KOLLMORGEN AKD ® Servo drive fault card

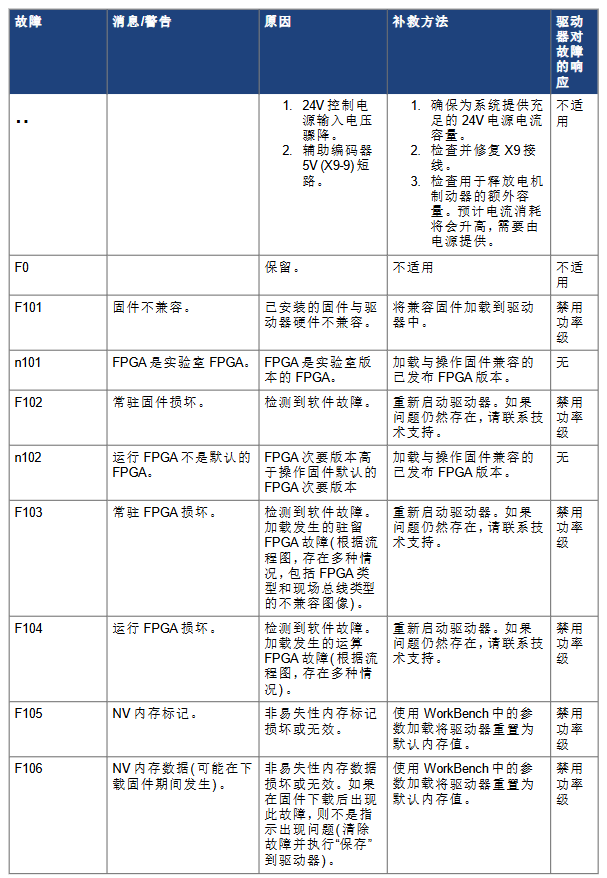

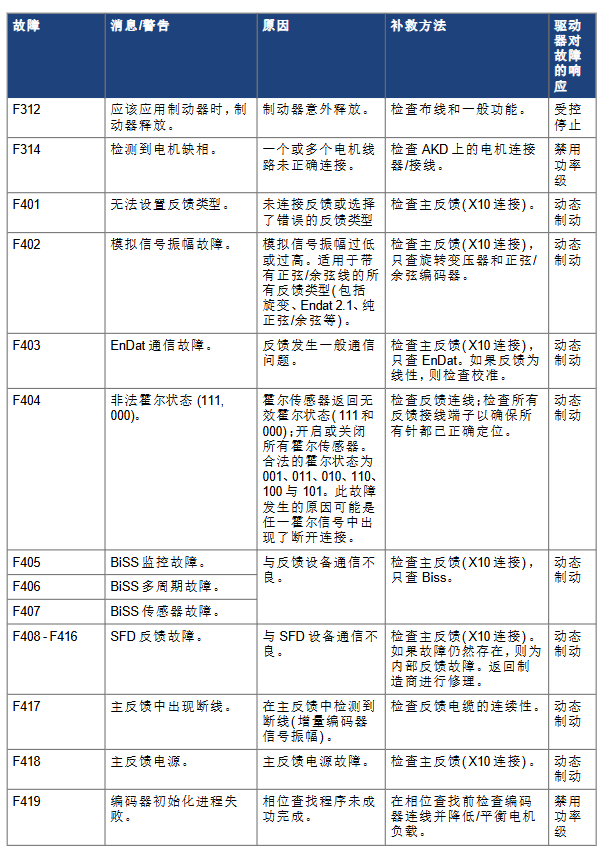

F404 (Illegal Hall State): The Hall sensor returns 111/000 (the legal state is 001/010/011/100/101), check if the Hall wiring is broken or has poor contact, and trigger dynamic braking protection.

F438/n438 (position following error): The actual position exceeds the maximum allowable deviation. Check if the load has increased, if the feedback commutation setting is correct, and adjust the servo gain or position deviation threshold.

F470 (Feedback 3 Fault): The third level feedback (X9 interface) is not connected or communication is abnormal. Check FB3.FAULTRA for detailed information, repair the wiring or replace the feedback device.

(3) Power supply and power level faults (F500-F599)

1. Bus voltage related

F501/n501 (Bus Overvoltage): The bus voltage exceeds the threshold, often due to high regenerative energy of the load. It is necessary to reduce the load, optimize the deceleration curve, or increase the regenerative resistance capacity.

F502 (bus undervoltage): If the bus voltage is below the threshold, check if the input power supply is stable, check if the power supply wiring is loose or if there is a power supply fault, and trigger a controlled shutdown.

F503 (Bus capacitor overload): Connect the three-phase driver to a single-phase input or ultra single-phase load, confirm the power phase wiring (L1/L2/L3), and replace the matching power supply.

2. Power level and regeneration faults

F519 (short circuit in regeneration circuit): The regeneration resistor or IGBT is short circuited. It is necessary to disconnect the power supply and check the resistance wiring. Contact technical support to replace the power components.

F521/n521 (regeneration circuit over power): The power of the regeneration resistor is insufficient. Replace it with a larger capacity resistor or enable DC bus sharing, and disable power level protection equipment.

F525 (output overcurrent): If the current exceeds the peak value of the driver, check if the motor is short circuited and if there is a feedback fault. Urgently disable the power level to prevent hardware damage.

F531 (power level fault): Power level hardware fault, restart is ineffective and the driver needs to be replaced, which is a fatal fault.

(4) Fieldbus and communication failure (F600-F799)

F602 (Safety Torque Off, STO): Trigger the STO function, confirm safety conditions, and then power on again, in accordance with functional safety specifications (such as EN ISO 13849).

F702/n702 (fieldbus communication disconnected): All fieldbus communication is lost. Check the X11 interface wiring (such as EtherCAT, CANopen), host settings, and trigger controlled shutdown.

F706/n706 (fieldbus set point loss): The host stops sending set points due to timeout. Check the stability of the bus connection, reduce the bus load, or adjust the timeout parameter.

(5) AKD-T exclusive fault (F800-F999)

AKD-T supports running BASIC programs, and many faults are related to program execution. The typical code is as follows:

F801 (divided by zero): There is a division by zero operation in the program, modify the code to avoid invalid calculations.

F802 (Stack Overflow): Insufficient program stack memory, optimize code structure, reduce nested calls.

F824/F825 (mode incompatible): DRV.OPMODE needs to be set to 2 (position mode), DRV.CMDSOURCE needs to be set to 5 (program command), adjust the parameters and restart the program.

F901 (Too Many Cams): The number of cams defined in the program exceeds the upper limit, reduce cam configuration or optimize motion logic.

Key fault troubleshooting process

Identification code: Obtain the fault code through panel display or WorkBench, confirm the code type (F/n) and priority.

Identify the cause: Based on the corresponding entries on the fault card, investigate the hardware wiring (such as feedback, power supply, motor phase lines), parameter configuration (such as feedback type, current limit), and environmental conditions (temperature, ventilation).

Execute remedial measures:

Wiring faults (such as F314 motor phase loss, F404 Hall wire breakage): Repair the wiring after power failure, and confirm the correctness of the connection before re enabling.

Parameter faults (such as F105 NV memory error, F501 bus overvoltage): Reset parameters or adjust thresholds through WorkBench, save and restart the drive.

Hardware failures (such as F201 RAM damage, F531 power level failure): If restarting is ineffective, please contact technical support and return to the factory for repair if necessary.

Clear the fault: Use the DRV.CLRFAULTS command or WorkBench button to clear the fault, confirm that the fault is eliminated, and then re enable the drive.

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor

- SHINKAWA

- Other Brands