build a complete API 670 mechanical protection monitor in conjunction with AMS 6500, which can take clear, alarm, or danger signals from any channel as input and output them from output relays through Boolean logic and time delay.

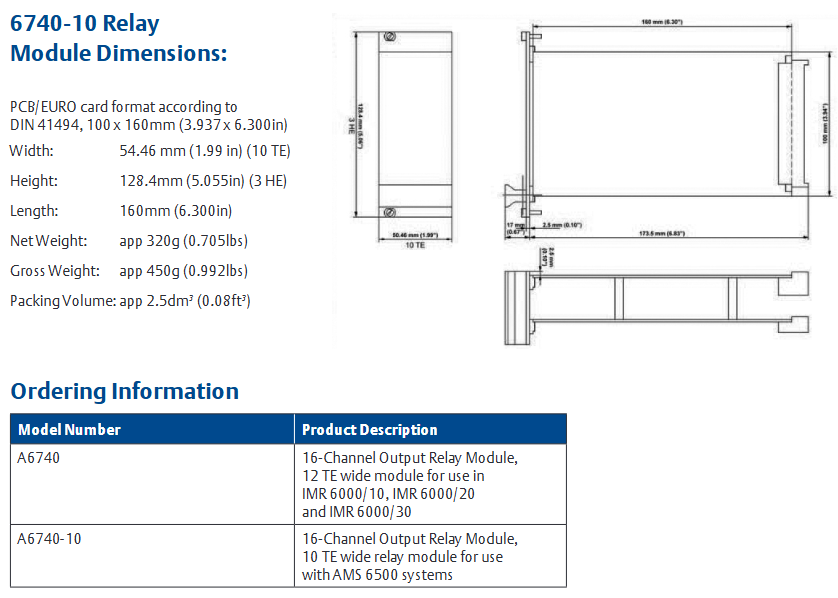

Features: 3U size, 2-slot plug-in module, compliant with API 670 standard, hot swappable; A6740 is 12TE wide and suitable for IMR6000 series racks, while A6740-10 is 10TE wide and suitable for IMR6500 series racks; It has 60 inputs, 30 logical expressions, and 16 relay outputs.

Technical parameters: The relay is a redundant and configurable mechanical relay, with a control voltage of 13-32 VDC and a contact load of 48V, 1A. It can be selected as normally open/normally closed, normally powered on/off, and single pole double throw (SPDT); Logic supports multiple types and can define up to 30 logical expressions; Time delay of 0-30 seconds.

