Rockwell Automation ControlLogix 5570 and 5560 controllers

Features ControlLogix 5570 ControlLogix 5560

Power Supply and Memory Backup Energy Storage Module (ESM) Lithium Battery (1756-BA1/BA2/BATM)

Built in communication port USB 2.0 (temporary programming only, cable length ≤ 3m, no hub) RS-232 serial port

The maximum number of connections is 500 and 250

Non volatile storage SD card (standard 1784-SD1 1GB) CompactFlash card (available separately)

Status display: 4-line scrolling text screen+4 indicator lights, 6 indicator lights (no text screen)

Representative models 1756-L71/L72/L73/L74/L75 1756-L61/L62/L63/L64/L65

Rockwell Automation ControlLogix 5570 and 5560 controllers

Product Overview and Classification

1. Controller types and core differences

The ControlLogix series controllers are divided into two major series, 5570 and 5560, as well as extreme environment type (- XT suffix) and Armor protection type (- EROM suffix). The core differences are as follows:

Features ControlLogix 5570 ControlLogix 5560

Power Supply and Memory Backup Energy Storage Module (ESM) Lithium Battery (1756-BA1/BA2/BATM)

Built in communication port USB 2.0 (temporary programming only, cable length ≤ 3m, no hub) RS-232 serial port

The maximum number of connections is 500 and 250

Non volatile storage SD card (standard 1784-SD1 1GB) CompactFlash card (available separately)

Status display: 4-line scrolling text screen+4 indicator lights, 6 indicator lights (no text screen)

Representative models 1756-L71/L72/L73/L74/L75 1756-L61/L62/L63/L64/L65

2. Special Model Description

Extreme environment type (- XT): such as 1756-L73XT/L63XT, supports working temperatures of -25~+70 ° C, and other functions are consistent with the corresponding basic model.

Armor protective type (- ROM): such as 1756-L72EROM/L73EROM, integrated with 1756-L7x controller and 2 EtherNet/IP DLR communication modules, IP67 protection level, suitable for machine installation, ESM non removable.

Installation and hardware configuration

1. Installation environment requirements

Environmental conditions: Pollution level 2 industrial environment, overvoltage category II, altitude ≤ 2000m, no derating requirements; Storage temperature -40~+80 ° C, working temperature for conventional type 0~+60 ° C, extreme type -25~+70 ° C.

Shell requirements: It needs to be installed in a shell that complies with NEMA 250 or IEC 60529 standards, with a flame retardant rating of 5VA (non-metallic shells need to be certified), and can only be opened with tools inside. The explosion-proof environment needs to additionally comply with ATEX/IECEx requirements (such as Zone 2 environment requiring an IP54 or above shell).

2. Core hardware installation steps

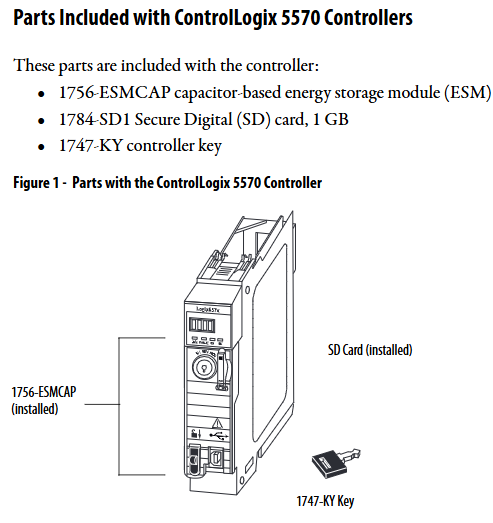

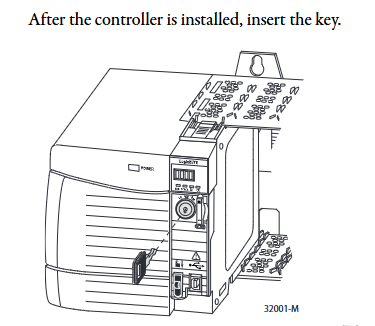

(1) Key installation of ControlLogix 5570

**Chassis and power supply pre installation * *: Chassis and power supply need to be installed according to the manuals "1756-IN621 (Chassis)" and "1756-IN619 (Power Supply)" first.

Controller insertion: Align the upper and lower rails of the chassis, slide in to the buckle lock, and ensure that it is flush with adjacent modules; Attention should be paid to the risk of electric arc in explosion-proof environment during live plugging and unplugging. It is recommended to perform power-off operation.

