Moog CD series compact dynamic brushless servo motor

Power density optimization: Compact body design (base size 40 mm-190 mm), combined with 8-12 pole electromagnetic structure, achieves high torque output in a small volume (such as the maximum continuous torque of 74.26 Nm for the G-6 model), saving equipment installation space.

Low cogging torque design: By using asymmetric stator slots, high pole layout, and proprietary magnetic circuit optimization, torque fluctuations during low-speed operation are reduced to ensure smooth operation (such as low-speed high-precision transmission for medical equipment and optical detection platforms).

Environmental adaptability: IP65 protection level (shaft seal optional IP67), working temperature -40 ℃~+125 ℃ (short-term reflow soldering withstand 240 ℃/15s), supporting industrial harsh environments such as high dust and humidity; Some models have passed explosion-proof certification and can be used in hazardous areas.

Moog CD series compact dynamic brushless servo motor

Core product positioning and technological advantages

1. Core features and applicable scenarios

High dynamic response: The rotor has a low moment of inertia (minimum 0.027 kg · cm ²), and the positioning time can be as low as within 30 ms, suitable for dynamic scenarios such as high-speed start stop and precision positioning (such as electronic component assembly robots and laser processing equipment).

Power density optimization: Compact body design (base size 40 mm-190 mm), combined with 8-12 pole electromagnetic structure, achieves high torque output in a small volume (such as the maximum continuous torque of 74.26 Nm for the G-6 model), saving equipment installation space.

Low cogging torque design: By using asymmetric stator slots, high pole layout, and proprietary magnetic circuit optimization, torque fluctuations during low-speed operation are reduced to ensure smooth operation (such as low-speed high-precision transmission for medical equipment and optical detection platforms).

Environmental adaptability: IP65 protection level (shaft seal optional IP67), working temperature -40 ℃~+125 ℃ (short-term reflow soldering withstand 240 ℃/15s), supporting industrial harsh environments such as high dust and humidity; Some models have passed explosion-proof certification and can be used in hazardous areas.

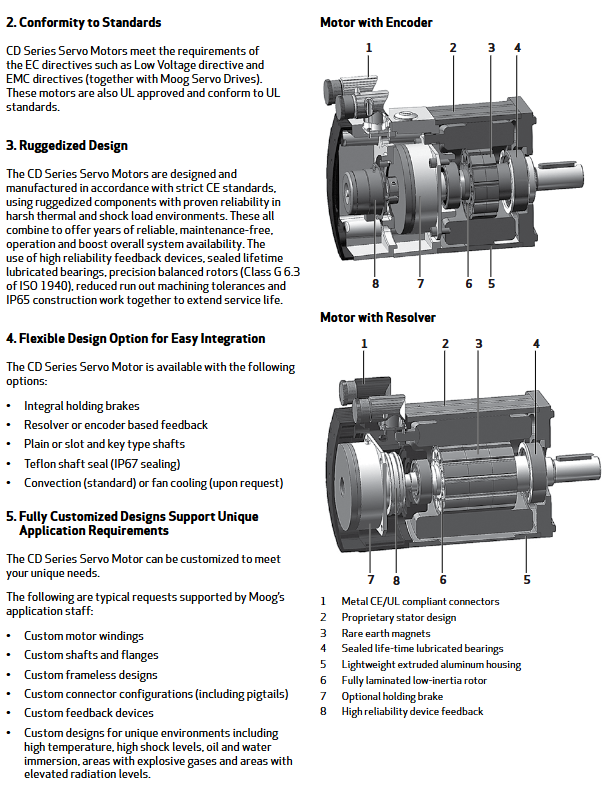

2. Key technological advantages

Dual voltage level adaptation: divided into low voltage version (G-X-M, DC 325 V, equipped with NTC temperature sensor) and high voltage version (G-X-V, DC 565 V, equipped with PTC temperature sensor), adapted to different servo drive power supply requirements, balancing low voltage safety and high voltage efficiency.

Flexible feedback options: Supports rotary transformers (Resolvers, 2-pole, strong anti-interference), incremental encoders (such as Heidenhain ERN series), and absolute encoders (single/multi turn, such as Stegmann SKS series) to meet different accuracy requirements from general positioning to precision closed-loop control.

Long life design: using lifetime lubricated sealed bearings, F-class insulated windings (temperature resistance of 155 ℃), coupled with rotor precision dynamic balancing (ISO 1940 G6.3 level), with a long mean time between failures (MTBF) and reduced maintenance costs.

