Emerson Machine Monitoring Systems RPM Transformer PR 9376

The structure is sturdy, with a frequency range of 20kHz and a mechanical resolution (modulus 1) of 1.5mm. The output pulse voltage is high, and the pulse rise/fall time is only 1 µ s. The output has short-circuit protection function, and the working temperature range is -30...+100 ° C.

Emerson Machine Monitoring Systems RPM Transformer PR 9376

Basic characteristics and applications

PR 9376 is an RPM sensor used for non-contact measurement of the rotational frequency of ferromagnetic mechanical components, with the following features:

The structure is sturdy, with a frequency range of 20kHz and a mechanical resolution (modulus 1) of 1.5mm. The output pulse voltage is high, and the pulse rise/fall time is only 1 µ s. The output has short-circuit protection function, and the working temperature range is -30...+100 ° C.

Widely applicable in industrial and laboratory scenarios, it can be used in conjunction with electronic evaluation equipment such as epro RMS 700 or MMS 6000 speed monitoring systems to complete measurement, monitoring, monitoring or control tasks such as rotation direction detection, slip, gear ratio, backlash, etc. It can also be used to issue proximity signals, alarms, switch control, count mechanical events, etc. Due to its high resolution, fast response internal electronic components, and sharp output pulse edges, it can measure extremely high and low speeds with high precision.

Working principle and structure

Working principle: The sensor head is a differential sensor composed of two series connected magnetic sensitive semiconductor resistors, installed above a small permanent magnet. The two resistors in the electronic part of the sensor form a Wheatstone bridge, which controls the subsequent DC switching amplifier with fast push-pull short-circuit protection output. When the trigger mark made of soft iron or steel approaches the sensor vertically, it interferes with the internal magnetic field, causing the bridge to become unbalanced and the output voltage to switch to a high level; When the trigger marker passes by, the bridge becomes unbalanced in reverse and the output signal returns to a low level. The output pulse has sharp edges and can be capacitively coupled with subsequent electronic devices even at the lowest triggering frequency.

Construction: High quality electronic circuits are packaged in a sturdy stainless steel casing, and the connecting cables are insulated with polytetrafluoroethylene. If necessary, flexible metal tubes can be added for protection.

Technical parameters

Measurement related

Measurement principle: Differential magnetic field sensor.

Trigger method: Non contact triggering through mechanical triggering of markers, with the trigger marker material being soft iron or steel.

Trigger frequency range: 20kHz.

Allowable gap: For St 37 material, it is 1.5mm.

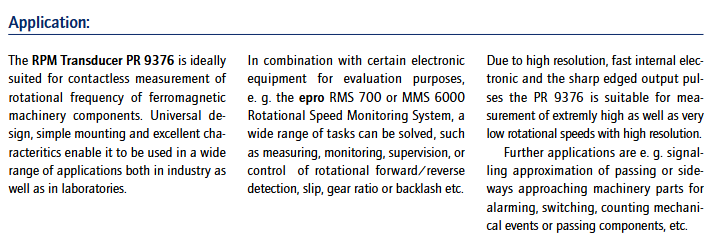

Trigger marking size limit: standard module 1 gear (involute profile, St 37 material); Special trigger wheels need to refer to the chart.

output parameters

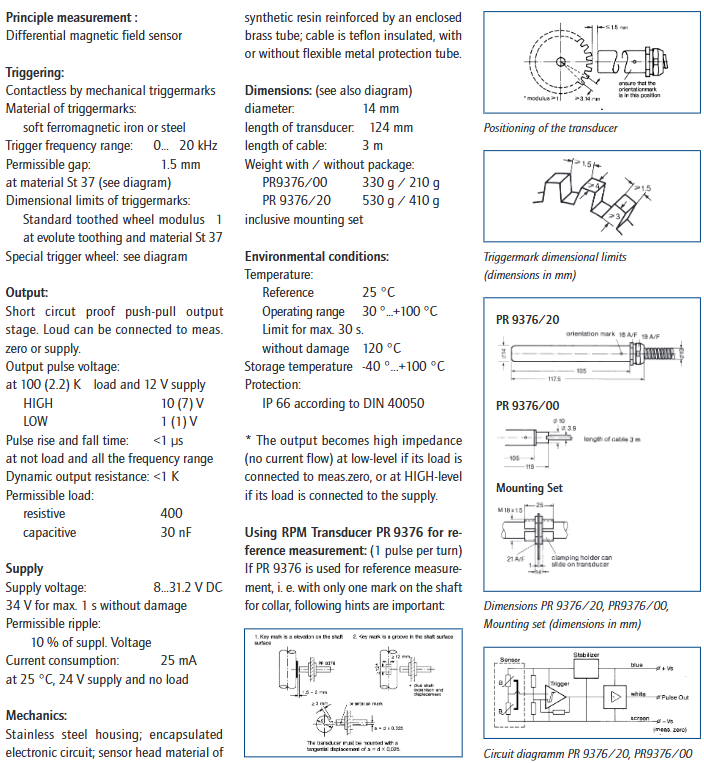

Output type: Short circuit protection push-pull output stage, load can be connected to measurement zero or power supply.

Output pulse voltage: Under a load of 100 (2.2) K and a 12V power supply, the high level is 10 (7) V and the low level is 1 (1) V.

Pulse rise and fall time:<1 μ s (no load and within all frequency ranges).

Dynamic output resistance:<1K.

Allowable load: resistive load 400 Ω, capacitive load 30nF.

Power parameters

Power supply voltage: 8... 31.2V DC, can withstand up to 1 second without damage at 34V.

Allow ripple: 10% of the power supply voltage.

Current consumption: 25mA at 25 ° C, 24V power supply, and no load.

Mechanical and environmental parameters

Mechanical structure: stainless steel shell, encapsulated electronic circuit, sensor head material made of synthetic resin (reinforced with closed brass tube), cable insulated with polytetrafluoroethylene (optional flexible metal tube protection).

Dimensions: Diameter 14mm, sensor length 124mm, cable length 3m.

Weight: PR9376/00 with/without packaging is 330g/210g; PR 9376/20 with/without packaging is 530g/410g (both including installation kit).

Environmental conditions: reference temperature 25 ° C; operating temperature -30...+100 ° C; maximum withstand temperature (within 30 seconds, without damage) 120 ° C; storage temperature -40...+100 ° C; protection level IP 66 (compliant with DIN 40050 standard).

Other information

Reference measurement precautions: If used for reference measurement (with only one mark or collar on the shaft), relevant instructions must be followed to ensure normal operation in harsh industrial environments, a flat sensor surface, and oil and water resistant installation through standard cable sealing sleeves.

Order number: PR 9376/00 (without metal cable protection) is 9408-093 76001; PR 9376/20 (with metal cable protection) is 9408-093 76201.

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor

- SHINKAWA

- Other Brands