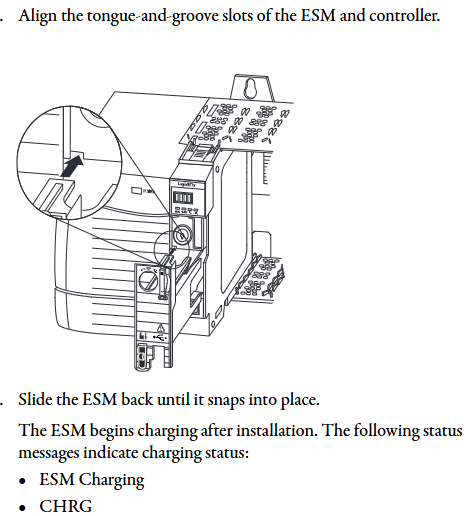

ESM installation: Align with the tongue and grain slot and push it into the buckle for fixation. After installation, start charging (up to 2 minutes, the status screen displays "CHRG"). Do not turn off the power before charging is complete, otherwise the program may be lost.

SD card operation: Open the SD card card, insert the 1784-SD1/SD2 card (recommended original card to avoid data damage), and press it until the card buckle locks; Before removal, it is necessary to confirm that the SD indicator light is off and that the explosion-proof environment requires power-off operation.

(2) Key installation of ControlLogix 5560

Battery installation: Series A uses 1756-BA1/BATM, Series B uses 1756-BA2, connect the positive and negative poles (red+black -), write the replacement date and paste it on the inside of the cabinet door.

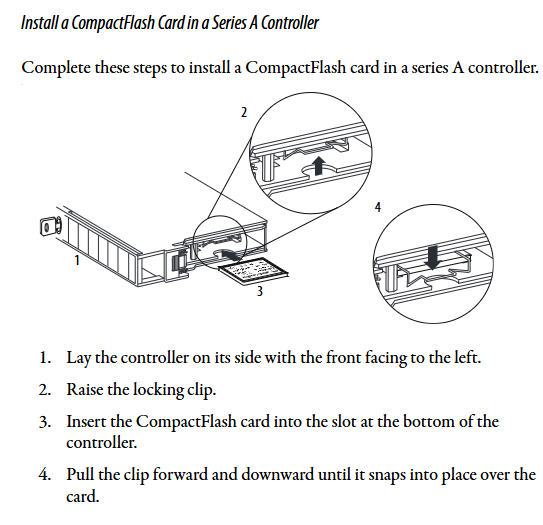

CompactFlash card operation: Series A needs to lift the locking clip to insert, Series B needs to push open the buckle and insert, and before removing, confirm that the OK indicator light is green.

3. Hardware security specifications

Static protection: Before operation, touch grounded objects to discharge electricity, wear a grounding wristband, avoid touching connector pins and internal circuits, and use anti-static workstation storage devices.

Explosion proof requirements: In Class I Zone 2 (Groups A-D) environments, equipment/components can only be plugged in and out after power failure or confirmation of non hazardous areas; It is prohibited to replace non certified components, and batteries must be replaced in non hazardous areas.

Software configuration and firmware upgrade

1. Essential software and version requirements

Different controller models need to be matched with specific software versions, and the core requirements are as follows:

Controller model Studio 5000 environment minimum version RSLogix 5000 minimum version RSLinx Classic minimum version

1756-L71/L72/L73 and other V21.00.00 V20.01.02 V2.59.00

1756-L61/A - V12.06.00 any version

1756-L63XT/B - V13.04.00 V2.55.00

2. Firmware upgrade method

Supports two methods: ControlFLASH software and AutoFlash (built-in in Logix Designer). The steps are as follows:

(1) ControlFLASH upgrade

Connect the controller (USB/Ethernet), start ControlFLASH, select the controller model and network driver.

Select the target firmware version (download the matching version from the official website to avoid file corruption), click "Finish" to start the upgrade, and do not turn off the power during the process.

After the upgrade is completed, the controller automatically restarts and the confirmation status screen displays the new firmware version (such as "Rev 30.011").

(2) AutoFlash upgrade

Create a project in Logix Designer, click on "Who Active" to find the target controller, and select "Update Firmware".

Select the firmware file path and version, confirm that the controller is in "Remote Program" mode and there are no uncleared faults, and click "Update".

During the upgrade process, the progress is displayed (5570 points for "update count/block count", 5560 only displays "block count"), and the firmware version is verified after completion.

3. Memory and storage configuration

5570 series: SD cards are used to store project and fault logs, supporting three modes: "power on load", "load when memory is damaged", and "user triggered load". Locking the SD card can prevent firmware from being overwritten.