Product series and technical parameters

1. Machine base size and performance range

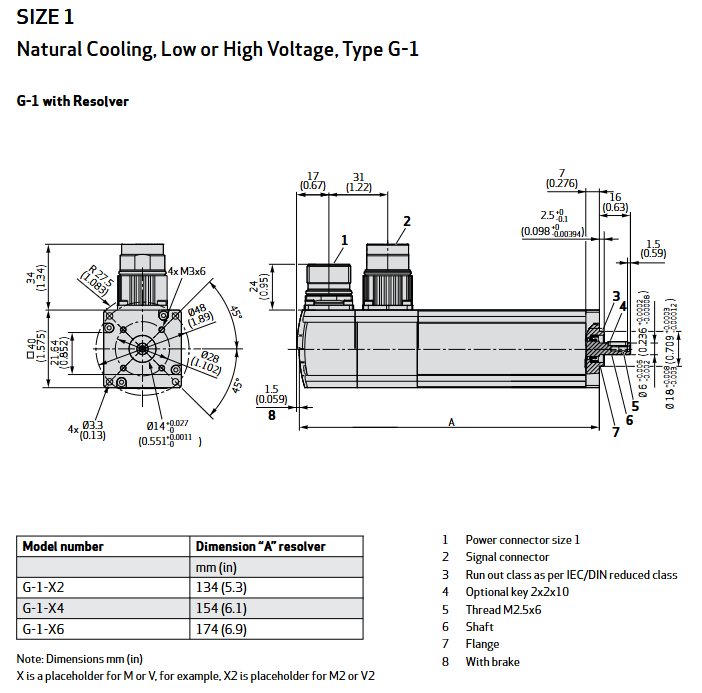

The CD series is divided into 6 models (G-1 to G-6) according to the size of the machine base (flange diameter), and the core parameters of each model cover the following range:

Machine base model, flange size (mm), continuous torque range (Nm), maximum torque range (Nm), rated speed (r/min), rotor moment of inertia (kg · cm ²), weight (kg)

G-1 40 0.16-0.35 0.50-1.51 6000-9000 0.027-0.072 0.55-0.84

G-2 55 0.24-2.02 0.83-6.64 5000-8000 0.070-0.44 1.0-2.3

G-3 70 0.55-3.94 1.72-13.33 3400-11000 0.14-0.97 1.7-3.5

G-4 100 1.25-11.33 3.38-41.40 2600-8000 0.85-7.05 3.0-9.4

G-5 140 5.80-35.17 13.25-94.55 1800-5000 4.51-27.23 7.7-21.0

G-6 190 14.0-74.26 40.25-240.06 2000-4000 27.56-156.98 15.1-44.8

2. Key electrical and mechanical parameters

Electrical performance:

Torque constant (kT): 0.17 Nm/A~2.45 Nm/A (such as G-6-V9 model kT=2.27 Nm/A), high current control accuracy;

Voltage constant (ke): 11.1 Vrms/krpm~145.6 Vrms/krpm, adapted to the back electromotive force requirements at different speeds;

Insulation resistance ≥ 10 ¹² Ω, test voltage 1 kV~3.1 kV (higher for high voltage models), ensuring high voltage safety.

Mechanical properties:

Shaft diameter and keyway: adapted to the size of the machine base (such as G-1 shaft diameter of 6 mm, G-6 shaft diameter of 32 mm), supporting optical axis and keyway shaft (compliant with DIN 6885 standard);

Bearing load: Maximum radial load of 250 N (G-6), maximum axial load of 500 N (G-6), compatible with various transmission modes such as belts and gears;

Cooling methods: natural cooling (standard), forced air cooling (G-4~G-6 optional, increasing continuous torque by 30%).

Flexible configuration and customization options

1. Standard configuration options

The CD series motor supports multi-dimensional standard configurations to meet the needs of different application scenarios:

Braking device: Integrated permanent magnet holding brake (optional 2 torque levels), locks the shaft system after power failure, adapts to vertical axis loads (such as lifting platforms), braking voltage 24 VDC (power 10 W~40 W).

Shaft seal and protection: Standard IP65 (dustproof and waterproof), optional Teflon shaft seal (IP67), suitable for liquid splashing scenarios (such as food processing and cleaning equipment).

Connectors and Wiring: Supports right angle fixing, right angle rotation, and straight connectors, adapting to different installation space wiring requirements; The signal interface distinguishes between power (U/V/W) and feedback (Resolve/Encoder) for easy wiring maintenance.

Temperature monitoring: The low-voltage version is equipped with NTC thermistor (20.489 Ω at 25 ℃), and the high-voltage version is equipped with PTC thermistor (sudden change in resistance at 155 ℃) to monitor the winding temperature in real time and prevent overheating damage.

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor

- SHINKAWA

- Other Brands