REXRTOH CDH1/CGH1/CSH1 series milling machine type hydraulic cylinder

Technical Analysis and Application Guide for Bosch Rexroth CDH1/CGH1/CSH1 Series Hydraulic Cylinder

Product Overview and Series Positioning

Bosch Rexroth, as a leading global supplier of transmission and control technology, has launched the CDH1/CGH1/CSH1 series hydraulic cylinders, which belong to the "Mill Type" industrial hydraulic cylinder category and are designed specifically for industrial applications with high loads, high frequencies, and harsh working conditions. This series of hydraulic cylinders complies with international standards such as ISO 3320 and ISO 6022, with a rated working pressure of up to 250 bar (25 MPa) and a test pressure of up to 375 bar. They are suitable for metallurgy, mining, ships, heavy machinery, presses, and various industrial automation systems.

The three sub series CDH1, CGH1, and CSH1 maintain consistency in their basic structure and adopt differential cylinder design. The piston diameter range covers 40 mm to 320 mm, and the piston rod diameter extends from 22 mm to 220 mm, with a maximum stroke of up to 6 m. The main difference among the three is their functional configuration: CDH1 is the standard type, CGH1 focuses on high dynamic and servo applications, and CSH1 has a built-in magnetostrictive position measurement system, suitable for closed-loop control scenarios that require high-precision position feedback.

Core technology and structural characteristics

1. High voltage bearing and sturdy structure

This series of hydraulic cylinders adopts a flange connected cylinder head and cylinder bottom design, with strong structural rigidity and the ability to withstand high axial and radial loads. The surface of the piston rod is provided with a hard chromium coating or a double-layer treatment option of "hardening+hard chromium", significantly improving wear resistance and corrosion resistance, suitable for harsh environments. The cylinder barrel is made of precision cold drawn steel pipes, and the inner surface is polished to ensure low friction and long service life.

2. Various installation forms

Provide six standardized installation methods to cover the vast majority of industrial installation needs:

MP3/MP5: The base is equipped with joint bearings or self-aligning fork heads, which can compensate for certain installation alignment errors.

MF3/MF4: Front or rear circular flange installation, suitable for fixed high rigidity connections.

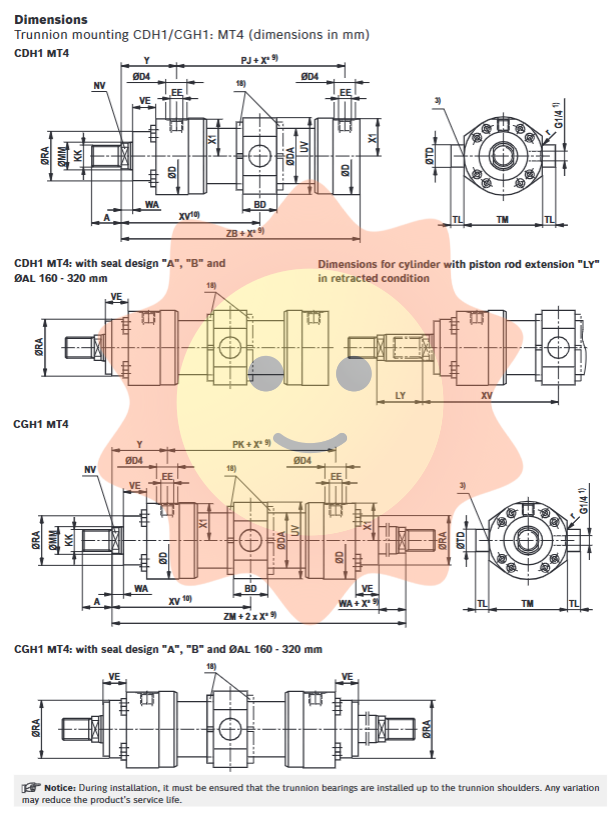

MT4: Ear shaft installation, allowing cylinder body to swing.

MS2: Foot mount installation, fixed to the base with bolts.

3. Intelligent buffering system

Adjustable or self-adjusting buffer devices are integrated at both ends of the cylinder body, effectively reducing the impact at the end of the stroke and protecting the cylinder body and load structure. The buffering performance can be calculated and selected based on load mass, motion speed, and system pressure, especially suitable for high-speed and high inertia applications.

4. Advanced sealing technology

Multiple sealing kit options are provided based on the working medium (mineral oil, water ethylene glycol, phosphate ester, etc.) and operating conditions (temperature, pressure, speed), including standard type, low friction type, heavy-duty type, and servo specific type. Sealing materials include NBR, FKM, etc., ensuring compatibility and long lifespan in different media.

5. Integrated sensing and control interface

The CSH1 series is equipped with a non-contact magnetostrictive displacement sensor that provides analog (4-20 mA, 0-10 V) or digital (SSI, PROFIBUS, IO Link, PROFINET) outputs with a resolution of up to 1 µ m and supports high-precision position closed-loop control.

Optional inductive proximity switch for endpoint position detection.

