Rockwell Automation AutoMax™ Distributed Power System

AutoMax ™ Distributed Power Systems: Redefining Industrial Drive Control Architecture

In the field of modern industrial automation, the requirements for the performance, flexibility, and reliability of drive systems are becoming increasingly stringent. The traditional centralized control architecture often faces bottlenecks when dealing with complex, multi axis, and high dynamic response applications. Rockwell Automation launches AutoMax ™ Distributed Power System (DPS) represents an innovative solution that significantly improves overall system efficiency by deploying control tasks and power conversion processing in a distributed manner. This article aims to provide a comprehensive technical perspective for engineers and application experts by delving into the core architecture, key components, software ecosystem, and technological advantages of DPS.

Overview and Core Concepts of Distributed Power Systems (DPS)

AutoMax ™ DPS is not a single product, but a complete system architecture designed specifically for AC/DC motor drive control. Its core concept lies in "decoupling control hierarchy" and "distributed intelligence". The system assigns high-level control algorithms, drive outer loop control, and real-time control of power modules to different dedicated processors, thereby achieving more optimized task division and faster response speed.

This distributed architecture brings significant advantages in multiple aspects:

Improved performance: By using modular components and high-performance RISC microprocessors, processing power can be dispersed and enhanced.

Enhance flexibility: AC and DC drivers can be mixed and controlled within the same system, allowing customization of the most suitable power technology according to the requirements of each stage of the process.

Simplified engineering and debugging: The universal software interface makes different power technologies transparent to users, and graphical configuration tools simplify the installation and debugging process.

Reduce overall cost: Modular design facilitates maintenance and upgrades, and power hardware can be installed away from the control cabinet and closer to the motor, significantly reducing on-site wiring costs and space requirements.

The hardware foundation of DPS is built on the powerful AutoMax platform, which consists of an AutoMax processor located inside the control cabinet (responsible for high-level coordination and logic), a universal drive controller module (responsible for drive level closed-loop control), and power module interfaces and modules installed near the motor (responsible for actual power conversion). The components are connected through noise resistant fiber optic links, with a communication distance of up to 750 meters, ensuring signal integrity and precise synchronization during long-distance transmission.

DPS Core Hardware Architecture Analysis

The hardware architecture of DPS is the foundation for implementing distributed control, mainly composed of general components and specialized components for different driver types.

1. General hardware components

Universal Drive Controller Module: The UDC module is one of the brains of DPS, installed as a high-speed slave processor module in the AutoMax rack. It is based on RISC technology and has built-in non-volatile flash memory for storing its own and PMI operating system, driver configuration parameters, and UDC tasks (one for each driver). The front panel provides two fiber optic communication channels for transmitting and receiving ports and four programmable D/A output ports for connecting recorders or instruments. The LED indicator lights on the panel visually display the communication link and drive status.

Fiber optic link: This is the neural network that connects the UDC module with the remote PMI. Manchester code is adopted to carry out point-to-point serial communication at the rate of 10Mbps. Fiber optic cables are completely unaffected by electromagnetic interference and can effectively prevent ground loop problems, ensuring reliable data transmission in harsh industrial environments.

2. DC drive hardware components

For the SD3000/SF3000 series DC drive, its PMI is a four slot rack that includes:

Power module: Provides power to all modules inside the PMI rack.

PMI processor module: Based on RISC, it executes inner loop control algorithms, manages communication within the rack, and provides feedback and diagnostic information to the UDC module.

Rotary Transformer and Drive I/O Module: Processing external rotary signals (with a resolution of 12/14 bits) and providing analog input and drive I/O interfaces. Its rotary to digital converter can automatically match the characteristics of cables up to 150 meters in length.

DC power supply technology module: Digitally processes all armature and excitation signals from the DC power module for current and magnetic field regulation algorithms.

The DC power module provides a complete range from 1 to 1000 horsepower (higher power can be achieved through parallel connection), including irreversible and reversible versions, providing continuous and adjustable voltage and current for DC motors.

3. Communication driven hardware components

According to the power level, the hardware configuration of AC drivers can be divided into several main types:

SA500 driver: suitable for lower power (14-48 amperes). Its characteristic is compact structure, and the DC bus power supply can supply power to up to six AC power modules. The PMI function is integrated into the regulator board inside the power module, achieving high integration.

SA3000 medium power drive: suitable for the range of 70-240 amperes. Adopting a four slot PMI rack similar to DC drive, but the rightmost slot is equipped with an AC power technology module. The power module adopts advanced IGBT technology and pulse width modulation technology, with built-in comprehensive diagnostic functions.

SA3000 high-power drive: suitable for high current applications ranging from 534-1457 amperes. Adopting an eight slot PMI rack, parallel interface modules and up to three gate drive interface modules have been added to support parallel operation of multiple power units. The local power interface module is responsible for conditioning and isolating feedback signals from the power unit.