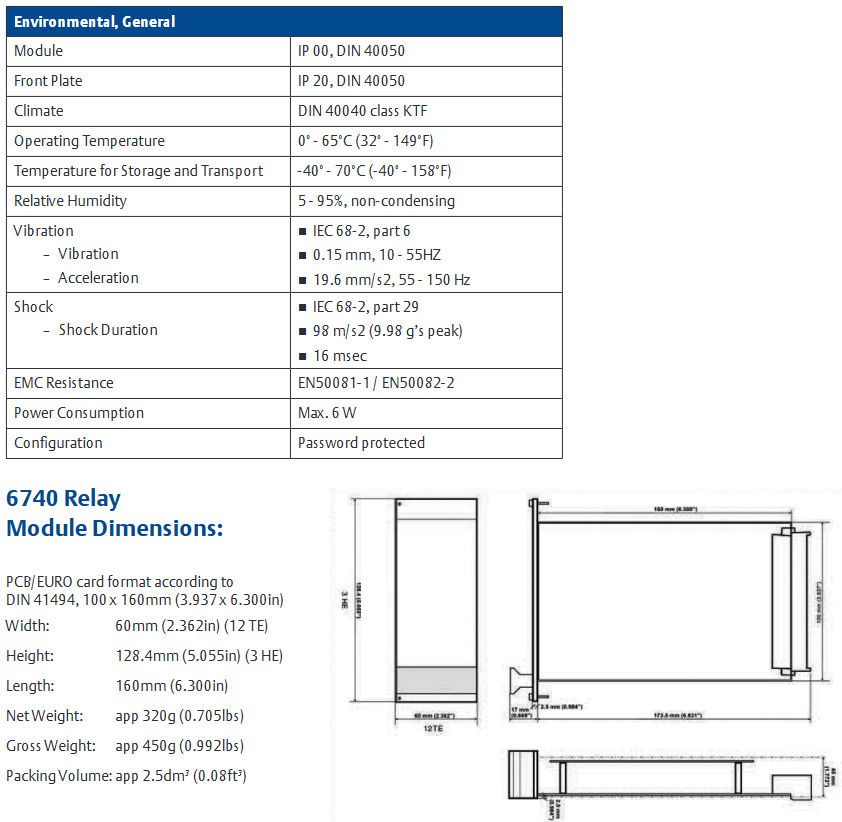

Environment and dimensions: working temperature of 0 ° -65 ° C, storage and transportation temperature of -40 ° -70 ° C, relative humidity of 5-95% (non condensing); A6740 is 60mm wide (12TE), A6740-10 is 54.46mm wide (10TE), 128.4mm high, and 160mm long.

A6125 shell piezoelectric vibration monitor

Purpose: Used to monitor the vibration of the casing from acceleration sensors, drive alarms and relays by comparing vibration parameters with alarm settings, and protect machinery.

Features: Dual channel, 3U size, 1-slot plug-in module, compliant with API 670 standard, hot swappable; Support remote selection of limit multiples and trip bypasses; There is buffering and proportional output before and after.

Technical parameters: Two independent differential inputs, input type is piezoelectric (accelerometer or speedometer), input resistance>100 k Ω, input voltage range -5 to+15 VDC; The frequency range varies depending on the type and configuration of the sensor; The sensor is powered by a constant current of 2-8mA and 30 VDC.

Environment and dimensions: working temperature 0 ° -65 ° C, storage temperature -30 ° -85 ° C, relative humidity 5-95% (non condensing); Width 30.0mm (6TE), height 128.4mm, length 160.0mm.

A6120 Shell Seismic Vibration Monitor

Purpose: Used in conjunction with electric seismic sensors to monitor the seismic vibration of the casing, and achieve mechanical protection by comparing vibration parameters with alarm settings.

Features: Dual channel, 3U size, 1-slot plug-in module, compliant with API 670 standard, hot swappable; Support remote selection of limit multiples and trip bypasses; There is buffering and proportional output before and after.

Technical parameters: Two independent channels, input type is electric (electromechanical), input resistance>100 k Ω, input voltage range -5-+15 VDC; Adjustable frequency range; Increase coil current by 0-8mA, configurable, with an accuracy of ± 0.5%.

Environment and size: Same as A6125.

A6824/A6824-R ModBus and Rack Interface Module

Purpose: Read the parameters of all AMS 6500 modules, output through ModBus TCP/IP and/or ModBus RTU (serial), and build a complete API 670 mechanical protection monitor.

Features: 3U size, 1-slot plug-in module, compliant with API 670 standard, hot swappable; Password protected user configuration; A6824 is 6TE wide with no redundancy options, while A6824-R is 4TE wide with optional redundancy.

Technical parameters: ModBus RTU (serial) baud rate 19.2 kbaud, data bit 8, parity bit, stop bit 1; ModBus Ethernet has RJ45 sockets and 10BaseT; Default IP address 192.168.255.1, subnet mask 255.255.255.0.

Environment and dimensions: working temperature 0 ° -65 ° C, storage temperature -30 ° -85 ° C, relative humidity 5-95% (non condensing); A6824 is 30mm wide (6TE), A6824-R is 25mm wide (4TE), 128.4mm high, and 160mm long.

Other protection cards

A6620 Process Input Monitor: Four channel, monitoring process inputs such as temperature, pressure, load, etc. The input type is voltage or current, with alarm output and multiple output modes.

A6140 Shaft Absolute Vibration Monitor: Dual channel, combined with relative displacement sensor and chassis mounted vibration sensor, monitors shaft absolute vibration.

A6220 axis eccentricity monitor: dual channel, monitoring axis eccentricity through displacement sensors, suitable for large sliding bearing machinery.

A6110 axis relative vibration monitor: dual channel, monitoring axis relative vibration, suitable for sliding bearing machinery.

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor

- SHINKAWA

- Other Brands