ABB Symphony Plus S+Control BRC410 Controller

-As a 'client': collecting data from intelligent electronic devices (IEDs, such as meters and sensors);

-As a 'server': pushing control data to third-party PLCs (such as AC 800M, AC 500) or SCADA systems;

-Bidirectional mode: enables real-time data exchange and control command issuance with wireless HART transmitters

Redundancy and Reliability Redundancy supports communication link fault tolerance under configuration, and is paired with industrial grade Ethernet devices (such as fiber optic switches) to achieve long-distance (fiber optic link) and high reliability communication. It is suitable for cross plant and strong interference scenarios (such as power plant boiler areas and water pump stations), ensuring uninterrupted communication

Seamless system upgrade and compatibility

BRC410 is the core carrier of ABB's "development without elimination" policy, and its compatibility and upgrade capabilities are designed to fully protect users' existing investments, specifically reflected in:

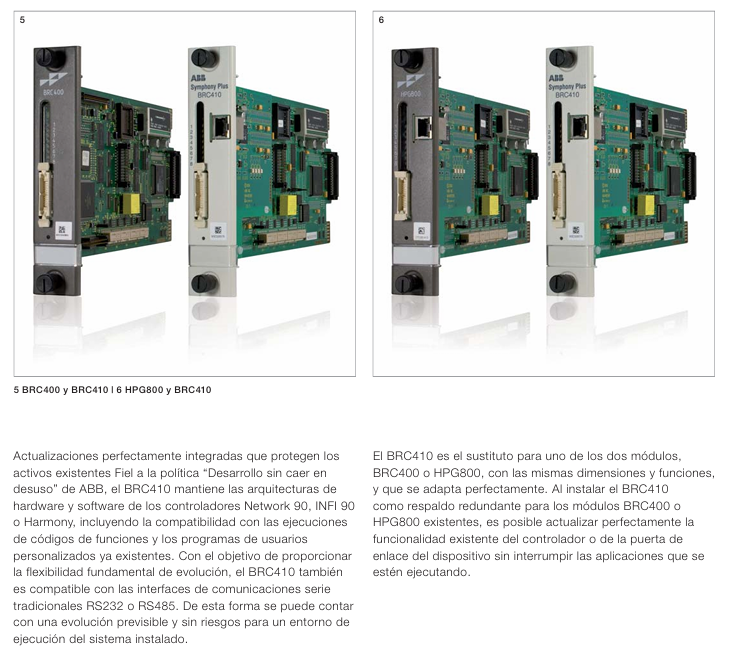

Hardware and functional compatibility

Consistent in size and functional interoperability with previous generation controllers (BRC400, HPG800), one module can be directly replaced as a redundant backup without the need to modify cabinet layout or wiring;

Compatible with user-defined programs and functional block execution logic of old systems such as Network 90 and INFI 90, it can be migrated to BRC410 without rewriting code.

Online upgrade capability

When BRC410 is used as a redundant backup module for BRC400 or HPG800, it can gradually upgrade controller functions (such as upgrading from "basic control" to "Modbus TCP integration") or gateway capabilities without interrupting existing production applications, achieving "zero downtime upgrade";

Supports the coexistence of traditional RS232/RS485 serial port interfaces and new generation Ethernet interfaces. Users can transition to high-speed Ethernet communication in stages according to their needs, avoiding one-time system replacement costs.

Typical application scenarios

BRC410, with its characteristics of "high reliability, strong compatibility, and multi scenario adaptation", is core applied in the following fields:

Power industry: Unit control of thermal power plants and hydropower plants (such as boiler water level control, turbine speed regulation), control of auxiliary systems (pumps, fans), and exchange of power grid dispatch data;

Water industry: urban waterworks (dosing, filtration process control), sewage treatment plants (aeration, sedimentation process control), supporting data integration with remote pumping station's IED equipment;

Other key industries: continuous production process control in chemical, metallurgical and other fields, compatible with third-party equipment (such as flow meters, valve positioners), achieving full process automation.

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor

- SHINKAWA