5560 series: The CompactFlash card needs to be configured with the "store/load" parameter in Logix Designer, supporting program backup and recovery. When replacing the battery, ensure that there is a backup in the card to prevent data loss.

Communication network configuration

1. Supported communication protocols and modules

The controller supports multiple types of industrial networks and requires corresponding communication modules. The core configuration is as follows:

Network type, communication module model, core function, maximum number of connections/bandwidth limit

EtherNet/IP 1756-ENBT/EN2TR/EN3TR supports production and consumption tags, I/O control, and HMI communication. 1756-EN3TR supports 256 movements in 128 axes (EN2T/EN2TR); 128 (ENBT)

ControlNet 1756-CNB/CN2/CN2R/CN2RXT deterministic real-time communication, supporting 64 redundant media (CN2R/CN2RXT) (CNB/CNBR); 128 (CN2/CN2R)

DeviceNet 1756-DNB connects distributed I/O and drivers, supports scanning list configuration with 124 DINT input/123 DINT output

Data Highway Plus (DH+) 1756-DHRIO/DHRIOXT connects PLC-5/SLC controllers, supporting 32 sites at 57.6/115.2/230.4 kbps rates

HART 1756-IF8H/OF8H analog I/O+digital signal superposition, supports direct connection to HART transmitter for device diagnosis

2. Key steps for communication configuration

(1) EtherNet/IP configuration

Add modules such as 1756-EN2T in the "I/O Configuration" of Logix Designer and set the IP address (supporting BOOTP/DHCP allocation).

Configure "Production/Consumption Tags": Production tags need to specify the number of consumers, while consumption tags need to match the production tag data type and RPI (Request Packet Interval).

Remote I/O configuration: Reduce the number of connections through "rack optimization connections", and a single connection can cover the entire remote rack I/O.

(2) Serial Communication (5560 Series)

Connect the 1756-CP3 serial port cable, configure the "RS-232 DF1 device driver" in RSLinx, and select the "Logix 5550/CompactLogix" device type.

Supporting protocols: DF1 master-slave/point-to-point/wireless modem, DH-485, ASCII, Modbus (requiring MSG instruction programming), ASCII protocol requires configuring buffer size (1-4096 bytes) and termination characters.

Programming and Application Development

1. Control program structure

The Logix 5000 control program consists of a three-level structure of "task program routine", with the following core rules:

Tasks (up to 32):

Continuous task (1): lowest priority, utilizing idle CPU time for cyclic execution.

Periodic task: Execute at set intervals (0.1~2000000ms), priority 1~15 (highest 1).

Event task: triggered by triggering conditions (such as I/O status changes, consumption tag triggers) for execution.

Program (up to 1000 per task, V24+): Contains local tags, parameters, main routines, fault routines, supports "scheduled execution" (executed in sequence) and "unplanned execution" (only verified and not running).

Routine: executable code written in a single programming language, supporting ladder diagrams (LD), function block diagrams (FBD), structured text (ST), and sequential function diagrams (SFC).

2. Core programming functions

(1) Production/Consumption Tags (Interlock Data)

Production label: One controller releases data, and multiple controllers (up to 32) consume it simultaneously. It must be on the same network (not bridged across networks), and the data type and array dimension must be consistent.

Connection calculation: The production label occupies "number of consumers+1" controller connection, the consumption label occupies 1 connection, and the communication module occupies an additional 1 connection.

(2) MSG instruction (message communication)

Supports types such as "CIP Data Table Read/Write", "PLC-5/SLC Communication", "General CIP", etc. It can cache connections (optimize speed during repeated execution, up to 32 cache connections) or non cache connections (release connections after execution).

Block Transfer requires the configuration of a "request/response" data area, which is suitable for high-speed counters, frequency converters, and other devices.

(3) Motion control

Supports EtherNet/IP integrated motion (Kinetix 350/5500/6500 drivers), Sercos interface (1756-M03SE/M08SE module), and analog interface (1756-HYD02 module).

Core instructions: MSO (servo enable), MAH (axis return to zero), MAJ (axis jog), MAM (axis positioning), need to create "axis labels" and configure parameters such as speed and acceleration.

3. PhaseManager tool (device phase control)

Function: Divide device operation stages (such as Resetting/Running/Holding) according to the S88/Pack ML state model, simplify process programming, support "action state" (executing operations) and "waiting state" (waiting when conditions are met).

Core instructions: PSC (Stage Completion Signal), PCMD (Stage State Switching), PFL (Stage Fault Signal), which need to be enabled in Logix Designer V21+and support multitasking scheduling.

