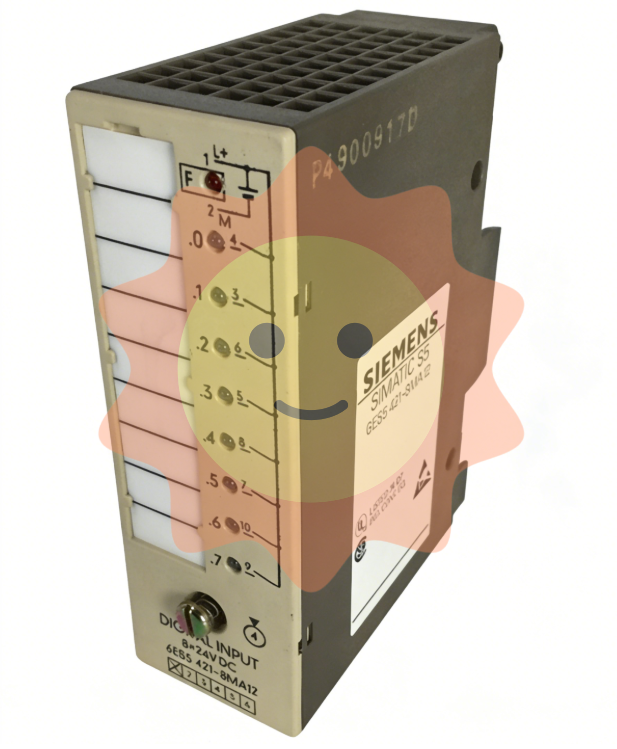

SIEMENS 6ES5421-8MA12: SIMATIC S5 Digital Input Logic

Functional Role in Process Automation

The SIEMENS 6ES5421-8MA12 is a fundamental building block in the Distributed Control System (DCS) and PLC architectures of the SIMATIC S5 series. Specifically designed for digital signal acquisition, this module serves as the primary gateway for binary data entering the control logic. In industrial environments, the module interprets the state of various field devices—converting mechanical or electronic switching states into digital "1" or "0" signals that the S5 CPU can process.

This module is part of the S5-115U/100U range, known for its modularity and high-density wiring. The 6ES5421-8MA12 allows for the monitoring of discrete process variables, ensuring that automation sequences are triggered accurately based on real-time field conditions. Its internal circuitry is optimized to filter out mechanical contact bounce and electrical transients, providing a clean data image to the system backplane.

Detailed Technical Specifications

The engineering profile of the 6ES5421-8MA12 is defined by its electrical robustness and compatibility with standard 24V DC industrial power systems. The data below reflects the technical parameters outlined in the original Siemens hardware manuals:

Technical Feature Specification DetailProduct Family SIMATIC S5-115U / S5-100U

Article Number 6ES5421-8MA12

Input Channels 8 / 16 / 32 Channels (Module Dependent)

Rated Input Voltage 24 V DC

Signal Delay Typically 3.0 ms to 0.2 ms

Input Current (at "1" signal) Approx. 8 mA

Isolation Galvanic Isolation via Optocouplers

Current Consumption Low power internal bus draw

Key Features and Advantages

1. Galvanic Isolation for System Safety

The 6ES5421-8MA12 incorporates optocouplers between the field-side terminals and the internal PLC bus. This galvanic isolation is vital for protecting the expensive central processing unit from high-voltage surges or ground loops that may occur at the sensor level. It ensures that an electrical fault in the field does not lead to a catastrophic system-wide failure.

2. Robust Signal Conditioning

Industrial signals are often plagued by electromagnetic interference (EMI). This module features integrated input filters that suppress noise and contact chatter. This ensures that only valid state changes are reported to the controller, preventing "ghost" triggers in safety-critical sequences.

3. Modular High-Density Design

As part of the compact S5 subrack system, the module utilizes a standardized front connector that allows for rapid wiring and module replacement. The compact footprint enables high I/O density within small control cabinets, making it ideal for retrofitting older machinery where space is a premium.

Installation and Wiring Guidelines

Installation Tip: To ensure long-term stability, it is recommended to use shielded cables for input lines exceeding 100 meters, especially when routed near high-power variable frequency drives (VFDs).

When installing the 6ES5421-8MA12, the module is inserted into the designated slot on the SIMATIC S5 bus rail. The electrical connection to the backplane is made automatically upon insertion. For field wiring, the front-side screw or spring-loaded terminals should be utilized. It is essential to ensure that the 24V DC supply is polar-correctly connected to the power pins to prevent logic errors.

Mounting: Use the standard S5 locking mechanism to secure the module in the subrack.

Grounding: Ensure the subrack's grounding rail is connected to the plant ground to maximize EMI suppression.

Addressing: Set the module address via the S5 hardware configuration or jumpers as required by the specific CPU version in use.

Industrial Application Scenarios

The SIEMENS 6ES5421-8MA12 is currently deployed across a wide range of industrial applications:

Manufacturing and Assembly

Used to monitor the position of robotic arms and the status of safety light curtains in automated automotive assembly plants.

Water Treatment Plants

Tracking the open/close status of hydraulic valves and monitoring level switches in large-scale filtration systems.

Food and Beverage Industry

Facilitating high-speed counting on bottling lines and monitoring proximity sensors on packaging machinery where wash-down resistance and reliability are mandatory.

Reliability and Lifecycle

Despite being part of a legacy system, the 6ES5421-8MA12 continues to be a cornerstone of industrial reliability. Siemens’ commitment to high-quality components ensures a Mean Time Between Failures (MTBF) that spans decades. For maintenance, it is recommended to periodically inspect the front connectors for oxidation and verify the LED status indicators, which provide immediate visual confirmation of the input signal states.