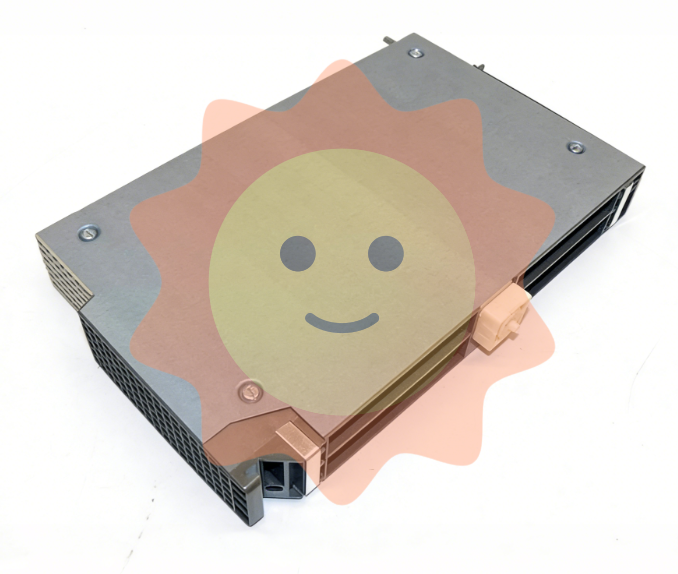

SIEMENS 6ES5491-0LB11: SIMATIC S5 Adapter Casing

Functional Overview and System Integration

The SIEMENS 6ES5491-0LB11 is an essential mechanical and electrical adapter component within the SIMATIC S5 automation system. Specifically designed for the S5-115U series, this adapter casing serves as the primary mounting interface for specialized sub-modules that do not natively match the standard rack dimensions. It provides the necessary physical support and electrical continuity required to bridge the internal system bus to auxiliary functional components.

In the modular world of S5 automation, flexibility is achieved through precise mechanical engineering. The 6ES5491-0LB11 ensures that expansion modules remain securely fastened even in environments prone to industrial vibrations. By utilizing this adapter, engineers can maximize the utility of their existing subracks, allowing for a higher density of control logic and specialized interfacing without the need for complete hardware redesigns.

Technical Specifications

The engineering profile of the 6ES5491-0LB11 is defined by its compatibility with the SIMATIC S5 backplane bus and its adherence to industrial safety standards. The following parameters represent the core specifications for this module:

Specification Category Technical DetailsProduct Family SIMATIC S5-115U

Article Number 6ES5491-0LB11

Module Type Adapter Casing / Housing

Mounting Compatibility S5 Subracks / Rails

Weight Approximately 0.45 kg

Material Industrial Grade Polymer and Metallic Shielding

Bus Interface S5 Backplane Connector

Protection Rating IP20 (According to IEC 60529)

Key Features and Advantages

1. Precision Bus Alignment

The 6ES5491-0LB11 is designed with precision-molded guides that ensure perfect alignment between the sub-module and the backplane connector. This eliminates the risk of pin damage during installation and guarantees consistent electrical contact for high-speed data transmission within the S5 bus architecture.

2. Electromagnetic Shielding

Industrial control cabinets are often saturated with electromagnetic interference (EMI). The 6ES5491-0LB11 features internal metallic shielding properties that help isolate the encased sub-module from external noise. This is critical for maintaining the signal-to-noise ratio required for accurate analog-to-digital conversions and high-speed pulse processing.

3. Durable Mechanical Design

Constructed from high-impact industrial polymers, the casing is built to withstand the thermal and mechanical stresses of 24/7 industrial operations. It features integrated locking mechanisms that provide visual and tactile confirmation of secure module seating, preventing accidental disconnects during machine operation.

Engineering Note: Installation Requirements

When installing the 6ES5491-0LB11, ensure the subrack power is disconnected. The adapter must be seated firmly into the slot before the sub-module is inserted into the casing. Proper grounding of the S5 rail is mandatory to ensure the shielding properties of the casing are effective.

Installation and Maintenance Protocols

To ensure the longevity of the SIEMENS 6ES5491-0LB11 and the modules it houses, the following maintenance and installation standards should be followed:

Mounting: Use the standard S5 locking screw to secure the casing to the subrack rail.

Thermal Management: Verify that the adapter does not obstruct the natural convection flow within the rack, especially when high-power output modules are located in adjacent slots.

Connector Inspection: Periodically inspect the backplane pins for oxidation if the module is used in corrosive or high-humidity environments.

ESD Precautions: Standard Electrostatic Discharge (ESD) protocols must be followed when handling the casing and the internal sub-modules to prevent damage to sensitive CMOS logic.

Industrial Application Scenarios

The 6ES5491-0LB11 is utilized across several heavy industrial sectors where the SIMATIC S5 system remains a cornerstone of automation:

Manufacturing & Production

In automotive assembly lines where specialized pulse-width modulation (PWM) modules or high-speed counters require adapter casings to interface with the main S5-115U controller.

Process Industry

Within chemical plants and refineries where legacy sensors and specialized signal conditioning modules are integrated into modern control loops through adapter interfaces.

Power Distribution

Used in electrical substations for housing communication adapters that bridge S5 protocols to modernized SCADA interfaces.

Reliability and Lifecycle

As part of the Siemens legacy support system, the 6ES5491-0LB11 is recognized for its exceptional Mean Time Between Failures (MTBF). Its passive design means there are no active electronic components to wear out, ensuring that the mechanical interface remains reliable for decades. It complies with VDE 0160 and various industrial EMC directives, ensuring it can operate safely alongside modern high-voltage industrial equipment.