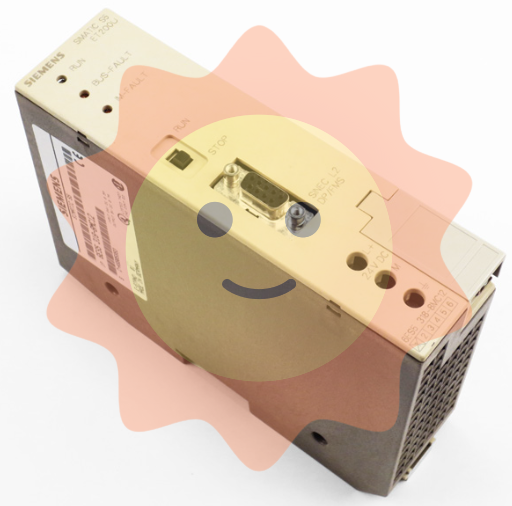

SIEMENS 6ES5318-8MA12: SIMATIC S5 Distributed Interface

Functional Role in SIMATIC S5 Architecture

The SIEMENS 6ES5318-8MA12, commonly referred to as the IM 318 interface module, is a fundamental building block for decentralized automation within the SIMATIC S5-115U and S5-135U/155U series. Its primary purpose is to decouple the central controller from the physical location of the I/O modules, allowing for a more flexible and cost-effective cabinet layout.

In complex industrial plants, the 6ES5318-8MA12 acts as a high-speed communication bridge. It transmits the internal S5 backplane bus signals to expansion racks (ER) located several meters away. By using this interface, engineers can avoid the excessive costs of long-distance sensor wiring by placing I/O racks closer to the actual field instrumentation while maintaining a centralized logic control unit.

Technical Specifications and Data

The following technical parameters outline the electrical and operational characteristics of the 6ES5318-8MA12 as specified in the Siemens SIMATIC S5 hardware documentation:

Parameter Category Technical DetailManufacturer & Family Siemens SIMATIC S5 Series

Article Number 6ES5318-8MA12

Module Designation IM 318 Interface Module

Distance Capability Varies by configuration (up to several meters)

Power Consumption Typically 1.5W from internal bus

Weight Approx. 0.48 kg

Bus Compatibility S5-115U / S5-135U / S5-155U Backplane

Isolation Galvanic isolation between bus segments

Key Operational Features

1. High-Speed Bus Synchronization

The 6ES5318-8MA12 ensures that decentralized expansion racks remain synchronized with the CPU cycle. It features specialized driver circuits that compensate for signal propagation delays across the expansion cables, ensuring that inputs and outputs are updated with microsecond-level precision.

2. Robust Diagnostic LEDs

Maintenance is simplified through the inclusion of front-panel status indicators. These LEDs provide immediate feedback on the health of the bus link and the power status of the module. In the event of a cable break or a loss of communication with the central controller, the module triggers a system interrupt, allowing the CPU to execute safe shutdown procedures.

3. Galvanic Signal Protection

Industrial environments are often subject to electromagnetic interference (EMI) and potential differences. The 6ES5318-8MA12 incorporates galvanic isolation between the central bus and the expansion link. This protects the sensitive central controller from voltage spikes that may occur in distant expansion subracks.

Engineering Requirement: To ensure proper signal integrity, always use the dedicated Siemens S5 shielded connecting cables. The 6ES5318-8MA12 requires a matching receiver module in the expansion rack (typically an IM 314 or similar) to complete the distributed link.

Installation and Configuration Protocols

When integrating the 6ES5318-8MA12 into a SIMATIC S5 rack, specific mounting and wiring standards must be followed to ensure long-term stability:

Slot Selection: The IM 318 must be inserted into the designated interface slots of the central controller subrack.

Grounding: Ensure the subrack is bonded to the common plant ground. The shielding of the expansion cable must be connected to the module housing to drain off EMI.

Addressing: Addressing for decentralized I/O is handled via the CPU configuration. The 6ES5318-8MA12 transparently maps the remote I/O into the process image of the S5 controller.

Typical Industrial Applications

Due to its reliability, the 6ES5318-8MA12 remains in active use across various heavy industrial sectors:

Automotive Assembly Lines

Managing the distributed sensor networks along long conveyor systems where centralized logic must control actuators located hundreds of feet away.

Water Treatment Facilities

Linking remote pump stations and filtration monitors to a central control cabinet without the need for multiple independent PLCs.

Chemical Processing

Operating in environments where sensitive electronics must be kept in controlled rooms while the I/O racks are distributed near the chemical reactors.

Compliance and Lifecycle Maintenance

The SIEMENS 6ES5318-8MA12 is built to endure decades of continuous operation. It complies with VDE 0160 and various industrial EMC directives. For maintenance, it is recommended to periodically check the tightness of the multi-pin connectors and verify that the expansion cables are not subjected to mechanical stress or sharp bends which could degrade signal quality over time.

Model Supplement

- User name Member Level Quantity Specification Purchase Date

- Satisfaction :

-