SERVOSTAR ® CD series servo amplifier

SERVOSTAR ® CD series servo amplifier

Basic Information

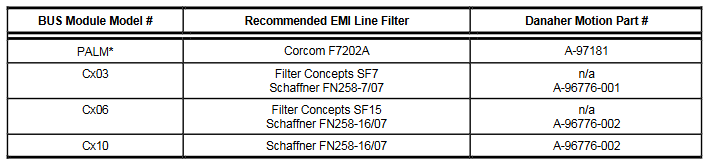

Product positioning: SERVOSTAR ® The CD series is an industrial grade servo amplifier launched by Danaher Motion, covering three models: Cx03 (3A continuous), Cx06 (6A continuous), and Cx10 (10A continuous), suitable for high-precision motor control scenarios. It has passed UL/cUL 508C certification (US and Canadian markets) and CE certification (EU market), and needs to be integrated into industrial equipment for use.

Core support: The document comes with a CD-ROM, which includes a technical manual (in PDF format), MOTIONLINK debugging software, and Adobe Acrobat Reader installation program; Hardware needs to be equipped with motors, feedback devices (encoders/rotary transformers), optional regenerative resistors (ERH-26), and EMI filters (such as Corcom F7202A, Schaffner FN258 series).

Version Description: The document version is M-SS-017-07 Rev C. The Series 5 (Version 2) model is not compatible with the PA-LM bus module, and some features (such as extended I/O interface C9) are only supported by Series 5; The firmware needs to be version 4.0.0 or higher (UCB1V2 label model), and it must be paired with a compatible version of IGNITE upgrade tool.

Safety and compliance requirements

(1) Personnel qualifications and operating standards

Qualification requirements: Only professionals with experience in motor installation and commissioning are allowed to operate, and they must be familiar with standards such as IEC 364/CENELEC HD 384, DIN VDE 0100, and national safety regulations.

Core Warning:

Risk of electric shock: During equipment operation, there is a 230VAC input and a 430VDC bus voltage. After power failure, there is residual dangerous voltage in the capacitor. It is necessary to wait for at least 10 minutes and measure the voltage (<50V) before operation; Reliable grounding is necessary (low impedance grounding, otherwise personal safety cannot be guaranteed).

Electrostatic protection: Contains electrostatic sensitive components. Before operation, it is necessary to release human static electricity and avoid contact with high insulation materials (such as chemical fibers and plastic films). The equipment should be placed on a conductive surface.

High temperature and mechanical risks: During operation, the temperature of the heat sink can reach 80 ℃ (176 ° F) to avoid burns; The start-up process may cause the motor to rotate, and it is necessary to ensure that there are no personnel/obstacles in the hazardous area.

(2) Compliance standards

Key standards applicable to certification/instruction scope

UL/cUL 508C specifies design requirements for power filtering, grounding, insulation, etc. to prevent fires, electric shock, and personal injury in the US and Canadian markets

CE certification EU market EMC directive (89/336/EEC): compliant with EN 55011 (radiated/conducted emissions), EN 61000-4 series (immunity); Low Voltage Directive (73/23/EEC): Complies with EN 50178, EN 60204

Global mechanical safety requires equipment to comply with EN 60204 (Mechanical Electrical Equipment) and EN 292 (Mechanical Safety), and equipment manufacturers need to complete risk assessments

Installation and wiring

(1) Mechanical installation

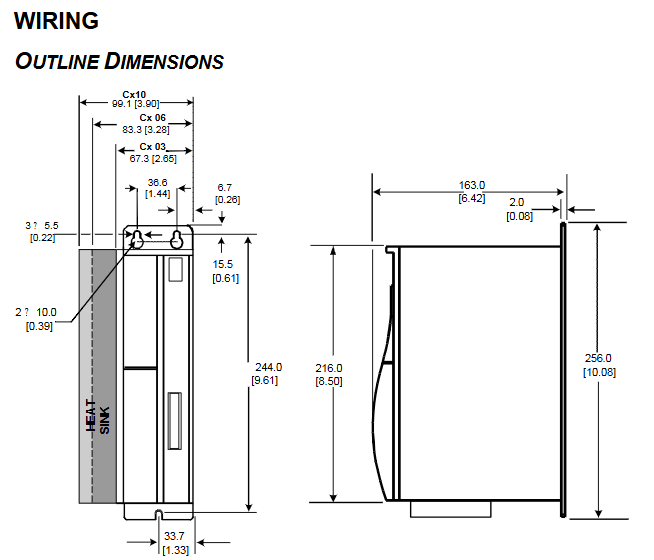

Installation requirements: Vertically fixed to the conductive grounding backplate (metal contact ensures EMC performance), with reserved heat dissipation space around (left-right spacing ≥ 12.7mm, up-down spacing ≥ 63.5mm); Secure with M4 (or 10-32) screws, torque 20 lb in (2.26 Nm).

Dimensions and Weight: Cx03 measures 67.3 × 163 × 244mm (width × height × depth) and weighs 1.61kg; Cx06 measures 83.3 × 163 × 244mm and weighs 2.22kg; Cx10 measures 99.1 × 163 × 256mm and weighs 2.69kg.

(2) Electrical wiring

Grounding and bonding:

Safe grounding: All components (amplifiers, filters, motors) need to be connected to a "star shaped grounding point". It is recommended to use copper bars or flat braided wires (to reduce high-frequency impedance) to avoid relying on a single wire (inductance 8nH/inch, which affects the filtering effect).

Shielding bonding: The shielding layer of the motor line and feedback line should be exposed near the amplifier and connected to the backplane through metal clamps (such as Phoenix Contact products); If metal conduits are not used for power supply incoming lines, shielded cables must be used and reliably bonded.

Key interface wiring:

Power input: 115/230VAC (± 10%), single/three-phase optional (Cx0x200 only single-phase), wire diameter 14-12AWG (2.5-4mm ²), external fuse required (10AT for Cx03, 15AT for Cx06, 22-27AT for Cx10).

Motor and Feedback: The length of the motor wire (14AWG/2.5mm ²) is recommended to be ≤ 25m. The feedback wire (encoder/rotary transformer) needs to be shielded with twisted pair. The C2 interface (feedback) pin corresponds to different functions of the resolver/encoder/sine encoder (such as the resolver sine signal connected to Pin1-2, and the encoder A/B phase connected to Pin1-2/4-5).

The control I/O: C3 interface includes ± 10V differential analog input (Pin2-3), 24V remote enable (Pin7-8), fault relay output (Pin5-6, 1A/24VDC) and analog output (Pin13, monitoring speed/current, ± 10V/12 bit resolution), wire diameter 18-22AWG (0.3-0.75mm ²), and it is recommended to use cold pressed terminals.

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor

- SHINKAWA

- Other Brands