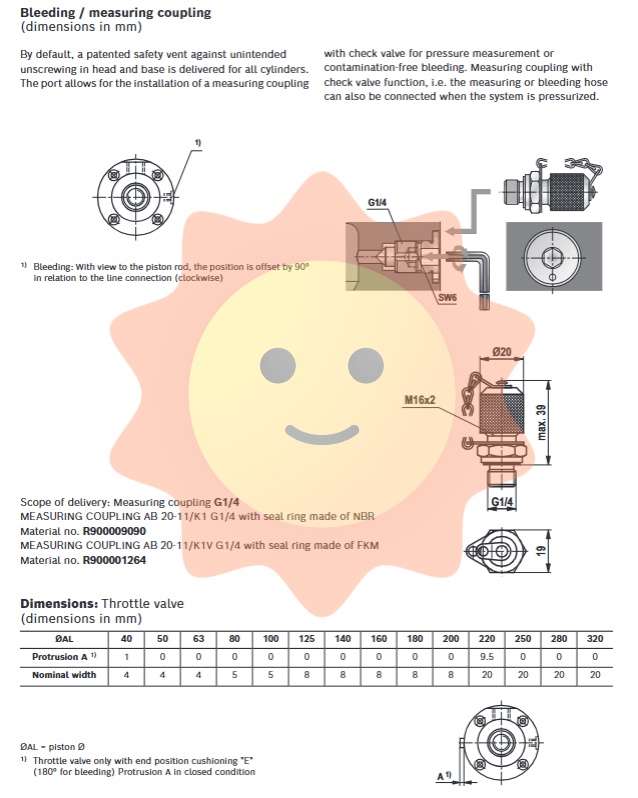

Standard anti loosening exhaust plug, and can be equipped with measuring connector for easy system exhaust and pressure detection.

Key technical parameters and performance

1. Load and force calculation

Based on the piston diameter and system pressure, the theoretical thrust and tension can be accurately calculated. For example, a piston diameter of 100 mm can generate a thrust of approximately 196 kN at a pressure of 250 bar. In actual selection, efficiency, accessory load capacity (such as joint bearings, flanges), and safety factor should be considered.

2. Match motion speed with flow rate

The maximum movement speed of the hydraulic cylinder is limited by the size of the inlet oil circuit and the recommended flow rate (usually 5 m/s). For example, when a piston diameter of 100 mm is paired with a G1 interface, it is recommended that the maximum speed should not exceed 0.20 m/s. Attention should be paid to the possible loss of medium carrying caused by the difference in extension and retraction speed.

3. Bending resistance and stroke verification

The allowable stroke length of hydraulic cylinders is not only limited by mechanical structure, but also requires stability (buckling) verification of the compression rod. The manual provides a calculation method based on Euler and Tetemeyer formulas, and provides detailed safety travel tables for different installation methods (fixed guided, free fixed, etc.) and load angles (0 °, 45 °, 90 °), which is an indispensable part of the selection process.

4. Adaptability to working medium and environment

Hydraulic oil: suitable for HL, HLP mineral oil, HFA, HFC water-based lotion, and HFDR, HFDU synthetic ester.

Temperature range: medium temperature -20 ° C to+80 ° C (depending on the sealing material), ambient temperature -25 ° C to+80 ° C.

Cleanliness: The system oil is required to have a cleanliness level of at least ISO 4406 20/18/15 to ensure the sealing and valve life.

Anti corrosion coating: Provides five levels of corrosion protection from CP3 to CP7, with coating thicknesses ranging from 40 µ m to 320 µ m. It has been certified through salt spray and condensate water tests of different durations, meeting the protection needs from indoor dry environments to coastal high salt spray environments.

Selection, ordering, and configuration

Bosch Rexroth adopts a modular ordering code system, where users need to select a series, installation method, piston diameter, piston rod diameter, stroke, component series, oil port connection form, oil port position, and other parameters in order. In addition, there are abundant additional option fields covering:

Sensor configuration (proximity switch, position measurement system)

Buffer type (none, self-adjusting, adjustable)

End form of piston rod (threaded, assembled joint bearing or fork)

Sealing kit type

Surface treatment and coating grade

Test certificate requirements

This highly flexible system ensures that each hydraulic cylinder can accurately match the specific application needs of users. The company also provides interactive product selection software (ICS), which can quickly generate 3D models, technical drawings, and ordering codes.

Typical application areas

Metallurgical equipment: continuous casting machine, rolling mill pressing device, plate straightening machine, requiring high pressure and high rigidity.

Mining machinery: hydraulic supports, tunneling machine propulsion cylinders, requiring high reliability and environmental adaptability.

Ships and marine engineering: servos, hatch opening and closing, wave compensation systems require corrosion-resistant design and reliable sealing.

Pressure molding: The main cylinder of injection molding machines and presses relies on high-precision position control and smooth buffering.

Energy field: turbine guide vane control, wind power variable pitch system, emphasizing long life and low maintenance.

Automated production line: Material handling and mold replacement require integrated position feedback and bus communication.

Installation, Maintenance, and Safety Guidelines

Installation alignment: It is necessary to ensure that the cylinder body is aligned with the axis of the load movement to avoid lateral forces, otherwise it will cause abnormal wear of the seal and guide components.

Buffer adjustment: For adjustable buffers, fine adjustments should be made during the debugging phase based on actual load and speed to achieve the best buffering effect.

Maintenance: Regularly check the surface of the piston rod for scratches and corrosion, and promptly clean the dirt accumulated on the dust ring. When replacing the seal, the original sealing kit must be used and assembled strictly according to the specified tightening torque.

Safety warning: The hydraulic system has high pressure, and any maintenance work must be carried out by trained personnel after the system is depressurized. Do not adjust the settings of proximity switches or position sensors arbitrarily.

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor

- SHINKAWA