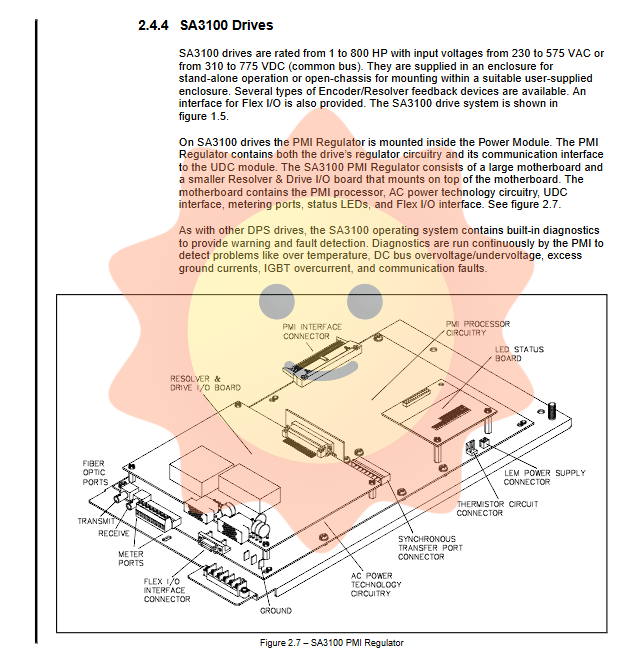

SA3100 drive: covering the range of 1 to 800 horsepower. Its uniqueness lies in the fact that the PMI regulator, as a replaceable modular circuit board component, is directly installed inside the power module, integrating the processor, power technology circuit, UDC interface, and Flex I/O interface, resulting in a more compact structure.

1567 Power Max ™ Drive: Targeting medium voltage applications (1500-5500 horsepower). This is a complex system that includes independent rectifier cabinets, inverter cabinets, PMI subsystems, AutoMax racks, and liquid cooling systems. Its inverter adopts a three-level topology structure based on GTO and neutral point clamping. The PMI subsystem includes an eight slot rack, power interface board, etc., designed specifically for high-voltage and high-power environments.

Software and Programming: AutoMax Programming Execution Environment

All DPS drivers share a unified software interface - AutoMax programming execution software, which is a graphical configuration and programming tool running in the Microsoft Windows environment. It makes complex drive parameter configuration intuitive, and engineers only need to fill in the corresponding parameters in the graphical form based on the nameplate data of the motor, power module, transformer, and feedback equipment to complete the basic configuration.

This software provides a complete offline programming application suite:

System configurator: used to define the hierarchical structure of systems, regions, and racks.

Rack Configurator: Used for virtual configuration of AutoMax racks, including inserting modules, setting networks, and configuring driver parameters.

Variable configurator: used to map variable names to I/O points or public memory addresses.

Task Manager: Used to create user applications, also known as "tasks".

DPS applications are developed in the AutoMax environment and support three types of tasks:

BASIC task: Run on the AutoMax processor for high-level control.

Control Block Task: Can run on AutoMax processors or UDC modules. The tasks used for UDC modules (known as UDC tasks) use a predefined set of control blocks specifically responsible for driving the outer loop control.

Ladder diagram logic task: runs on the AutoMax processor and is suitable for sequential logic control.

Each AutoMax rack supports up to 32 tasks, shared by processors and UDC modules. Among them, UDC tasks are the core of driver control, and each UDC module can run two independent tasks, each controlling a driver. These tasks exchange data with the AutoMax processor through dual port memory, achieving a perfect combination of high-level coordination and low-level control.

UDC/PMI Communication and System Operation

The interaction between UDC module and PMI is the key to real-time control of DPS. After power on connection, PMI will actively request and load its operating system from the UDC module. Afterwards, both parties establish a synchronized instruction feedback message loop:

Instruction message: At the end of each UDC task scanning cycle, it is sent by the UDC module to PMI. Contains instruction data, track data, and predefined variable values that undergo changes.

Feedback message: Sent by PMI to the UDC module before the start of each UDC task scanning cycle. Contains feedback data and track data that has changed since the last message.

This tight, high-speed fiber based synchronous communication mechanism ensures high bandwidth and low latency of the control loop. The PMI operating system independently executes selected adjustment algorithms (such as vector control, V/Hz control, etc.) and continuously runs diagnostic programs to monitor temperature, DC bus voltage, ground current, IGBT overcurrent, and communication faults, achieving deep state monitoring and fault protection.

System Integration and Engineering Documentation

The deployment of DPS is accompanied by a complete set of standard engineering documents, namely the 'instruction manual'. This set of documents is provided after the equipment is shipped and serves as the cornerstone for equipment delivery records and subsequent maintenance. It typically includes:

Bill of Materials: List all components.

Dimensional drawings, wiring diagrams, and schematics: provide detailed information on mechanical and electrical installations.

Flowchart and Interconnection Diagram: Display the relationships and wiring of various parts of the system.

Panel layout diagram and operation station diagram: indicate the physical layout of the equipment.

Program documentation: Record control logic.

Index table: Ensure the integrity and up-to-date status of the drawing set.

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor

- SHINKAWA

- Other Brands