Troubleshooting and Maintenance

1. Status indicator lights and fault diagnosis

(1) Interpretation of the 5570 series status

OK indicator light: evergreen (normal), flashing red (new controller requires firmware upgrade/major fault), constantly red (power on diagnosis/ESM discharge/program loading).

SD indicator light: flashing green (read/write in progress), constantly red (card not recognized), flashing red (file system invalid).

Fault message: The text screen displays "Major Fault Txx: Cxx" (major fault type/code) and "I/O Fault Local: X # XXXX" (I/O fault location/code), such as T04: C42 indicating "invalid JMP target".

(2) Interpretation of the 5560 series status

BAT indicator light: constantly red (battery missing/95% discharged), evergreen (program saved when B series is powered off).

I/O indicator light: flashing green (some I/O is unresponsive), flashing red (chassis fault).

2. Common fault handling

Possible causes and solutions for the fault phenomenon

ESM charging failed (CHRG flashing) ESM model incompatible/hardware failure confirmed ESM is 1756-ESMCAP/ESMNSE series, replace faulty ESM

SD card cannot read or write non original card/card lock/file system damage using 1784-SD1/SD2, unlock card, format or replace card

Serial communication timeout line length exceeds 15.2m/baud rate mismatch/wiring error. Shorten the line length, confirm baud rates such as 9600/19200, and check TX/RX wiring

I/O connection fault (# 0203) RPI set too low/network interference increases RPI to 20ms or more, check shield grounding, reduce network load

3. Maintain standards

Battery maintenance (5560 series): Replace according to the ambient temperature (e.g. 3 years for 36-40 ° C and 8 months for 56-70 ° C), store at -45~+85 ° C (≤ 30 days), and avoid long-term storage beyond 60 ° C.

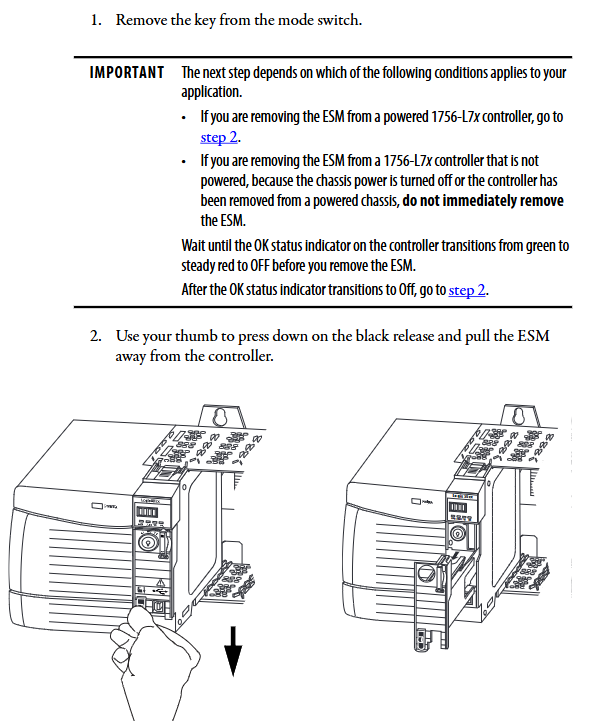

ESM maintenance (5570 series): 1756-ESMCAP supports 12 day (20 ° C) WallClockTime backup. Before replacement, power off and wait for the OK light to turn off (to release residual energy). Armor type ESM cannot be replaced.

Cleaning and Storage: Use a soft cloth and mild cleaning agent to clean the outer shell. For long-term storage, it should be placed in anti-static packaging with an ambient temperature of -40~+80 ° C and humidity of 40~60%.

Appendix and Compliance

1. Compliance standards

Electrical safety: Complies with EN 60664-1 (overvoltage category II) and EN 60068-2 (environmental testing).

Explosion proof certification: ATEX II 1/2G Ex ia IIC T5, IECEx Ex ia IIC T5, CSA C/US Class I Div.1.

EMC: Compliant with EN 61326 (anti-interference in industrial environments), EMC impact<1% of full scale.

2. Key documents and resources

Supporting manuals: "1756-TD001 (Technical Parameters)", "1756-PM011 (Production and Consumption Labels)", "1756-PM014 (Fault Handling)".

Download resources: firmware, EDS files, DTM tools can be obtained from the Rockwell official website's "Product Compatibility and Download Center" (rok. auto/pcdc).

Environmental requirements: Equipment scrap must be classified and recycled according to the WEEE directive, and lithium batteries must not be mixed with household waste and must be collected and disposed of separately.

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor

- SHINKAWA

- Other Brands