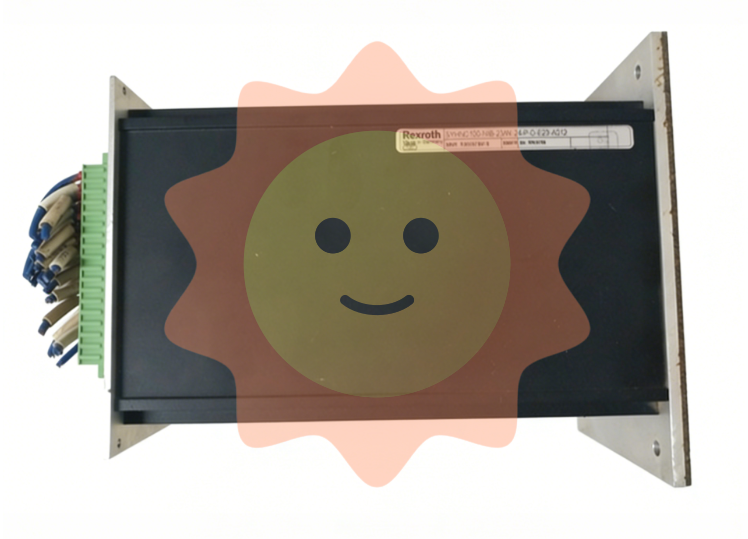

REXRTOH SYHNC100-NIB-23/W-24-P-D-E23-A012 Synchronous Motor: Precision in Motion

The REXRTOH SYHNC100-NIB-23/W-24-P-D-E23-A012 stands as a high-caliber component within the realm of precision motion control. As a member of the SYHNC series of synchronous motors, it is engineered to deliver exceptional performance where accuracy, reliability, and controlled movement are paramount. This brushless, permanent magnet synchronous motor is designed to operate in conjunction with a compatible drive or controller, translating electrical signals into precise mechanical motion. Its design philosophy centers on providing stable torque, excellent speed regulation, and seamless integration into automated systems ranging from intricate laboratory equipment to robust industrial machinery.

Core Technology and Operating Principle

This motor operates on the principle of a rotating magnetic field. The stator, equipped with windings, is energized by a controlled 24V DC supply via an external drive. This creates a magnetic field that rotates in sync with the frequency of the supplied power. The rotor contains permanent magnets that lock into this rotating field, causing the shaft to turn at a synchronous speed directly proportional to the input frequency. The "NIB" and encoder-related codes in the model number typically indicate the integration of a feedback device, such as an incremental encoder or resolver. This device provides real-time data on shaft position and speed to the controller, enabling closed-loop control for precise positioning and velocity accuracy that is unattainable with open-loop stepper systems.

Defining Characteristics

The SYHNC100 model is defined by its specific mechanical and electrical interface. The suffix "23/W-24-P-D-E23-A012" details its configuration: a 24V DC nominal voltage, specific winding type (P), a designated feedback system (D), and a precise mechanical interface or shaft type (E23-A012). This makes it a plug-and-play solution for systems designed around this specific electromechanical standard.

Key Features and Performance Advantages

High Torque Density: Generates significant torque relative to its frame size (SYHNC100), making it powerful yet compact for space-constrained applications.

Precise Speed Holding: Maintains a constant speed independent of load variations within its rated capacity, essential for synchronous conveyor systems or spindle drives.

Smooth Low-Speed Operation: Provides stable and smooth rotation even at very low speeds, eliminating the cogging effect often associated with other motor types.

Integrated High-Resolution Feedback: The built-in encoder allows for precise angular positioning, enabling its use in sophisticated servo applications.

High Dynamic Response: Excellent acceleration and deceleration capabilities due to low rotor inertia, allowing for rapid start-stop cycles.

Durability and Low Maintenance: The brushless design eliminates mechanical commutator wear, leading to a long operational lifespan and reduced maintenance needs.

Efficient Performance: High electrical-to-mechanical conversion efficiency, reducing heat generation and energy consumption over long duty cycles.

Technical Specifications

Parameter SpecificationManufacturer Model REXRTOH SYHNC100-NIB-23/W-24-P-D-E23-A012

Motor Type Permanent Magnet Synchronous Motor (PMSM)

Nominal Supply Voltage 24 V DC

Feedback System Integrated Encoder (Incremental, type indicated by 'D')

Frame Size SYHNC100 (indicating physical dimensions and power class)

Commutation Electronic, brushless

Control Requirement Requires an external synchronous servo drive/amplifier

Primary Application Precision positioning, speed control, and servo applications

Industry Applications

The REXRTOH SYHNC100 motor is deployed across a diverse range of industries that demand precise motion. In automation, it drives pick-and-place units, CNC tool changers, and precision linear actuators. Within the packaging industry, it controls the cut-to-length film sealing jaws and rotary filling stations. It is found in medical devices such as automated analyzers and imaging equipment positioning stages. For printing and textile machinery, it ensures precise register control and tension management. Its combination of precision and reliability also makes it suitable for scientific instrumentation, semiconductor handling equipment, and robotic joints where smooth, accurate movement is critical.

System Integration and Drive Compatibility

Successful implementation of this synchronous motor requires pairing it with a matched drive controller capable of synchronous motor commutation. The drive provides the precisely timed, three-phase power to the motor windings based on commands from a host PLC or motion controller and feedback from the motor's encoder. The integration involves connecting the motor's power leads, encoder cable, and possibly a brake wire to the drive. Parameters such as motor pole count, encoder resolution, current limits, and tuning gains must be correctly configured in the drive software to optimize performance, prevent instability, and ensure protection against overloads. Proper mounting and alignment are also crucial to prevent bearing stress and ensure optimal performance.

Conclusion

The REXRTOH SYHNC100-NIB-23/W-24-P-D-E23-A012 synchronous motor exemplifies the integration of robust engineering and precision control. It offers a reliable, high-performance solution for applications where traditional motors fall short in accuracy, smoothness, or dynamic response. By delivering consistent torque, exact speed control, and precise positional feedback, it serves as a fundamental building block in advanced mechatronic systems. For designers and engineers seeking a dependable motion solution for demanding automated tasks, this motor provides the technological foundation necessary to achieve superior performance, efficiency, and control accuracy.

- User name Member Level Quantity Specification Purchase Date

- Satisfaction :

-